[FIXED] 2005 Mazda 3S - Throttle Response Problem

- jcascel1

-

Topic Author

- Offline

- Junior Member

-

- DIY'er not a Pro

- Posts: 38

- Thank you received: 7

I videoed the entire timing process. I had hoped for it to be a tutorial however it ended up just being me talking to myself as I worked my way through the process. It's torture to watch so I probably won't post it here although it will be on my YT channel in case it might help someone. At the 10 minute mark I took a look, pre-adjustment, at the cam timing relative to TDC since someone here was curious as to what it looked like. If you want to spare yourself the torture of listening to me babble to myself, you can skip to the last clip in the video to see the rather successful outcome of the timing process. BTW, engine vacuum now measures 21inHg.

Configuration is:

2011 Ford Fusion 2.5 long block.

2.5 intake manifold

2.3 injectors

2.3 TB

2.5 to 2.3 intake to TB adapter

2.5 coils

2.5 egr valve

2.5 OCV

5 spoke intake camshaft timing wheel off of the 2.3 transferred over to the 2.5 intake camshaft

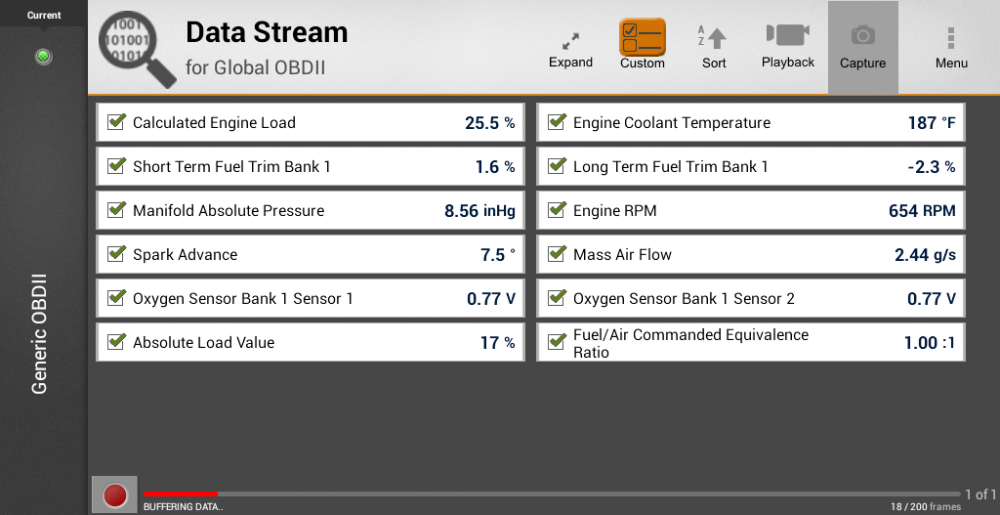

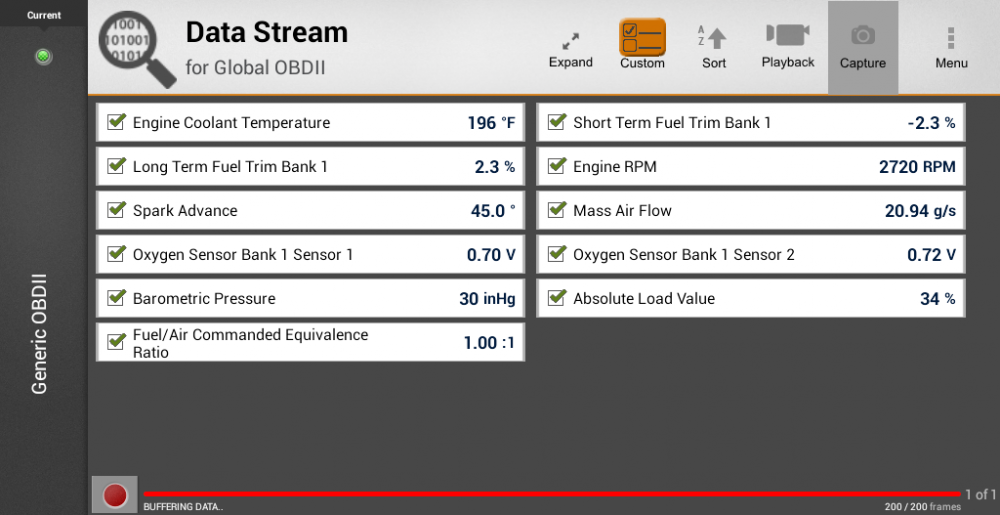

Below are some PID's at idle and tooling along at around 55 mph.

Thank you ALL so very much for your help and encouragement. I consider my interaction with you guys one of the most satisfying parts of this entire experience.

Thanks,

John

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6090

- Thank you received: 1538

The vacuum reading and the scan data look excellent. Those fuel trims are tough to beat

Couple conclusions I drew from this, for my own purposes, up for debate:

1.) No TAC codes, no problem. I really hate broad generalizations like this, but I've never seen a TAC problem that didn't have associated codes, and this Mazda just reinforced that trend. The only exception I can think of would be dirty throttle plates. Really, the only reason I went down that path in this case was due to the engine swap. But overall, I say that if there's no codes, then the throttle is doing what it's told to do.

2.) No P0340? Skip the cam/crank. All the research I did on this 2.3L (iATN, Mitchell, ect.) said that, if the tone wheels were out of time, then you'd get a P0340 code almost immediately. The tone wheels were lined up in this case, so the PCM was happy. For me, the short answer is if there's no P0340, then the tone wheels are lined up. Period. That doesn't mean that the engine is mechanically timed correctly, it just means that I know to skip the cam/crank and go directly to another test.

Seriously, congratulations on making this swap work!

Please Log in or Create an account to join the conversation.

- Interrupt

-

- Offline

- New Member

-

- Posts: 16

- Thank you received: 3

Seriously, congratulations on making this swap work!

None of this was easy. On the bright side, most other timing belt/chain jobs are gonna look like cakework after this :lol:

I second this......well done!!

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4992

- Thank you received: 1115

Great work all around..Seriously, congratulations on making this swap work!

None of this was easy. On the bright side, most other timing belt/chain jobs are gonna look like cakework after this :lol:

I second this......well done!!

I wonder how far out the notch in the crank was that the first guy used to time the engine.

It still started and ran, so it must have been relatively close, right?

Also, do you plan to go back to the larger injectors now that it's running right?

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- jcascel1

-

Topic Author

- Offline

- Junior Member

-

- DIY'er not a Pro

- Posts: 38

- Thank you received: 7

I know, ST/LT trims = ~0% with this mishmash setup - holy hell! I surely wasn’t expecting that. Otherwise, other PID’s are to spec including engine load at ~18%. I’d be interested in knowing how/why load is calculated differently as well.“Those fuel trims are tough to beat

I really like that the Engine Load is much closer to the 2.3L data I posted earlier. Also, I hadn't noticed the Calculated AND Absolute Load PIDs on the Global side... :huh: Gotta look that up. Wondering how/why they calculate them differently.”

Out of my league here but willing to speculate nonetheless. So, got to agree here. Given the systems importance and built in redundancies, I’d imagine that code criteria is fairly tight.“1.) No TAC codes, no problem…………”

Yes, agree! From years of Mazda 3/6 forum watching here’s what I’ve seen most. Concern is a P0340. Customer immediately swaps cam sensor to no avail. Customer then takes car to a ‘shop’ who may sometimes do the ‘clear codes, plugs, and wires’ routine. Customer then takes the car to a Mazda dealer who diagnoses the problem as a base timing issue. Big bucks here since timing cover must be removed to re-time completely.“2.) No P0340? Skip the cam/crank. All the research I did on this 2.3L (iATN, Mitchell, ect.) said that, if the tone wheels were out of time, then you'd get a P0340 code almost immediately. The tone wheels were lined up in this case, so the PCM was happy. For me, the short answer is if there's no P0340, then the tone wheels are lined up. Period…….”

From my research, it appears that some years of the 2.3 production did not include the diamond coated washers between the camshafts and the cam gears. Hence, loose cam bolts and slipped cam timing. Predominantly on intake cams it seems. Timing fix calls for installation of the diamond coated washers.

This was always a weak area for me. With the advent of in cylinder pressure transducers and the ensuing waveform analysis I’ve been intrigued and also able to make more sense of what’s happening. Visual aids – Yes! Now, I have first hand trial by fire experience as well. Wish I had a Pico and transducer to play with!“On the bright side, most other timing belt/chain jobs are gonna look like cakework after this :lol:”

Thanks,

John

Please Log in or Create an account to join the conversation.

- jcascel1

-

Topic Author

- Offline

- Junior Member

-

- DIY'er not a Pro

- Posts: 38

- Thank you received: 7

Thank you very much Sir!“I second this well done!!”

Thanks,

John

Please Log in or Create an account to join the conversation.

- jcascel1

-

Topic Author

- Offline

- Junior Member

-

- DIY'er not a Pro

- Posts: 38

- Thank you received: 7

Notch in the crank? I wish there was one!“I wonder how far out the notch in the crank was that the first guy used to time the engine. It still started and ran, so it must have been relatively close, right?”

Yes, definitely close. I recall you asking about this earlier. In my video I specifically looked at this for you. It was hard to get a good angle on the cams/plate but you could clearly see cam timing was off at TDC. (cam timing plate was impossible to insert) I’m very hesitant to post my video here since it’s pretty much unbearable to watch. I don’t know how to post a link here without it pasting the entire video in. Otherwise, I’d say watch from ~10:25 minutes to ~12:26 minutes into the video to see me showing them as being off. At around 32:35 I show the sweet final fit of the timing plate in the cams! lol

I don’t know how to quantify how far off it was. The pulley was two teeth off so could we say roughly 20 degrees? (35 teeth with one missing 9 teeth prior to TDC) Not sure though and probably no way to know without a Pico/transducer setup.

Here’s what I think happened. Part of the timing procedure requires you to turn the crank with the pulley removed so it will turn independently of the cam timing gear. Normally you turn the crank with the crank pulley bolt in the end of the crankshaft, otherwise you spin it via the flywheel. If you use the bolt you ultimately have to remove it at some point. However, it’s a bit cinched down against the crankshaft. If you’re not careful, upon removal, the crank spins backwards a bit altering the timing. Yes, it could easily be a tooth or two. It happened to me but I caught it and made up for the shift via flywheel movement back to TDC.

Guy who timed it never accounted for this movement. I recall it quite clearly. He then made an incredibly feeble attempt to tighten the bolt down with, get this, one single blip of the trigger on an electric impact! I questioned him and he said, “You have no idea how much power these electric impacts have, that’s way more than 75ft/lbs and a quarter turn.” WTF! The fault is ultimately mine since I trusted him despite my instincts to the contrary. Ugh.

Well, I’m conflicted about it given the current ~0% LT/FT trims. Could it be any better? This wasn’t a performance build I’m embarrassed to admit. I’m impressed by the Mazda PCM’s ability to adjust to this mishmash setup. Naturally, I’m curious and might give the 2.5 injectors a try since the PCM might be able to optimize them as well.“ Also, do you plan to go back to the larger injectors now that it's running right?”

One swapper reports that use of the 2.5 injectors works particularly well with a Mazdaspeed 3/6 or CX7 turbo TB. It’s a direct bolt on to the 2.5 intake manifold. Unless I can get a turbo TB pretty cheap, I’m not rushing into it since I don’t have any information about what the difference in the turbo/non-turbo TB’s is other than perhaps slightly larger bore size. That’s probably enough to justify it, but I need to know more first.

What would you do?

Thanks,

John

Please Log in or Create an account to join the conversation.

- jcascel1

-

Topic Author

- Offline

- Junior Member

-

- DIY'er not a Pro

- Posts: 38

- Thank you received: 7

Thanks,

John

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6090

- Thank you received: 1538

Yes, agree! From years of Mazda 3/6 forum watching here’s what I’ve seen most. Concern is a P0340. Customer immediately swaps cam sensor to no avail. Customer then takes car to a ‘shop’ who may sometimes do the ‘clear codes, plugs, and wires’ routine. Customer then takes the car to a Mazda dealer who diagnoses the problem as a base timing issue. Big bucks here since timing cover must be removed to re-time completely.

:lol: Yeah, that sounds about right!

This was always a weak area for me. With the advent of in cylinder pressure transducers and the ensuing waveform analysis I’ve been intrigued and also able to make more sense of what’s happening. Visual aids – Yes! Now, I have first hand trial by fire experience as well. Wish I had a Pico and transducer to play with!

I would have been interested to see this, too. Double check me here, but I believe that the ACTUAL crankshaft is advanced of the balancer (TDC #1 happens before the ninth tooth on the balancer), and therefore advanced compared to the camshafts. This may have been visible on an in-cylinder capture as an incomplete decompression stroke.

I'll be honest, I have an in-cylinder transducer, and I'm still not great at spotting timing problems with it.

Well, I’m conflicted about it given the current ~0% LT/FT trims. Could it be any better? This wasn’t a performance build I’m embarrassed to admit. I’m impressed by the Mazda PCM’s ability to adjust to this mishmash setup. Naturally, I’m curious and might give the 2.5 injectors a try since the PCM might be able to optimize them as well.

Same, I'm VERY impressed with how well this worked out. I initially thought the higher displacement would screw everything up, but I think the PCM just accounts for it with a higher MAF reading.

I don't know that the 2.5L injectors would make much of a difference? 'Cause the PCM is gonna see the extra fuel the bigger injectors provide, and just trim it back out. Right? :huh: :lol:

Please Log in or Create an account to join the conversation.

- jcascel1

-

Topic Author

- Offline

- Junior Member

-

- DIY'er not a Pro

- Posts: 38

- Thank you received: 7

I've been thinking about this and must confess that I can't say. Well wait, yes, maybe I can. With #1 at TDC the actual crankshaft is advanced of the balancer by two teeth, so 20 degrees advanced of the camshafts. TDC happens at the 7th tooth. (See video just posted.)Double check me here, but I believe that the ACTUAL crankshaft is advanced of the balancer (TDC #1 happens before the ninth tooth on the balancer), and therefore advanced compared to the camshafts.

But the MAF at idle is the same, ~2.4g/s.Same, I'm VERY impressed with how well this worked out. I initially thought the higher displacement would screw everything up, but I think the PCM just accounts for it with a higher MAF reading.

Well, we saw at idle, pre timing fix, that the LTFT was -20%. STFT was around 0%. So, yeah that's what I'm thinking too, PCM will just trim it out. Wondering now though, what difference there would be with proper timing and efficient combustion? Hmmm.I don't know that the 2.5L injectors would make much of a difference? 'Cause the PCM is gonna see the extra fuel the bigger injectors provide, and just trim it back out. Right? :huh: :lol:

Thanks,

John

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4992

- Thank you received: 1115

undeniable evidence.jcascel1 wrote: Here is a SHORT clip of me checking the timing prior to any adjustments. I hope it's clear enough to help show how far it was out. Not much, but definitely enough!

As far as what I would do with the injectors, well, I'm an animal. First thought is "burn more gas!" natrually.

But in reality, I doubt you'd see any difference. The PCM is still in control of fuel delivery, even with a higher flow injector, I'm sure it would just give a shorter injector pulse and negative trims.

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- jcascel1

-

Topic Author

- Offline

- Junior Member

-

- DIY'er not a Pro

- Posts: 38

- Thank you received: 7

undeniable evidence. As far as what I would do with the injectors, well, I'm an animal. First thought is "burn more gas!" natrually.But in reality, I doubt you'd see any difference. The PCM is still in control of fuel delivery, even with a higher flow injector, I'm sure it would just give a shorter injector pulse and negative trims.

Yes, I'm afraid it's true, the PCM is in control! I'll be watching the forums and toying with the idea of the 2.5 injectors and turbo TB. If I find a nice Mazdaspeed 3/6 or turbo CX7 sitting in the junkyard during one of my visits I'll probably grab the TB for future experimentation!

Thanks,

John

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6090

- Thank you received: 1538

Noah wrote: As far as what I would do with the injectors, well, I'm an animal. First thought is "burn more gas!" natrually.

But in reality, I doubt you'd see any difference. The PCM is still in control of fuel delivery, even with a higher flow injector, I'm sure it would just give a shorter injector pulse and negative trims.

:lol: :lol: :lol: Naturally!

Please Log in or Create an account to join the conversation.