[FIXED] 2005 Mazda 3S - Throttle Response Problem

- jcascel1

-

Topic Author

- Offline

- Junior Member

-

- DIY'er not a Pro

- Posts: 38

- Thank you received: 7

Hi all. I've swapped a 2011 Ford Fusion 2.5 in place of the worn out 2.3 in my Mazda 3. Post swap the engine runs and idles but the throttle response is off. It's bad enough to prevent me from driving the car. For the first 1/3 of the pedal travel there is no response. After that point I get response but it's not linear. If I put the trans in gear, the engine bogs and throttle response is even worse. Take it out of gear and bog is gone but throttle response is still off.

I used the 2.5 long block and put all of the 2.3 sensors on it. With the following exceptions, the swap is all 2.3 sensors, wiring harness, and ECM. Remaining from the 2.5 are, injectors, EGR, intake manifold, OCV, and water pump.

Car starts and idles fine. All systems work properly (A/C, cluster, radio, lights, etc.) No CEL is displayed and there are no engine codes. There are codes stored in other modules (steering, GEM, ABS.)

I have verified all connections and grounds. Verified 5v ref and ground as present on all sensors. I've verified grounds and all voltages present at the ECM. Using my Vantage Pro, I've verified the operation of all sensors.

Monitoring PIDs with my Encore, the TB and APP are operating properly according to the info that I have. MAF, MAP, IAT, ECT, O2's, all check out okay. I've checked for intake/exhaust restrictions, vacuum leaks, connections, grounds, fuses, relays, etc,.

Things that stand out that I've used for direction:

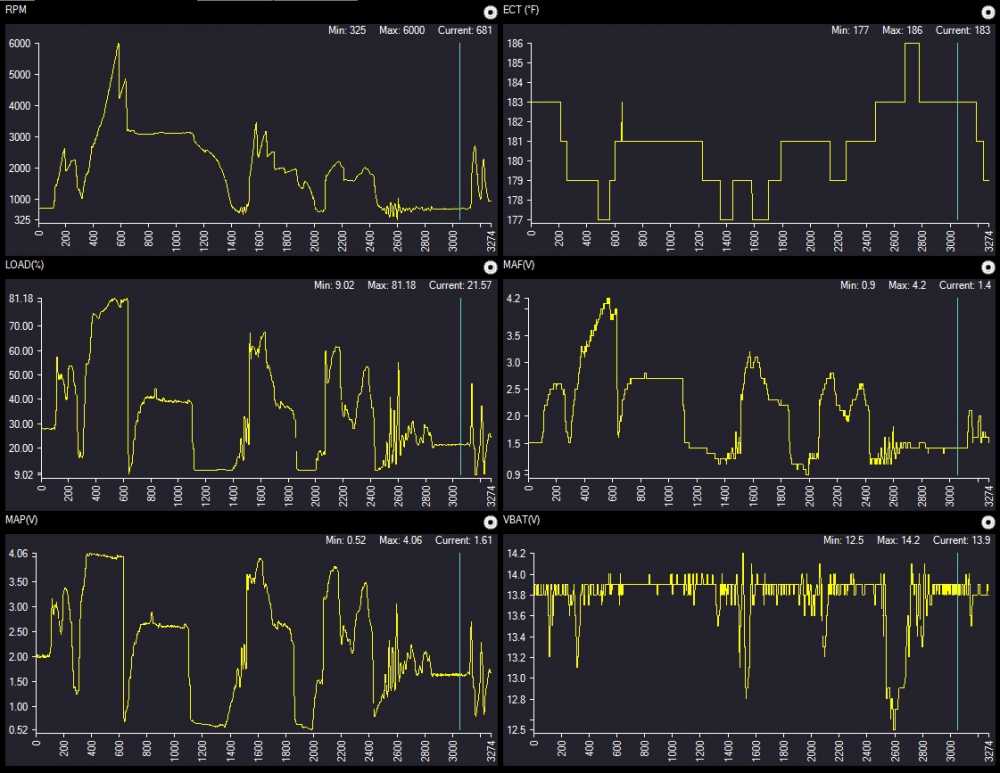

1) Engine Load PID shows ~35% at idle! Here, I'm expecting closer to ~18%. When I am able to get the revs up, the Engine Load climbs to +50%.

2) MAF g/s show to be 4.2g/s when I'm expecting closer to 2.5g/s.

3) Using Global OBD the up and downstream O2 performance is normal. O2's are new with the swap. (Using the factory module on the Encore, the O2's do not show up as active.)

4) Fuel trims show the ST at ~0 and LT on the high side at -20. This does not surprise me though given use of the 2.5 injectors. Fuel system is in closed loop shortly after a warm up and engine reaches operating temp normally.

5) Does not run better with the MAF disconnected.

Direction for me has been troubleshooting:

1) Sensor related issues such as MAF/IAT and MAP. Looking at the MAF signal with the Vantage I get the expected spike with a throttle snap but then the signal flat lines. However the MAF checks out good.

2) The O2's. Everything checks out good. With a throttle snap or some pedal pumping, the upstream goes rich and then lean after decel. Downstream acts accordingly. During idle, upstream and downstream appear normal and within the expected range.

3) TB & APP systems. TB responds to APP inputs. APP fails according to a Vantage component check in the following respect; Measuring duty cycle and voltage per the Vantage at the pedal I see that the duty cycle stays at zero till the voltage gets to a minimum of .8v and then goes right to 50% duty cycle. Continuing, as the voltage climbs the duty cycle hits 100%. Closing the throttle, the duty cycle drops off at 50% right to 0% right after dropping below the .8v point. Swapping the APP sensor gives no change. APP voltage levels measured at the ECM are in spec. Otherwise, I can't find any faults.

I have another Mazda with the 2.3 and so have some spare parts. Things I've tried using my spares are: MAF, MAP, TB, and APP.

Any direction other than that already attempted is appreciated. Thanks!

Thanks,

John

Please Log in or Create an account to join the conversation.

- jcascel1

-

Topic Author

- Offline

- Junior Member

-

- DIY'er not a Pro

- Posts: 38

- Thank you received: 7

Both O2's are new since I also put in a new cat. Today, I'm spending some time looking at them more closely.

Update: Upstream O2 is functioning normally. Signal at ECM is present and looking good. Using the Vantage, I monitored the upstream O2 and an injector. Watching both while enriching the mixture (brake clean) the injector pulse width decreases and O2 voltage increases. All seems to be working well here.

Thanks!

Thanks,

John

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6090

- Thank you received: 1538

My first thought is to stay with the throttle and the lack of response. I see that you've already tried swapping the throttle body from the 2.3L onto the 2.5L intake manifold, good move! I'm really interested in how the ECM's command of the throttle motor behaved:

3) TB & APP systems. TB responds to APP inputs. APP fails according to a Vantage component check in the following respect; Measuring duty cycle and voltage per the Vantage at the pedal I see that the duty cycle stays at zero till the voltage gets to a minimum of .8v and then goes right to 50% duty cycle. Continuing, as the voltage climbs the duty cycle hits 100%. Closing the throttle, the duty cycle drops off at 50% right to 0% right after dropping below the .8v point. Swapping the APP sensor gives no change. APP voltage levels measured at the ECM are in spec. Otherwise, I can't find any faults.

I'd be interested to know how the throttle butterfly itself behaves while stepping on the APP, key on engine off. If the same hesitation can be observed in the butterfly movement, then I'd say we stay with an electronic throttle issue, and move away from other inputs. If the butterfly responds normally with the engine off, but misbehaves with the engine running, then let's go towards another input.

I'm looking at the Troubleshooter, and this APP sensor is weird :blink: APP1 really IS a duty cycle signal, while APP2 is a conventional potentiometer. WTF Mazda? From the Troubleshooter:

KOEO, with throttle fully closed

APP #1 Duty should be 8%

APP #2 voltage should be 1.0 VDC

Just based on this, it kinda sounds like both are misbehaving at closed throttle, as the APP2 signal isn't high enough, and APP1 should be showing a duty cycle off zero

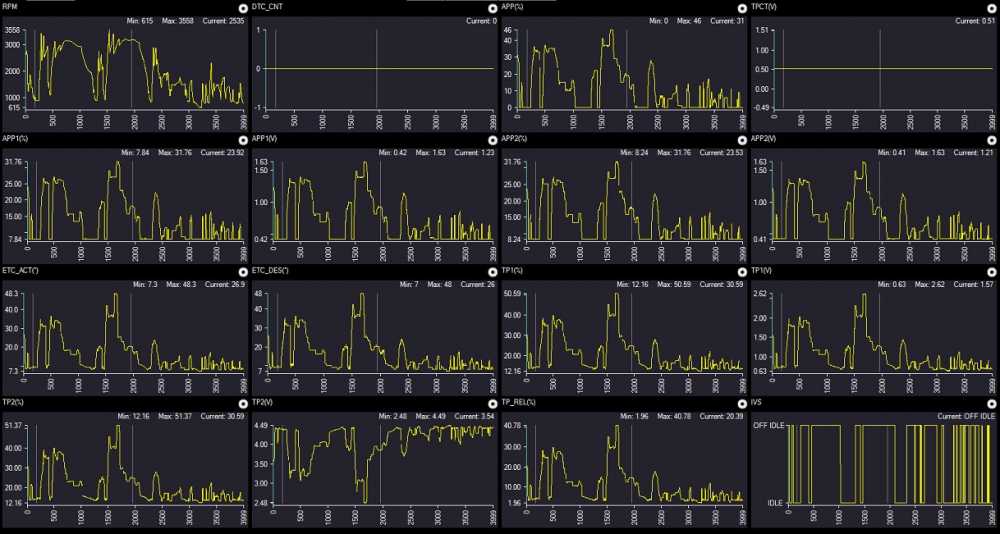

I dug up some scan data off another '05 Mazda 3 with a 2.3L (not sure if it's a VIN 3) that had a dirty throttle body. I didn't look at the APP sensor directly, but I did end up with some decent captures of scan data at idle and on a test drive. It's somewhat confusing, since the data shows an APP1 voltage, but your scope testing shows that it's NOT a potentiometer signal... Maybe an interpreted value? Anyway, the 8% at idle figure from the Troubleshooter holds up:

www.scanshare.io/share/dKswIboQmkW-wRdKxESnnA

www.scanshare.io/share/5iXHgKNHq0ut-JBkq5RXZQ

To view the ScanShare PIDs, just hit "View PIDs" on the upper toolbar.

If possible, compare this data to what you see on your Encore, see if there are any glaring differences. The IVS PID would be especially interesting. I believe it stands for Idle Validation Switch, and I think it's a calculated PID based on other inputs, not an physical switch.

Sorry it took us so long to get back to you, hoping this helps! Let us know how the KOEO throttle test and the scan data looks, and we can go from there.

Please Log in or Create an account to join the conversation.

- jcascel1

-

Topic Author

- Offline

- Junior Member

-

- DIY'er not a Pro

- Posts: 38

- Thank you received: 7

Happy Holidays to you and yours! Thanks for the response, given the holidays, I’m happy to hear from someone this soon. Yes, if for no other reason than the moral support this sure helps!

“I see that you've already tried swapping the throttle body from the 2.3L onto the 2.5L intake manifold, good move!”

The 2.3 TB has been on the entire time. I’ve never used the 2.5 TB. I did swap the 2.3 since I had a spare. No change in throttle response however.

“I'd be interested to know how the throttle butterfly itself behaves while stepping on the APP, key on engine off. If the same hesitation can be observed in the butterfly movement, then I'd say we stay with an electronic throttle issue, and move away from other inputs. If the butterfly responds normally with the engine off, but misbehaves with the engine running, then let's go towards another input.”

KOEO, the throttle butterfly responds to the APP perfectly. Even the slightest application of APP moves the butterfly. Fully closed to WOT looks good.

“I'm looking at the Troubleshooter, and this APP sensor is weird APP1 really IS a duty cycle signal, while APP2 is a conventional potentiometer. WTF Mazda? From the Troubleshooter:

KOEO, with throttle fully closed

APP #1 Duty should be 8%

APP #2 voltage should be 1.0 VDC”

Recalling my checks with the Vantage at the APP, I saw:

APP1 throttle closed = ~0%

APP2 throttle closed = ~0vdc

APP1 WOT = ~100%

APP2 WOT = ~4.5vdc

During this test, pressing down on the APP shows the voltage at APP1 increasing steadily with APP2 showing 0% until the APP1 voltage hits .8v at which point APP2 jumps to 50% and then they climb together to ~100%. Slowly closing the throttle shows the voltage slowly decreasing but the APP2 % remains high at ~95% till the magic .8v point and then % drops off to zero. However, this is not what is seen KOEO when looking at the TB butterfly! There is no dead spot and butterfly movement is right on and linear with pedal position.

I have swapped the APP and performance is the same. I’m not sure what the SO troubleshooter is getting at but I’m not trusting it based on what I’ve seen so far.

“If possible, compare this data to what you see on your Encore, see if there are any glaring differences. The IVS PID would be especially interesting. I believe it stands for Idle Validation Switch, and I think it's a calculated PID based on other inputs, not an physical switch”

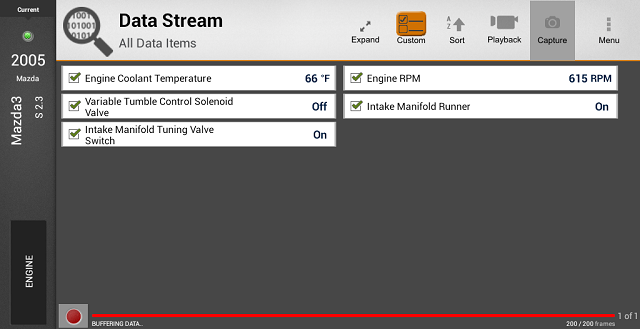

I didn’t see any major differences, EXCEPT with the IVS. Monitoring the IVS, (Idle Valid Switch) engine at idle, the PID shows OFF. The slightest touch of the gas pedal and the switch toggles to ON. Release the pedal and it goes OFF again. This is totally repeatable. In the photo below, the IVS PID is missing however my foot is off the gas and it shows as being OFF.

Disregard the earlier coil image. Clearly I obtained it incorrectly. Sorry.

Thanks,

John

Please Log in or Create an account to join the conversation.

- jcascel1

-

Topic Author

- Offline

- Junior Member

-

- DIY'er not a Pro

- Posts: 38

- Thank you received: 7

I'm apologizing in advance for my rather scatterbrained posts. Been at this 2 weeks now and it's becoming a bit of a jumble at times.

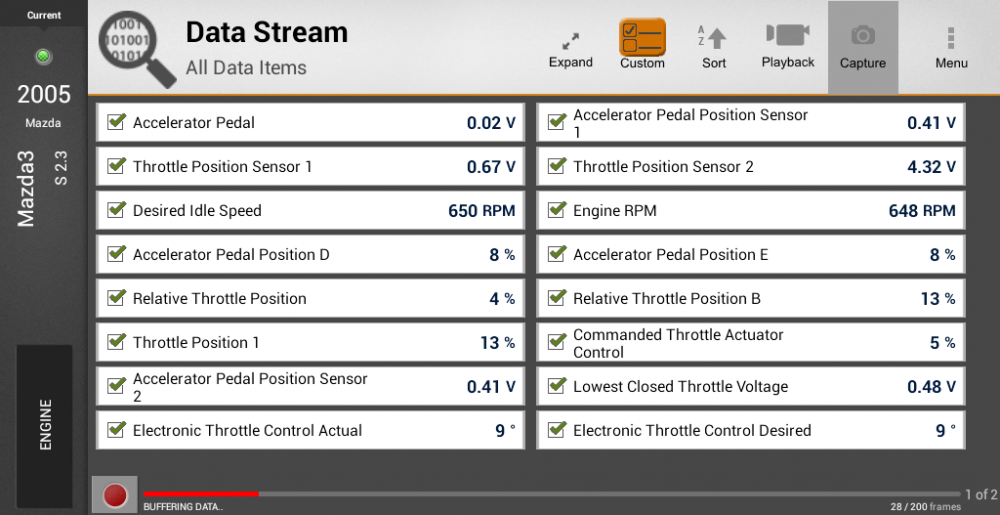

This was the data that I gathered when I discovered that at .8vdc the duty cycle jumps from 0% to ~50%.

KOEO. Measured at the APP.

Throttle Closed:

APP1 - Should be 8% Actual 0.0%

APP2 - Should be 1.0vdc Actual .31vdc

Throttle Open:

APP1 - Should be ~66.5% Actual 99.7%

APP2 - Should be 3.3vdc Actual 1.93vdc

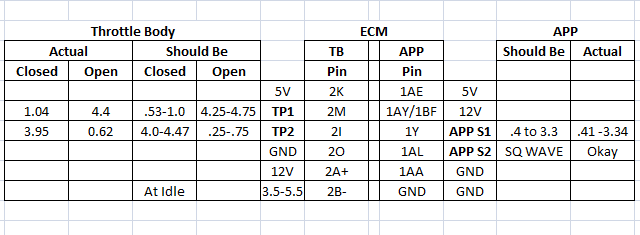

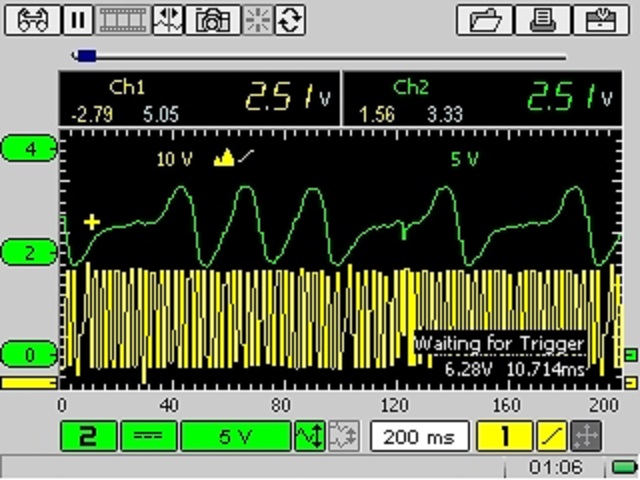

Below are my TB and APP checks at the ECM. 5 & 12vdc were good. APP square wave was present, levels good, and no dropouts detected.

Thanks,

John

Please Log in or Create an account to join the conversation.

- jcascel1

-

Topic Author

- Offline

- Junior Member

-

- DIY'er not a Pro

- Posts: 38

- Thank you received: 7

During my troubleshooting I saw that Mazda employed an Electronic Throttle Control relay. Per the FSM control system guide:

At the ECM:

Pin 1AY should have B+ with key off. However, it measures 0v. I verified this at the relay terminal.

Pin 1BF should have B+ with key on. This measures okay with battery voltage. I also verified this at the relay terminal.

At the ETC relay:

Load side has B+ on one terminal at all times.

Control side has B+ with the key on only.

I don't have the experience or circuit design knowledge to know the exact role of this relay in the circuit. So, I have not been able to understand the impact of the missing B+ at 1AY with the key off.

Thanks,

John

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6090

- Thank you received: 1538

jcascel1 wrote: Tyler,

During my troubleshooting I saw that Mazda employed an Electronic Throttle Control relay. Per the FSM control system guide:

At the ECM:

Pin 1AY should have B+ with key off. However, it measures 0v. I verified this at the relay terminal.

Pin 1BF should have B+ with key on. This measures okay with battery voltage. I also verified this at the relay terminal.

At the ETC relay:

Load side has B+ on one terminal at all times.

Control side has B+ with the key on only.

I don't have the experience or circuit design knowledge to know the exact role of this relay in the circuit. So, I have not been able to understand the impact of the missing B+ at 1AY with the key off.

From what I can tell, it seems like you did a great job testing this relay circuit!

Really, seeing 12V at pin 1BF alone tells you that the relay circuit is working. Seeing the throttle blade open and close fully backs this up, too. What I don't understand is why they told you to check for 12V at pin 1AY with the key OFF :blink: The power for the control side of the relay comes from a fuse fed by the Main Relay, so there's no reason to expect 12V at that pin with the key off... Confusing flow chart is confusing

Whatever, I'm happy with the results you posted. My understanding here is that the PCM is controlling the power feed into the PCM, that ends up going back out of the PCM to the throttle actuator. Perhaps there are times that the PCM will want to shut off power to the throttle for safety reasons?

During this test, pressing down on the APP shows the voltage at APP1 increasing steadily with APP2 showing 0% until the APP1 voltage hits .8v at which point APP2 jumps to 50% and then they climb together to ~100%. Slowly closing the throttle shows the voltage slowly decreasing but the APP2 % remains high at ~95% till the magic .8v point and then % drops off to zero. However, this is not what is seen KOEO when looking at the TB butterfly! There is no dead spot and butterfly movement is right on and linear with pedal position.

Good stuff right here. This by itself pretty much clears the APP/TAC system for me. There's DEFINITELY more to this APP signal than I understand, but I really don't believe that the throttle would work this well if there was an input problem. The behavior of the IVS data PID backs this up, too.

I guess my last thought on this would be if the throttle continues to play nice during that first 1/3 of APP travel, during the lack of engine response, with the engine running this time. If the throttle works well KOEO, but not KOER, then we can figure out what changes in between to cause the problem.

If the throttle still works corrected KOER, then I'm kinda wondering about some kind of engine breathing problem? We might start with a simple vacuum gauge reading if we go down that path. I see that the 2.5L intake is installed - there's no kind of manifold runner actuator, swirl control, or anything like that? I don't see it on the 2011 Fusion diagram, but that doesn't mean it isn't there.

No worries about being scatterbrained over this one, that's how troubleshooting goes sometimes! :lol:

Please Log in or Create an account to join the conversation.

- jcascel1

-

Topic Author

- Offline

- Junior Member

-

- DIY'er not a Pro

- Posts: 38

- Thank you received: 7

What I don't understand is why they told you to check for 12V at pin 1AY with the key OFF

I can't tell you how glad I am to hear you say that. I thought I was going crazy as I tried to work that one out in my head.

Took a junk yard APP apart just to verify if it has a switch internal or external. The answer is no switches of any kind that I can see inside or out.

Thanks! I'll get to work on the other things tomorrow.

Thanks,

John

Please Log in or Create an account to join the conversation.

- jcascel1

-

Topic Author

- Offline

- Junior Member

-

- DIY'er not a Pro

- Posts: 38

- Thank you received: 7

“If the throttle still works corrected KOER, then I'm kinda wondering about some kind of engine breathing problem? We might start with a simple vacuum gauge reading if we go down that path.”

Yes, the throttle seems to work properly KOER. It was a challenge, but I was able to actually film the throttle in action. It’s definitely responding to even the slightest inputs and to wider throttle blips.

First thing I did when this problem started was to look for intake and exhaust restrictions. I did a visual on the intake, disconnected airbox cover from the filter, but no change. I disconnected the new cat from the rest of the exhaust and no change. I never took the cat completely out of the exhaust stream though as it is part of the exhaust manifold.

However, the exhaust sounds funny to me and it’s right where the cat is. It’s kind of whistling and sounds like a leak but there is no leak. Not jumping to conclusions but from the start that area got my attention. Could my brand new cat be blocked or plugged? Though unlikely, still possible. Working on an adapter bung for a backpressure test just to rule it out.

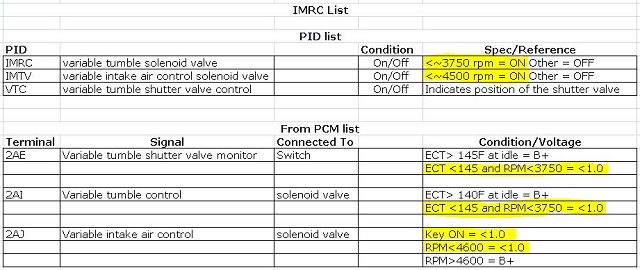

“I see that the 2.5L intake is installed - there's no kind of manifold runner actuator, swirl control, or anything like that? I don't see it on the 2011 Fusion diagram, but that doesn't mean it isn't there.”

No IMRC’s or gadgets on the 2.5L intake. The 2.3L had 2 IMRC’s; Variable Tumble and Variable Intake Air (two solenoids/two actuators. One actuator has a position switch (variable tumble shutter valve switch.) Per other 2.5L swappers, the 2.3L solenoids are still connected to the harness. The one actuator that has a switch on it is also connected to both the harness and a vacuum supply (actuator arm moves freely so ECM think it’s working.) By doing this, there are no related CEL’s.

During startup, the connected actuator retracts under vacuum. As engine warms I see that the arm moves to the released position. Status PID changes accordingly.

Terminology is confusing on the PIDs and scan tool descriptions. Per the list below, at warmup, actuator position should change. ON during warm up and low RPM and then OFF after temp goes above 145F. Have not checked signals at ECM yet. The tuning valve switch PID does not change. Don’t know why right now. Either way, there isn't anything in the manifold to cause problems! Plus, FWIW, other 2.5L swappers report no issues with this setup.

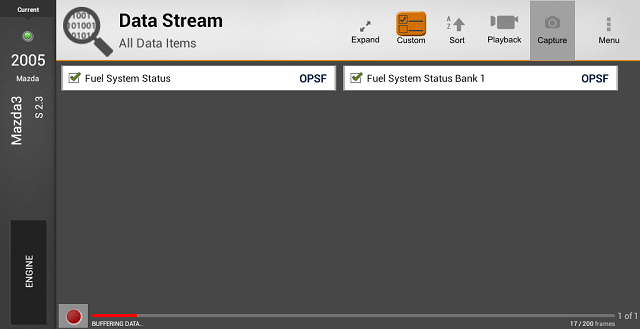

As I was playing around today, I saw that the fuel system status showed OPSF with engine fully warmed up. Any idea what that stands for? Open System Fault maybe?

Picking up a vacuum gage tomorrow in case we decide to look into it. Also, working on a video for you to watch so you can see/hear this thing for yourself. Who knows, it might help. lol Thanks!

Thanks,

John

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6090

- Thank you received: 1538

jcascel1 wrote: Yes, the throttle seems to work properly KOER. It was a challenge, but I was able to actually film the throttle in action. It’s definitely responding to even the slightest inputs and to wider throttle blips.

OK, sounds good! Thanks for entertaining this line of questioning, sir. I know that rigging the engine to run without the intake tubing probably sucked.

First thing I did when this problem started was to look for intake and exhaust restrictions. I did a visual on the intake, disconnected airbox cover from the filter, but no change. I disconnected the new cat from the rest of the exhaust and no change. I never took the cat completely out of the exhaust stream though as it is part of the exhaust manifold.

However, the exhaust sounds funny to me and it’s right where the cat is. It’s kind of whistling and sounds like a leak but there is no leak. Not jumping to conclusions but from the start that area got my attention. Could my brand new cat be blocked or plugged? Though unlikely, still possible. Working on an adapter bung for a backpressure test just to rule it out.

I guess it's possible the new cat is plugged?

A quick and dirty test you could try is just taking the upstream O2 out and rechecking for throttle response. If it's improved, then we can chase the exhaust. I see the 2.5L has an EGR valve, how tough is it to take off? If it's cake, then you can connect the vacuum gauge to the exhaust port where the valve mounts up for a quick backpressure reading. This video shows the idea. It's a different EGR design, but the same basic concept of using a remote exhaust port to measure backpressure.

No IMRC’s or gadgets on the 2.5L intake. The 2.3L had 2 IMRC’s; Variable Tumble and Variable Intake Air (two solenoids/two actuators. One actuator has a position switch (variable tumble shutter valve switch.) Per other 2.5L swappers, the 2.3L solenoids are still connected to the harness. The one actuator that has a switch on it is also connected to both the harness and a vacuum supply (actuator arm moves freely so ECM think it’s working.) By doing this, there are no related CEL’s.

Clever! OK thanks for answering this one. I knew that Mazda loved their intake tuning valves, but wasn't sure if the 2.5L had anything similar.

As I was playing around today, I saw that the fuel system status showed OPSF with engine fully warmed up. Any idea what that stands for? Open System Fault maybe?

I've never seen that PID before, but that sounds like a good guess to me! Unfortunately, all the Mazda 3 captures I have don't show loop status

Picking up a vacuum gage tomorrow in case we decide to look into it.

I'm thinking this is a good next step. To start with, lets get a vacuum reading at idle and at 2500 steady. We may do more gauge testing later, but this'll get us started. Thanks, sir!

Please Log in or Create an account to join the conversation.

- jcascel1

-

Topic Author

- Offline

- Junior Member

-

- DIY'er not a Pro

- Posts: 38

- Thank you received: 7

Disregard that. Looks like that was due to my attempts to run the engine with the intake snorkel mostly disconnected to check TB butterfly response.I've never seen that PID before, but that sounds like a good guess to me!

With the pre-cat O2 removed and no gage, performance does not change. (I could see the glowing red cat honeycomb through the O2 port. Pretty cool.)A quick and dirty test you could try is just taking the upstream O2 out and rechecking for throttle response. If it's improved, then we can chase the exhaust.

With the gage in place of the O2, at startup, the needle is right around the 1psi mark. Needle is shaky. High revs or a trip to WOT gets the pressure to around 3.5 or 4psi. Off the gas and it drops back down to around 1psi.I guess it's possible the new cat is plugged?

Ugly, very very ugly. First of all it is nearly impossible to modulate the throttle and rev this engine let alone hold the rpms steady. But I did my best with a couple of runs at around 2k rpms and then a couple of WOT’s. During the elevated rpm testing, the damn needle was just all over the place but below is my interpretation. I made a video of the testing so I could refer back to it as I’m working alone. Will post at some point but it’s painful to watch. lolTo start with, lets get a vacuum reading at idle and at 2500 steady. We may do more gauge testing later, but this'll get us started.

Vacuum gage connected to purge valve port at the intake manifold. (End of purge valve hose left open. Shouldn't matter I think.)

Idle: ~9”Hg with a shaky needle.

Raised RPM of ~2000: Between 10” and 15”Hg with steady needle.

Trips to WOT: The highest reading recorded was 21”Hg.

Notes:

Opening the throttle does reliably draw the vacuum down to 0”Hg.

After extensive revving and then back to idle, the vacuum drops down a bit to around ~7”Hg.

After extensive revving, recovery time back to the idle inHg is fairly fast.

Note on Fuel Pressure observed during testing:

Fuel pressure at idle is in spec but needle is very shaky. At high revs the pressure stays in spec and the needle is stable. Prime is good and hold is good. Fuel pump is a new Carter installed by me a couple of months ago.

I’m utterly mystified and frustrated by all of this info right now. The elevated exhaust pressure may be a problem but performance does not change with O2 removed. The low vacuum, as far as I know from reading, indicates either a vacuum leak at the intake or timing issues. I don’t hear any vacuum leaks and did check several weeks ago. The timing was set by someone who has set timing on the keyless cranked 2.3L’s before and we used the appropriate timing tools. After all of this testing – no check engine light.

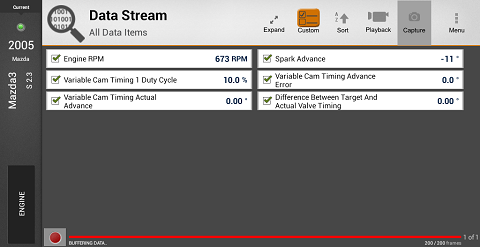

I’ll double down on vacuum leak testing I guess. But then, LTFT shows at -20 so why bother! lol Timing, which shows fine via the Encore at around 9 degrees at idle, remains a question I guess. From the Encore's PID's, at idle and elevated rpm’s there is no variance (error) shown for cam timing either.

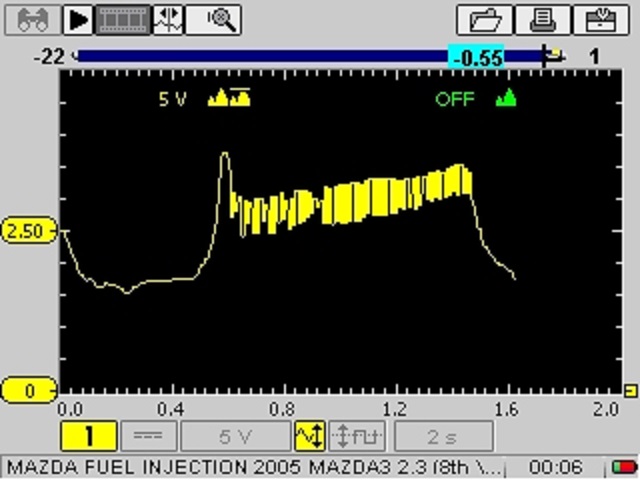

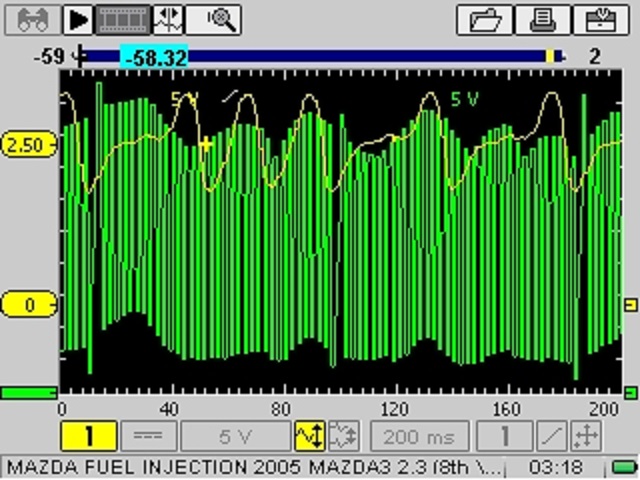

Below, a rather depressing Vantage capture of the MAF during a WOT blip:

Thanks,

John

Please Log in or Create an account to join the conversation.

- jcascel1

-

Topic Author

- Offline

- Junior Member

-

- DIY'er not a Pro

- Posts: 38

- Thank you received: 7

Thanks,

John

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6090

- Thank you received: 1538

jcascel1 wrote: With the pre-cat O2 removed and no gage, performance does not change. (I could see the glowing red cat honeycomb through the O2 port. Pretty cool.)

With the gage in place of the O2, at startup, the needle is right around the 1psi mark. Needle is shaky. High revs or a trip to WOT gets the pressure to around 3.5 or 4psi. Off the gas and it drops back down to around 1psi.

Hmmmmm, the readings at higher engine speed are technically a problem, but I don't think it's a smoking gun for an exhaust restriction. Paul usually quotes 2 PSI max at a steady 2500 RPM, but it sounds like holding a steady engine speed is very difficult on this one.

The glowing honeycomb, though, that IS a problem. :ohmy: Your cat may not be plugged now, but it will be if we keep this up too long... The glowing also backs up the rich fuel trims.

Idle: ~9”Hg with a shaky needle.

Raised RPM of ~2000: Between 10” and 15”Hg with steady needle.

Trips to WOT: The highest reading recorded was 21”Hg.

Notes:

Opening the throttle does reliably draw the vacuum down to 0”Hg.

After extensive revving and then back to idle, the vacuum drops down a bit to around ~7”Hg.

After extensive revving, recovery time back to the idle inHg is fairly fast.

Nice detail here, sir! Love it. I was expecting low idle vacuum, but not 9" :lol: This thing really isn't breathing right, somehow. The gauge going to zero when opening the throttle tends to rule out an intake problem, and the gauge recovering back to vacuum quickly tends to rule out exhaust restriction.

The elevated exhaust pressure may be a problem but performance does not change with O2 removed.

Totally agree.

The low vacuum, as far as I know from reading, indicates either a vacuum leak at the intake or timing issues. I don’t hear any vacuum leaks and did check several weeks ago. The timing was set by someone who has set timing on the keyless cranked 2.3L’s before and we used the appropriate timing tools. After all of this testing – no check engine light.

begin:rambling

I was going to ask you about timing, but then I saw that the correct tools were used! I gotta say, I've heard of other Ford engines of this design with timing issues, and they also had poor idle and glowing catalyst symptoms

The OCV caught my eye for a moment, but then I remembered that the intake cam is monitored, and would've flagged a P0340 if it were stuck on/open. Your screenshots of the cam timing data look good, BTW

I'm still wondering about the EGR valve being stuck open, as this would definitely cause idle problems, hesitation, and skewed fuel trims. The wiring diagram does not show any kind of potentiometer inside the valve, so there's no way for the PCM to verify valve position compared to command.

How much work is it to get to the EGR? If it's easy, I say take it off and have a look, and possibly swap in the 2.3L valve if it'll fit. If it's work, then we can do some bypass testing to open the valve manually, and check for response.

end:rambling :lol:

Also, I love that MAF capture! You can totally see how the engine is struggling to gain speed the entire time. All the noise in the trace after the throttle first opened suggests that the airflow is 'stacking up' in the intake, and not flowing smoothly as it should. I mean, we kinda knew that already, but it's still a cool visual.

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4992

- Thank you received: 1115

I like the swap idea, I'd be tempted to do the same thing in your situation. I've got a thing for unorthodox Ford projects

That's quite a jump up as far as year range, '05-'11! I keep envisioning some kind scenario where maybe the manifold bolts to the head but partially blocks an exhaust port or maybe leaves an integrated EGR port wide open. (purely speculation, I don't know what the head looks like)

I've been thinking about the 2.5l injectors also. Would they contribute to a rich condition beyond the PCM's ability to control? While technically I assume they must be rated at a higher flow rate, would they necessarily realize their full potential under the 2.3l engine managment system, even with the 2.5l MAF installed?

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- jcascel1

-

Topic Author

- Offline

- Junior Member

-

- DIY'er not a Pro

- Posts: 38

- Thank you received: 7

I see that you have the intake from the 2.5 on the engine. How about the exhaust manifold?

No, I'm using the 2.3L exhaust. I've been told by other swappers that the only difference exists in the size of the intake ports on the 2.5 head, hence my use of the 2.5L intake mani and 2.3L exhaust. Other swappers use an adapter between the 2.5 head and 2.3 intake without problems. I've never heard of any exhaust port differences and swappers report using the 2.3 exhaust without problems. I've not verified differences myself, so there I am neglectful. The EGR port is integrated into cylinder fours exhaust port. The exhaust gasket and exhaust manifold were a proper fit. Running with the upstream O2 removed did not improve performance. Todays EGR experiment proved that EGR is working properly (see newest post to Tyler.)I keep envisioning some kind scenario where maybe the manifold bolts to the head but partially blocks an exhaust port or maybe leaves an integrated EGR port wide open. (purely speculation, I don't know what the head looks like)

Just took some measurements. 2.3L exhaust ports measure ~37mm. 2.5L measure ~40mm. I put the old 2.5L gasket and manifold on the 2.3L and everything lined up just right. Including the EGR port at number 4 cyl.

Realizing their full potential, no, probably not without a tune of some sort. The Mazda FSM states that the range for the LTFT is +/-14% and STFT is +/-25%. My LTFT is -20 and STFT is ~0. So, maybe you are right, the 2.3 PCM can't handle it. Another swap back to the 2.3L injectors is warranted. Previous swap back to them was uneventful. Lately, I've noticed that in order for me to get the thing started if it stalls, that I have to do it by using the clear flood mode. This is a new development however as previously I could just fire it up.I've been thinking about the 2.5l injectors also. Would they contribute to a rich condition beyond the PCM's ability to control? While technically I assume they must be rated at a higher flow rate, would they necessarily realize their full potential under the 2.3l engine managment system, even with the 2.5l MAF installed?

However, Would injectors and challenges with fuel trims contribute to the ultra low engine vacuum readings of <10inHg?

One thing nobody has commented on is in my very first post. The engine load at idle shows to be ~35%! Throttle blips move it to almost 50%. Isn't this noteworthy in some way? Sensors are working properly. Mazda FSM states that at idle it should be ~18%.

Thanks,

John

Please Log in or Create an account to join the conversation.

- jcascel1

-

Topic Author

- Offline

- Junior Member

-

- DIY'er not a Pro

- Posts: 38

- Thank you received: 7

I looked over the timing again today. I did not put the pin through the block to check crank position since I just wasn’t in the mood to pull the axle. Granted that is not satisfactory but that said, everything looked good.I was going to ask you about timing, but then I saw that the correct tools were used! I gotta say, I've heard of other Ford engines of this design with timing issues, and they also had poor idle and glowing catalyst symptoms

The trouble is that, on this design, only the intake camshaft is monitored by the ECM. It's possible that the exhaust cam is out of time, and the PCM won't know it. Unlikely, since it sounds like the timing was set up correctly, but possible.

Pulley alignment bolt through the pulley and into the timing cover.

9th tooth of the crank timing wheel aligned with center of CKP sensor.

Intake/Exhaust lobes near gears pointing towards each other.

Timing tool in place at the end of both cams.

VVT notches aligned even after multiple engine rotations.

Chain tension good but there was one spot where it was just a tad looser.

There is one thing I need to verify regarding setting the timing. My guess is that only a Mazda/Ford tech can answer the question. It has to do with the crankshaft position relative to the timing pin that goes through the block. One side of the cylinder 1 crank weight has a depression in it and the other is flat. I can’t recall if one side is BDC and the other is TDC (does that even make sense?) We used the depression side. Guessing though that the thing just flat out wouldn’t run if it was indeed BDC. Probably thinking wrong but I sure would like to hear someone who knows for sure verify it for my own peace of mind!

How sensitive are these things to timing? Who knows, but the keyless crank sure doesn’t help to inspire any confidence. What a despicable design.

I did a sloppy Vantage grade cam/crank correlation and compared it to my other 2.3. Looked good but I don’t have Pico grade tools with which to compare them. First pic is known good and second is my 2.5.

Very easy. Just took the cover (solenoid) off and pressed on the valve by hand. Ran poorly like always with the cover off. Pressing down (opening) on the valve killed the engine instantly. Even the slightest opening of the valve had an effect. Valve moved freely.I'm still wondering about the EGR valve being stuck open, as this would definitely cause idle problems, hesitation, and skewed fuel trims. How much work is it to get to the EGR?

I like to call it, Volumetric Deficiency! Would Paul be proud of me? Probably not! LolAlso, I love that MAF capture!

Timing,/intake/exhaust: Thoughts...

Timing according to PID’s, cam/crank correlation, and visual inspection looks good (pending crank weight verification.)

Intake could use more scrutiny for a gigantic vacuum leak that I somehow can’t hear or see! Finally, there is the PCV valve but boy that is a long shot especially since this engine is in such good shape. Reading indicated that very erratic vacuum gage readings could be PCV related. A stretch though.

Brand new cat and exhaust remains questionable but not a show stopper.

So, what’s next? Tomorrow I guess I’ll pull the intake off and just have a look. Also need to go back and revisit using the 2.3 injectors per my comments with Noah.

Thanks,

John

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6090

- Thank you received: 1538

jcascel1 wrote: So, what’s next?

Good question! :lol: Nah, we've still got good direction. This problem just won't go down without a fight

I looked over the timing again today. I did not put the pin through the block to check crank position since I just wasn’t in the mood to pull the axle. Granted that is not satisfactory but that said, everything looked good.

Pulley alignment bolt through the pulley and into the timing cover.

9th tooth of the crank timing wheel aligned with center of CKP sensor.

Intake/Exhaust lobes near gears pointing towards each other.

Timing tool in place at the end of both cams.

VVT notches aligned even after multiple engine rotations.

Chain tension good but there was one spot where it was just a tad looser.

There is one thing I need to verify regarding setting the timing. My guess is that only a Mazda/Ford tech can answer the question. It has to do with the crankshaft position relative to the timing pin that goes through the block. One side of the cylinder 1 crank weight has a depression in it and the other is flat. I can’t recall if one side is BDC and the other is TDC (does that even make sense?) We used the depression side. Guessing though that the thing just flat out wouldn’t run if it was indeed BDC. Probably thinking wrong but I sure would like to hear someone who knows for sure verify it for my own peace of mind!

How sensitive are these things to timing? Who knows, but the keyless crank sure doesn’t help to inspire any confidence. What a despicable design.

TRUTH. This setup is just asking for problems. I do know that these are very sensitive to timing issues, but I don't see any indication of a problem so far. Everything you've noted looks good.

I don't know for certain about the timing pin in relation to the crank weight, I can do some research on that tomorrow. I suppose, if you wanted to, you could use a long screwdriver/extention/whatever in the #1 plug hole to verify where the piston is when the marks line up?

I did a sloppy Vantage grade cam/crank correlation and compared it to my other 2.3. Looked good but I don’t have Pico grade tools with which to compare them. First pic is known good and second is my 2.5.

No worries about the Pico, these are good captures. It looks to me like the lowest valley of an individual CMP pulse lines up with the very last tooth on the CKP before the sync notch in both captures. I compared this to a known good on iATN, and it agrees with yours.

Very easy. Just took the cover (solenoid) off and pressed on the valve by hand. Ran poorly like always with the cover off. Pressing down (opening) on the valve killed the engine instantly. Even the slightest opening of the valve had an effect. Valve moved freely.

Swing and a miss for me

I like to call it, Volumetric Deficiency! Would Paul be proud of me? Probably not! Lol

:lol: :lol: :lol: :lol: I dunno if Paul would be proud, but I like it!

Timing according to PID’s, cam/crank correlation, and visual inspection looks good (pending crank weight verification.)

So, with this (horrible) timing design, it's possible to have the cams line up with each other, have the cam and crank tone wheels line up with each other, and still have the crankshaft out of time, correct? This would possibly result with the pistons being out of time with the cam events, and still not detectable by the PCM. Am I understanding this correctly? :huh:

One thing nobody has commented on is in my very first post. The engine load at idle shows to be ~35%! Throttle blips move it to almost 50%. Isn't this noteworthy in some way? Sensors are working properly. Mazda FSM states that at idle it should be ~18%.

Wow, 18%? That's way lower than I usually see on import engines. Anyway, I didn't initially speculate on that since I regularly see idle Engine Load above 30% on known good vehicles. This seems counterintuitive, but it's how they run :blink:

But, I think the MAP sensor may possibly explain the 35% reading? This system has both a MAP and MAF sensor, and we know already that the engine runs the same way without the MAF. With the engine showing 9" inHg at idle, the MAP is reading the same, and relaying this to the PCM. Lower vacuum means more load, which is probably driving the Engine Load reading up. This may also account for the skewed MAF g/s reading, if that PID is calculated between the MAF and MAP readings.

I was digging some more, and I see that this thing has a MAP and a BARO sensor? Where's the BARO sensor, physically? I'm guessing the MAP sensors is on the intake, correct me if I'm wrong. Also, I see that the MAP sensor has four wires? :blink: Strange and more strange, Mazda.

Just for curiosity, I dug up some data off the same Mazda 3 I posted earlier. Indeed, the idle Engine Load is lower:

What I wish I had was some captures with the BARO PID in them.

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6090

- Thank you received: 1538

foxed.ca/rx7manual/manuals/NC%20Miata-MX...ming%20Procedure.pdf

Does this seem correct? The PDF makes it sound like you can install the timing pin whenever you like, and just spin the crank until the counterweight hits the pin. This may not be true with the 2.5.

Please Log in or Create an account to join the conversation.

- jcascel1

-

Topic Author

- Offline

- Junior Member

-

- DIY'er not a Pro

- Posts: 38

- Thank you received: 7

Yes, correct. That's how it was done. The 2.5 has a timing pin sized shallow recess on one side of the crank weight. Perhaps that indicates TDC which makes sense. I guess one timing related mark on the engine isn't too much to ask for. Thanks Ford!Did some more digging, found this Mazda procedure for checking timing on several of their four cylinder engines. Does this seem correct?

Good question! Nah, we've still got good direction. This problem just won't go down without a fight.

Yes, I think you’re right Tyler. This certainly wasn’t the plan. I’m slowly starting to feel defeated. See my injector comments below for a big reason why.TRUTH. This setup is just asking for problems. I do know that these are very sensitive to timing issues, but I don't see any indication of a problem so far. Everything you've noted looks good.

Yup. Will do.I don't know for certain about the timing pin in relation to the crank weight, I can do some research on that tomorrow. I suppose, if you wanted to, you could use a long screwdriver/extention/whatever in the #1 plug hole to verify where the piston is when the marks line up?

Yes, unbelievably enough, that seems to be correct. I’m a diyer so don’t know 100% about PCM detecting that relationship.So, with this (horrible) timing design, it's possible to have the cams line up with each other, have the cam and crank tone wheels line up with each other, and still have the crankshaft out of time, correct? This would possibly result with the pistons being out of time with the cam events, and still not detectable by the PCM. Am I understanding this correctly?

Regarding timing. The Fusion engine intake cam has a tone ring (timing gear) on the intake cam that has 6 teeth on it. The Mazda 2.3 intake cam has a tone ring that has 5 teeth on it. This was true for the 2004 and 2005 models and Mazda changed it to the 6 tooth design in 2006. So, I pulled the 5 tooth ring of f of my 2.3 intake cam and pressed it on the Fusion 2.5 intake cam. R&R was done by auto enthusiast machinist and I’m totally satisfied with the alignment/position of the ring on the 2.5 intake cam. Plus, no cam codes. Just mentioning this for full disclosure. Anyway, nothing points to a problem in this area.

But, I think the MAP sensor may possibly explain the 35% reading? This system has both a MAP and MAF sensor, and we know already that the engine runs the same way without the MAF. With the engine showing 9" inHg at idle, the MAP is reading the same, and relaying this to the PCM. Lower vacuum means more load, which is probably driving the Engine Load reading up. This may also account for the skewed MAF g/s reading, if that PID is calculated between the MAF and MAP readings.

Yes, it’s a BARO, MAP, and MAF system. Yes, four wires. BARO is external and right next to the MAF by the air box. Regarding the elevated load, I suspected MAP, MAF, BARO too. Like you, I initially suspected the MAP as the culprit for the load problem. Originally, I used the 2.3 MAP. Although it Vantage tested good, I got curious and tried the 2.5 MAP. No change. I believe that they are the same part number anyway. MAP and BARO readings generally agree from viewing PID’s.I was digging some more, and I see that this thing has a MAP and a BARO sensor? Where's the BARO sensor, physically? I'm guessing the MAP sensors is on the intake, correct me if I'm wrong. Also, I see that the MAP sensor has four wires? :blink: Strange and more strange, Mazda.

Connector looks good. No other wiring changes. Again, BARO PID looks normal. Generally matches MAP reading. I have a spare BARO sensor. Have not tried to swap it out as I saw no reason to.Just for curiosity, I dug up some data off the same Mazda 3 I posted earlier. Indeed, the idle Engine Load is lower: What I wish I had was some captures with the BARO PID in them.

No offense meant, but I'm wondering if there's a way for the BARO to be hooked up incorrectly, confusing the PCM.

Progress! Well, sort of. I put the 2.3 injectors in today and all went well in that the trims looked perfect! In fact the LT/ST seemed to be countering each other to correct! Throttle response was somewhat better but there was still that damn sound giving the impression that the engine just isn’t breathing right. Then, after only around 3 minutes of throttle response testing later, the cat started glowing red through the heat shield! So, I had to shut down. That $260 cat is done no doubt. I already tossed my old 2.3 cat/manifold.

Why the improvement after injector swap now and not before? Last time I put the 2.3 injectors in I believe that the plugs were fouled and that's why I really didn't seen any improvement in performance. Verifying this, right after I put the 2.3 injectors in, the situation became a crank no start till I swapped plugs. By then, I had already put the 2.5 injectors back in. At least, this is my theory. lol

Reality Check:

Damn, what a quandary I’m in! With what amounts to a melted cat and no backup, this project is on hold since I’m not starting the engine with that cat again. If it wasn't a problem before it's got to be now. Don’t really know what I’m gonna do at this point.

I can get a new cat and hope that, with the way that the 2.3 injectors significantly improved fuel trims, that the cat toasting rich condition may now be gone. That way I can continue to trouble shoot the low vacuum problem.

Or, I can take this car and all of the money and time I’ve invested in it and turn it into an epic fail learning experience, buy my kid another car, and get him back on the road. That is, once I can save up enough money to buy him another car which was what I was trying to avoid!

What a mess. The very definition of an epic fail.

I’m too frustrated and disappointed to make any kind of decision right now. Ugh.

Got to walk away from this one for a day and think....

Thanks,

John

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6090

- Thank you received: 1538

Got to walk away from this one for a day and think....

I understand, sir. Sometimes walking away and coming back is the best possible option! I've still got ideas bouncing around in my head, so I might keep posting. Please don't feel obligated to answer until you're ready to come back to this one.

The really frustrating part is that this swap is supposed to work!

Regarding timing. The Fusion engine intake cam has a tone ring (timing gear) on the intake cam that has 6 teeth on it. The Mazda 2.3 intake cam has a tone ring that has 5 teeth on it. This was true for the 2004 and 2005 models and Mazda changed it to the 6 tooth design in 2006. So, I pulled the 5 tooth ring of f of my 2.3 intake cam and pressed it on the Fusion 2.5 intake cam. R&R was done by auto enthusiast machinist and I’m totally satisfied with the alignment/position of the ring on the 2.5 intake cam. Plus, no cam codes. Just mentioning this for full disclosure. Anyway, nothing points to a problem in this area.

Ah, good to know! I think you're right, though, I see no reason to suspect a problem here. If there were, then the cam/crank correlation would be off, or the cam timing bar wouldn't have lined up. The issue with the crank being out of time is still possible, but I don't know that I want you to pull the axle without more evidence to justify it.

Yes, it’s a BARO, MAP, and MAF system. Yes, four wires. BARO is external and right next to the MAF by the air box. Regarding the elevated load, I suspected MAP, MAF, BARO too. Like you, I initially suspected the MAP as the culprit for the load problem. Originally, I used the 2.3 MAP. Although it Vantage tested good, I got curious and tried the 2.5 MAP. No change. I believe that they are the same part number anyway. MAP and BARO readings generally agree from viewing PID’s.

They agree? :blink: I need to do some research, but my understanding is that this BARO sensor should read atmospheric pressure at all times. If there's vacuum connected to the BARO sensor, then that could be part of the problem.

Progress! Well, sort of. I put the 2.3 injectors in today and all went well in that the trims looked perfect! In fact the LT/ST seemed to be countering each other to correct! Throttle response was somewhat better but there was still that damn sound giving the impression that the engine just isn’t breathing right. Then, after only around 3 minutes of throttle response testing later, the cat started glowing red through the heat shield! So, I had to shut down. That $260 cat is done no doubt. I already tossed my old 2.3 cat/manifold.

If it makes you feel better, I have seen catalysts survive stuff like this. It's life has probably been reduced, but it may not be completely useless yet.

Please Log in or Create an account to join the conversation.