Help us help you. By posting the year, make, model and engine near the beginning of your help request, followed by the symptoms (no start, high idle, misfire etc.) Along with any prevalent Diagnostic Trouble Codes, aka DTCs, other forum members will be able to help you get to a solution more quickly and easily!

2009 dodge challenger rt with 5.7 engine no crank, no start and no communication

- ChallengerDude

-

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 26

- Thank you received: 4

10 months 2 weeks ago #83782

by ChallengerDude

Replied by ChallengerDude on topic 2009 dodge challenger rt with 5.7 engine no crank, no start and no communication

Thanks for clearing that up. Just want to double check before jumping any wires.

I saw the 4v on the tp sensor wire. I also depined it and put a probe and the sensor is giving 4v. It seems that a throttle position sensor is supposed to be .7v to 4.5v. Maybe the second wire is supposed to be the inverse.

I saw the 4v on the tp sensor wire. I also depined it and put a probe and the sensor is giving 4v. It seems that a throttle position sensor is supposed to be .7v to 4.5v. Maybe the second wire is supposed to be the inverse.

Please Log in or Create an account to join the conversation.

- ChallengerDude

-

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 26

- Thank you received: 4

10 months 2 weeks ago #83783

by ChallengerDude

Replied by ChallengerDude on topic 2009 dodge challenger rt with 5.7 engine no crank, no start and no communication

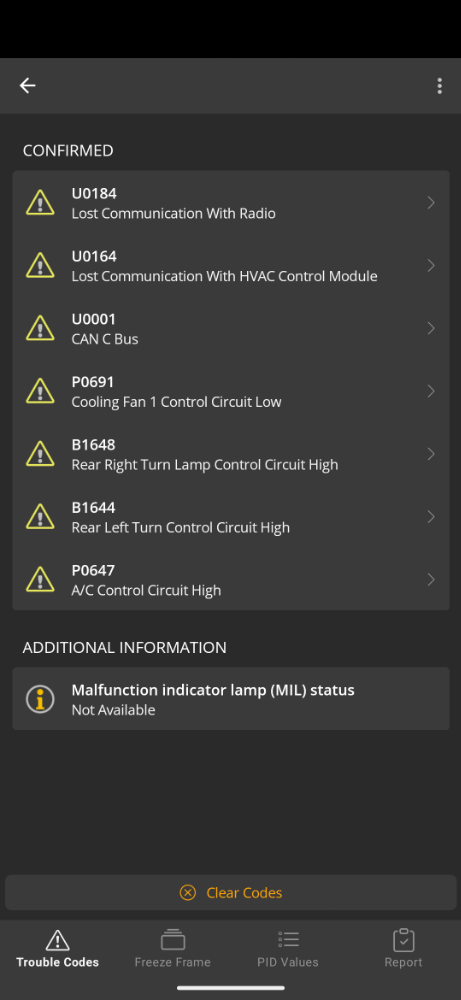

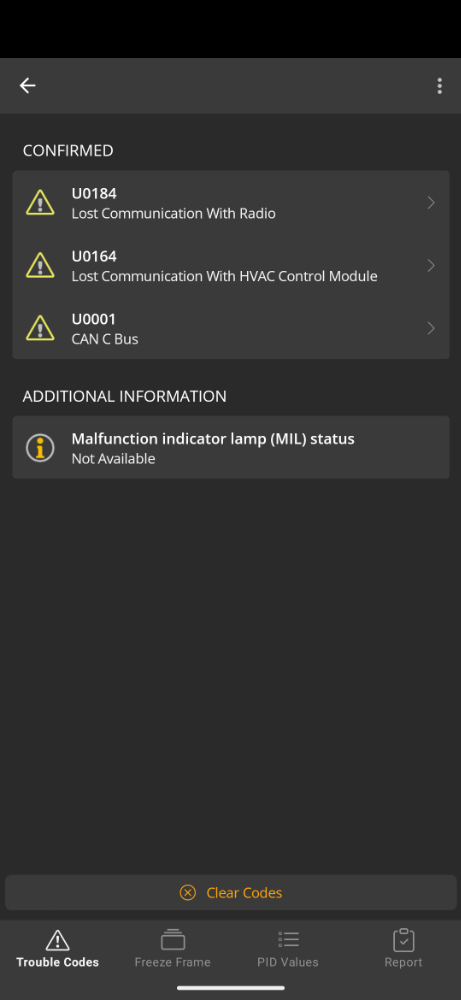

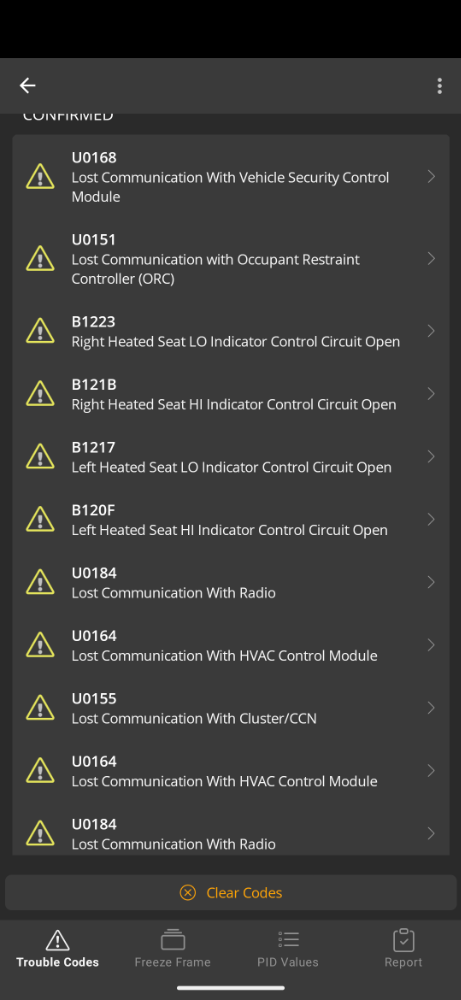

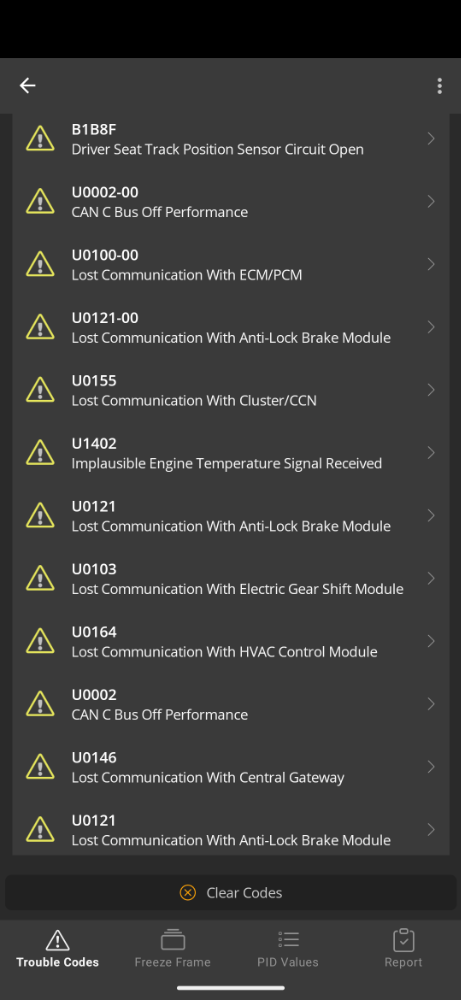

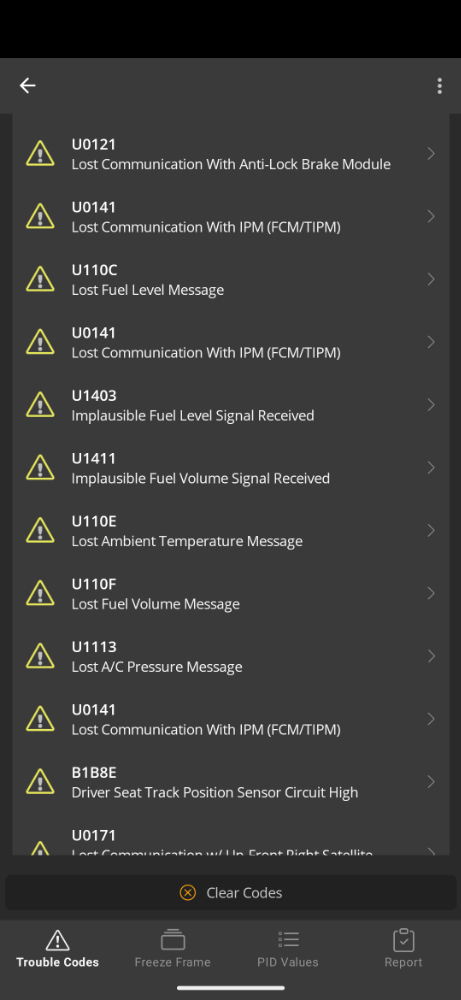

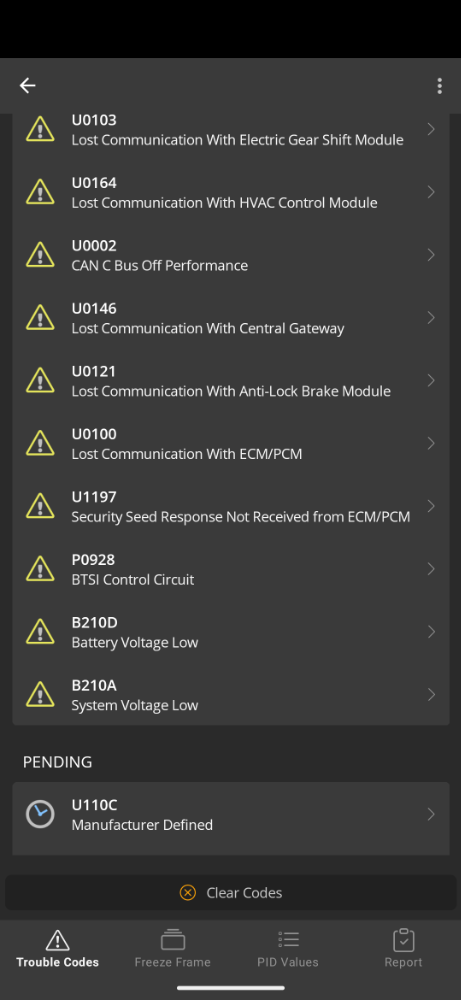

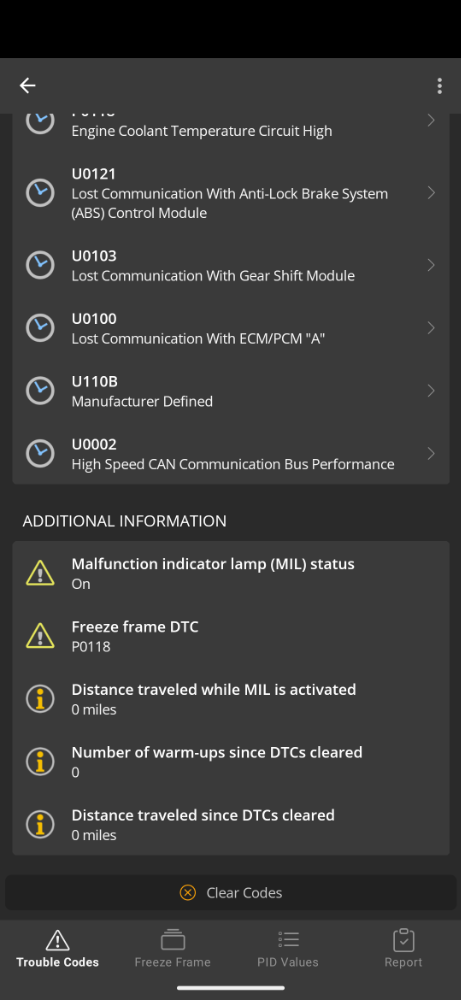

I tried plugging in the obd doggle to the can c network on the pcm side of the tipm. I was able to connect and pull come codes. Thought none for the etcm. These are all before clearing any codes so a bunch from unplugging things.

Please Log in or Create an account to join the conversation.

- Monde

-

- Offline

- Elite Member

-

Less

More

- Posts: 220

- Thank you received: 43

10 months 2 weeks ago #83784

by Monde

Assuming is never a good thing.

Replied by Monde on topic 2009 dodge challenger rt with 5.7 engine no crank, no start and no communication

ETCM: Electrronic throttle control motor? If this it what that means, it should be part of the PCM.

How is the battery? I see a low battery voltage code.

How is the battery? I see a low battery voltage code.

Assuming is never a good thing.

Please Log in or Create an account to join the conversation.

- ChallengerDude

-

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 26

- Thank you received: 4

10 months 2 weeks ago #83808

by ChallengerDude

Replied by ChallengerDude on topic 2009 dodge challenger rt with 5.7 engine no crank, no start and no communication

It's the actual throttle, motor and 2 sensors built into one assembly.

Battery is good, keep charging it while troubleshooting.

Battery is good, keep charging it while troubleshooting.

Please Log in or Create an account to join the conversation.

- Monde

-

- Offline

- Elite Member

-

Less

More

- Posts: 220

- Thank you received: 43

10 months 2 weeks ago - 10 months 2 weeks ago #83821

by Monde

Assuming is never a good thing.

Replied by Monde on topic 2009 dodge challenger rt with 5.7 engine no crank, no start and no communication

The etcm is not a module. We only have to test the ect and etcm ( TPS! and TPS2)for 5v ref. If we disconnect the ect and back probe the connector, we should get 5v letting us know that the pcm is somewhat alive and that we don't have an issue with the 5v ref (Not shorted)

Upon checking the codes you posted, I have noticed some P and B codes which is kind of confusing because there is a code for no communication with pcm

At this point, you may need to start all over. Check the whole high speed can bus for opens and shorts. If no opens and shorts are found, you may need to start disconnecting all the modules on the bus including the steering angle sensor module which appears to be on two buses.

I did some more reading about the high speed can. We need to have 2,5v and 60 ohms at any module on the high speed can. ( usually can high has 2.6 and can low, 2.4). If one resistor is in a module, you should read 120 when the module is disconnected or if there is an open in the can lines leading to the module with the resistor. If you measure 60 ohms and 2.5v at all the modules, the bus is intact. If one resistor is shorted, you will read less than 60 ohms and less than 2.5v . If both can lines are shorted together, you will have the same reading on can hi and low.

For anyone reading this post, try to apply this and see if it works. I am just trying to understand the bus.

Upon checking the codes you posted, I have noticed some P and B codes which is kind of confusing because there is a code for no communication with pcm

At this point, you may need to start all over. Check the whole high speed can bus for opens and shorts. If no opens and shorts are found, you may need to start disconnecting all the modules on the bus including the steering angle sensor module which appears to be on two buses.

I did some more reading about the high speed can. We need to have 2,5v and 60 ohms at any module on the high speed can. ( usually can high has 2.6 and can low, 2.4). If one resistor is in a module, you should read 120 when the module is disconnected or if there is an open in the can lines leading to the module with the resistor. If you measure 60 ohms and 2.5v at all the modules, the bus is intact. If one resistor is shorted, you will read less than 60 ohms and less than 2.5v . If both can lines are shorted together, you will have the same reading on can hi and low.

For anyone reading this post, try to apply this and see if it works. I am just trying to understand the bus.

Assuming is never a good thing.

Last edit: 10 months 2 weeks ago by Monde.

Please Log in or Create an account to join the conversation.

- ChallengerDude

-

Topic Author

- Offline

- Junior Member

-

Less

More

- Posts: 26

- Thank you received: 4

10 months 1 week ago - 10 months 1 week ago #84139

by ChallengerDude

Yeah, the whole assembly with the throttle, 2 motors and 2 sensors. Not sure if assembly is right phase but the sensors are built in. The 5v ref wire is 5v, once of the sensors is .7v and goes up to 4.5v when the throttle is opened. The second does the opposite starts at 4.5v and goes down to .7v as the throttle is opened.

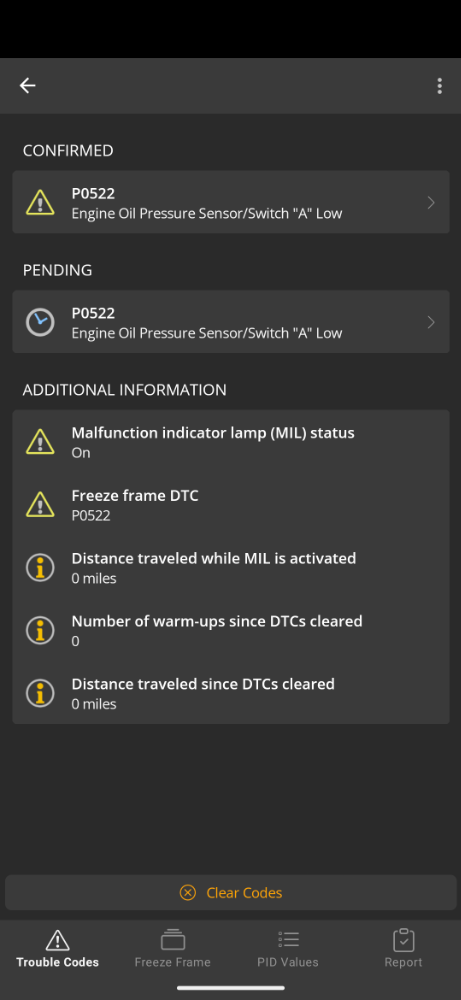

Going through wire and modules, nothing popped out. Got a rebuilt TIPM and installed it. Was able to communicate with the pcm through the dlc. The ect and cel were still on. Checked back the next day. Connected to the dlc and looked at the diagnostic codes. Went ahead and cleared them. One of the codes was for a oil pressure sensor. Went and checked the 5v, signal and ground on it. It was unplugged from previous troubleshooting. The 5v and ground tested at 5v and ground the signal wire 4.5v when unplugged to the sensor and went to 0 at the sensor. Looked back at the dash and noticed the ect light was gone. Trying starting the car and was successful. Was able to repeat the car start. The oil pressure light was still on. Thought it might be because the car was on jack stands and lifted in the front. Oil dipstick showed below the mark for oil level. Lowered the car to ground and dip stick had the oil level in between the lines. Tried starting the car. The car was able to start but still showed the oil pressure light and cel. I checked the throttle position on the scanner and when hitting the accelerator the pcm showed the change in throttle position. The ect system seems to be working.

I'm going to put the original oil pressure sensor back in and see if that clears up the oil pressure warning and cel.

Not sure why a damaged TIPM would cause the ect light. But looks like the ect system is part of the ASD circuit and if there is an issue it won't let you crank the car. The only thing that pointed to the TIPM was that you couldn't connect through it as a bridge to the can bus to read the pcm and you could read the pcm if you connected to the can bus directly without going through the TIPM.

There's still a rodent running around and in the car. Haven't found any more damaged wires after pulling most of the interior but found evidence of it's presence in the cabin, trunk, engine bay and on top of the roof.

I'd check if there still is a draw on the battery. But It's probably still there as I unplugged the tipm before and it still showed as .185A. The spec is less that .035A.

Replied by ChallengerDude on topic 2009 dodge challenger rt with 5.7 engine no crank, no start and no communication

Yeah, the whole assembly with the throttle, 2 motors and 2 sensors. Not sure if assembly is right phase but the sensors are built in. The 5v ref wire is 5v, once of the sensors is .7v and goes up to 4.5v when the throttle is opened. The second does the opposite starts at 4.5v and goes down to .7v as the throttle is opened.

Going through wire and modules, nothing popped out. Got a rebuilt TIPM and installed it. Was able to communicate with the pcm through the dlc. The ect and cel were still on. Checked back the next day. Connected to the dlc and looked at the diagnostic codes. Went ahead and cleared them. One of the codes was for a oil pressure sensor. Went and checked the 5v, signal and ground on it. It was unplugged from previous troubleshooting. The 5v and ground tested at 5v and ground the signal wire 4.5v when unplugged to the sensor and went to 0 at the sensor. Looked back at the dash and noticed the ect light was gone. Trying starting the car and was successful. Was able to repeat the car start. The oil pressure light was still on. Thought it might be because the car was on jack stands and lifted in the front. Oil dipstick showed below the mark for oil level. Lowered the car to ground and dip stick had the oil level in between the lines. Tried starting the car. The car was able to start but still showed the oil pressure light and cel. I checked the throttle position on the scanner and when hitting the accelerator the pcm showed the change in throttle position. The ect system seems to be working.

I'm going to put the original oil pressure sensor back in and see if that clears up the oil pressure warning and cel.

Not sure why a damaged TIPM would cause the ect light. But looks like the ect system is part of the ASD circuit and if there is an issue it won't let you crank the car. The only thing that pointed to the TIPM was that you couldn't connect through it as a bridge to the can bus to read the pcm and you could read the pcm if you connected to the can bus directly without going through the TIPM.

There's still a rodent running around and in the car. Haven't found any more damaged wires after pulling most of the interior but found evidence of it's presence in the cabin, trunk, engine bay and on top of the roof.

I'd check if there still is a draw on the battery. But It's probably still there as I unplugged the tipm before and it still showed as .185A. The spec is less that .035A.

Last edit: 10 months 1 week ago by ChallengerDude.

Please Log in or Create an account to join the conversation.

- Monde

-

- Offline

- Elite Member

-

Less

More

- Posts: 220

- Thank you received: 43

10 months 1 week ago - 10 months 1 week ago #84156

by Monde

Assuming is never a good thing.

Replied by Monde on topic 2009 dodge challenger rt with 5.7 engine no crank, no start and no communication

Happy to hear that the car starts after replacing the TIPM. As far as the oil pressure switch, if the wiring integrity is good and you have good oil pressure, the switch must be defective.

If you reinstall the old switch and the light still comes on, you may need to remove the switch and check the oil pressure and compare it to specifications. If pressure is okay, we may need to revisit the wiring before getting a new switch.

As far as the ETC, usually the pcm commands the throttle motor based on inputs from the accelerator pedal. The ETC needs power and ground that may be provided by the tipm and the pcm. I don't have a wiring diagram of the ETC, I cannot elaborate more on that.

If you reinstall the old switch and the light still comes on, you may need to remove the switch and check the oil pressure and compare it to specifications. If pressure is okay, we may need to revisit the wiring before getting a new switch.

As far as the ETC, usually the pcm commands the throttle motor based on inputs from the accelerator pedal. The ETC needs power and ground that may be provided by the tipm and the pcm. I don't have a wiring diagram of the ETC, I cannot elaborate more on that.

Assuming is never a good thing.

Last edit: 10 months 1 week ago by Monde.

Please Log in or Create an account to join the conversation.

Time to create page: 0.380 seconds