Still have a shudder at idle no new codes. Thinking intermittent rich condition

- Deadbolt Don

-

Topic Author

- Offline

- New Member

-

- Posts: 4

- Thank you received: 1

Bought with a bunch of and permanent codes and some pending/stored.

For reference the original 8 codes some duplicates.

P 0172 Fuel system 1/1 Rich

P 0300 Multiple cyl miss fire

P 0301 < cyl 1 missfire

P 0219B Bank 2 air-fuel ratio imbalance

P 3202 sensor 1/1 heater circuit high

P 2096 Downstream fuel trim system 1 lean

P 0562 Battery low voltage

P0132 o2 sensor circuit high

P0172 & P0300 repeat a couple times as pending then stored.

Just did oil filter housing, air filter, plugs, replaced injectors and coils with cheap amazon stuff. Learned a lesson LOL . Most pending codes left but kept giving p0300 p0175.p0175 rich. Cleaned and tested & reinstalled old injectors and coils. Also replaced upstream bank 1&2 02 sensors, PCV replaced and the MAF, the purge soleniod was swapped with a used one Throttle body was filthy and I cleaned it before reinstalling.

Runs better, the first few "cold starts" it would show a p0302 miss fire cyl #4 but never stored it. I could clear the codes after a warmup and the missfire never returned until next cold start.

Now not setting any pending codes and the I/M monitors on my scan tool are green except the EVAP.

There is a stutter at idle I can still feel. I can see the 02 live data doing the wavelength but it also shows a bunch of "noise" in the rich side sometimes.

At idle on a "cold start" LTFT is sitting around -3.1% on B1 -3.9% on B2 STFT is between -3.5% and -6.3% When warmed up I am sure STFT was around -3%.

I used a bluetooth scanner and torque app to check the DTC and it showed a "historic" code of P0321. But none of the other scan tools sniffed that one out.

There are still 3 permanent codes for:

P2198 Bank 2 air-fuel ratio imbalance

P0032 O2 heater high B1 S1

P0132 O2 sensor 1/1 circuit high

I have read that the downstream 02 on these vehicles does not alter the fuel delivery? But since I have one spare 02 would it be worth trying to swap out say B2 S2.

I know that trim values in the 0-5% are not much concern but is it possible there is a ign. problem that is causing a intermittent rich condition visible in the 02 data? Testing these coils is a pain because they are under other stuff.

I am wondering if it is timing related (cam position sensor) but without actually setting new codes I am not sure how to find the shudder @ idle. Has lots of power and the gauge says we can get reasonable mileage if wasn't for all the idling.

Compression is good for a motor with 232000KM on it .

Cyl 1 >147

Cyl 2> 147

Cyl 3> 145

Cyl 4> 145

Cyl 5> 148

Cyl 6> 145

I feel chasing a lean condition is probably more common/easier. Rich on F/I engines puzzles me.

Please Log in or Create an account to join the conversation.

- Deadbolt Don

-

Topic Author

- Offline

- New Member

-

- Posts: 4

- Thank you received: 1

Tempted to grab some coils from a wrecker yard.

Any chance I can reinstall cam sensors from a used vehicle? I think I can do a relearn through the AlfaOBD app.

Hate throwing more parts at it but the wrecker only wants $10 each for coils/injectors/cam sensor. At least then it is OEM stuff. This yard does mark mileage on their vehicles as well.

Please Log in or Create an account to join the conversation.

- Paul P.

-

- Offline

- Platinum Member

-

- Posts: 455

- Thank you received: 195

Quick Recap of the Situation

- Engine: 2013 Dodge Caravan 3.6L Pentastar

- Current status:

- No new active codes, just 3 permanent (P2198, P0032, P0132)

- STFT: around -3.5 to -6% on both banks at cold idle

- LTFT: around -3 to -4% warm

- Stumble/stutter at idle only

- Cleaned TB, replaced upstream O2s, PCV, injectors, MAF, plugs, purge

- Old coils/injectors were reinstalled after “Amazon regret”

- Compression within 3% across all six cylinders

- One historic P0321 (CKP fault) on a Bluetooth tool only

✅ 1. Fuel Trims & Rich IndicatorsYou’re absolutely correct—these trims aren't extreme, but together with the permanent P2198 (B2 rich bias) and stutter, they're telling us something isn’t quite balanced

.✅ 2. O2 Heater Code P0032 (B1S1) + P0132 High VoltageThis is key:

- P0032 = B1S1 heater stuck ON/high current

- P0132 = B1S1 signal over 0.9V too long

So your slight negative trims might actually be hiding a false rich condition due to a biased upstream O2.🔎 DIAG PATH FOR YOU TO FOLLOW:An O2 sensor with a lazy or stuck-high output (from heater bleed-through or circuit failure) may fool the PCM into trimming fuel out, believing it's rich—even when it's not.

🔧 Step 1: Validate B1S1 O2Even if it's new, swap in your known-good O2 sensor here. (Forget B2S2 for now; it's not your fuel trim controller.)

- Graph B1S1 live voltage on a scope or scan tool

- Watch if it:

- Sticks high (>0.9V)

- Oscillates lazily compared to B2S1

- Takes longer to go lean when throttle snapped

🔧 Step 2: Look for Cross-Bank CausesThe fact that both banks are equally rich (-3 to -6%) suggests:

- Overfueling from fuel pressure regulator, leaky purge, or MAF drift

- Or a single sensor (like MAF or MAP) misinforming the PCM

- Your engine size: 3.6L = ~4.8g/s per liter at hot idle = ~17g/s expected

- At idle: see if MAF reports too high (20g/s+) = overreporting → trims pull fuel

- Also graph MAF vs RPM vs VE (you’ve got ScannerDanner mindset—try this math)

Yes—intermittent weak spark (especially at low rpm) = partial combustion = excess HC = rich feedback But:

- You’d expect STFT to go high (adding fuel) if it saw unburned O2

- If it sees false richness instead, O2 may be biased

- Power/brake boost hose for vacuum leaks causing idle cylinder to misfire/stumble

- Coil secondary waveforms if you’ve got a scope

- Or cylinder drop test by disabling coils one at a time (scan tool or manual pull if accessible)

- Slight idle lope/stutter

- Fueling imbalance without hard misfire

- But… it’s a stretch without a code or cam correlation data

- Run a cam/crank correlation waveform on a scope (if available)

- Watch for consistent pattern vs known-good

- If not, table it for now

- Smoke test the intake one more time—especially around injector seals and PCV hose

- Purge test: Clamp purge line, watch fuel trims go less negative at idle?

- Power balance test if you have bidirectional scan tool

- Try adding propane (gently) at idle → if STFT goes from negative toward 0, it's truly rich; if not, it's a false lean

🔑 The idle stutter + negative trims + heater fault = upstream O2 is your first suspect. Everything else (ignition, purge, MAF) can be ruled in/out after that.

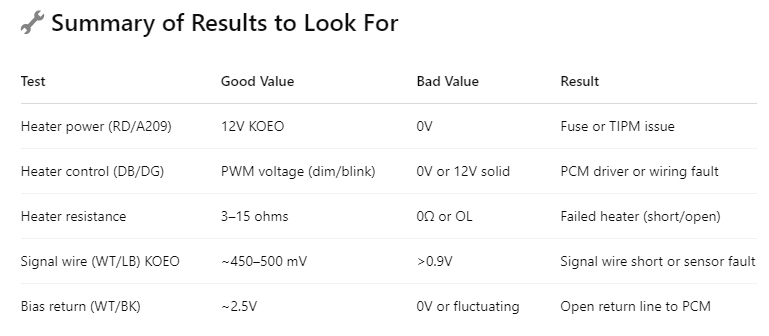

1. Check Heater Circuit (P0032)P0032 = O2 Heater Control Circuit High → usually means short-to-power, failed heater, or PCM driver fault💬 “Rich” isn’t always too much fuel—sometimes it’s too little air, or a lying O2 sensor with a heater short that says “feed me less.”

.🔋 Step A: Check for Power

- Key ON (engine off)

- Backprobe heater power wire

- Should see ~12V+ on the power side (ASD-fed)

- If not, check fuse, ASD relay, or harness

- Connect multimeter across heater power and ground wires

- Start engine → you should see 12V across the heater

- Or test heater ground wire to chassis ground:

- Engine running → should pulse or show low resistance to ground

- Unplug sensor, measure heater pins across connector

- Normal range: 3–15 ohms

20 ohms or OL = open heater

- 0 ohms = shorted heater

✅ 2. Check O2 Signal Wire (P0132)P0132 = O2 Signal High (stuck above 0.9V)❗ If the heater is shorted internally, it can bleed voltage into the signal wire, triggering P0132 (voltage high).

📏 Step A: Key ON, engine OFF — check voltage on signal wire:

- Should read around 450 mV (bias voltage) from PCM

- If you see >0.9V, that could mean:

- Signal wire is shorted to 12V

- Heater circuit bleed into signal line (common if heater fails internally)

- Lightly tug/bend harness from sensor connector to PCM

- Watch for voltage jumps or dropouts

- If voltage fluctuates with movement → harness issue or corrosion in connector

Voltage DropASD

→ sensor power pin<0.5V dropHeater Ground DropPCM ground driver

→ chassis<0.5V dropSignal GroundO2 ground pin

→ battery groundnear 0VSignal WireO2 signal pin to PCM pin<1Ω resistance or <0.2V drop under load

🚩 Final Interpretation

Clear Tips Symptom Possible Root Causes:

B1S1 voltage stuck high (>0.9V) even KOEO

Signal wire short to power or failed sensor Heater circuit fuse pops repeatedly

Shorted heater element or wiring to ground

Heater ground shows battery voltage KOEO

Open driver in PCM or bad ground path

Resistance across heater = OLOpen heater circuit (replace sensor)

Never stop Learning.

Please Log in or Create an account to join the conversation.

- Deadbolt Don

-

Topic Author

- Offline

- New Member

-

- Posts: 4

- Thank you received: 1

So your slight negative trims might actually be hiding a false rich condition due to a biased upstream O2.🔎 DIAG PATH FOR YOU TO FOLLOW:

🔧 Step 1: Validate B1S1 O2Even if it's new, swap in your known-good O2 sensor here. (Forget B2S2 for now; it's not your fuel trim controller.)

\

🔧 Step 2: Look for Cross-Bank CausesThe fact that both banks are equally rich (-3 to -6%) suggests:🧪 MAF sanity check:

- Overfueling from fuel pressure regulator, leaky purge, or MAF drift

- Or a single sensor (like MAF or MAP) misinforming the PCM

- Your engine size: 3.6L = ~4.8g/s per liter at hot idle = ~17g/s expected

- At idle: see if MAF reports too high (20g/s+) = overreporting → trims pull fuel

- Also graph MAF vs RPM vs VE (you’ve got ScannerDanner mindset—try this math)

Still, check:🧪 Bonus Tests

- Power/brake boost hose for vacuum leaks causing idle cylinder to misfire/stumble

- Coil secondary waveforms if you’ve got a scope

- Or cylinder drop test by disabling coils one at a time (scan tool or manual pull if accessible)

🧠 Final Thoughts

- Smoke test the intake one more time—especially around injector seals and PCV hose

- Purge test: Clamp purge line, watch fuel trims go less negative at idle?

- Power balance test if you have bidirectional scan tool

- Try adding propane (gently) at idle → if STFT goes from negative toward 0, it's truly rich; if not, it's a false lean

🔑 The idle stutter + negative trims + heater fault = upstream O2 is your first suspect. Everything else (ignition, purge, MAF) can be ruled in/out after that.

💬 “Rich” isn’t always too much fuel—sometimes it’s too little air, or a lying O2 sensor with a heater short that says “feed me less

Thanks Paul lots of information to work with!

My buddy at the wrecker sold me all 6 coils and 2 cam sensors for $45. so I couldn't resist since I was there anyway.

I did change the coils and no real change. I swapped the B1S1 02 with another brand new sensor I had a extra of. Not sure yet if this made much difference. (was late last night when finished)

Fuel pressure testing on a 3.6L caravan - The regulator is part of the fuel pump assembly on these vehicles right?

Question on the MAF testing/readings.. My scan tool shows MAF at around 11 in/hg at idle, maybe I am not looking at the right place?

"Also graph MAF vs RPM vs VE" What is "VE"?

I am pretty sure there is no vacuum leak. I double checked the brake booster line as well as the purge soleniod hose. I did smoke test the intake using a DIY smoke machine. No visual leaks that I can find.

Because the IAT sensor is built in to the secondary air box right before the throttle body adding propane to there doesn't do a whole lot. I did see the trim values move closer to 0 or positive numbers very slightly.

I don't have a scope and even if I had one I feel I would be like the "donkey with a spinning wheel" - Nobody knows how I got it and be damned if he knows how to use it! LOL

Can I do a Cam relearn on the existing sensors? I have seen a few videos that have mentioned doing a ECU reset and relearn can help a "dieseling" idle.

I will play with this some more and try to get some graphs/numbers laid out better.

Please Log in or Create an account to join the conversation.

- Paul P.

-

- Offline

- Platinum Member

-

- Posts: 455

- Thank you received: 195

It's still leaning towards an O2 sensor. Chrysler's respond best to OEM sensor's IMO.

Here is the reply:

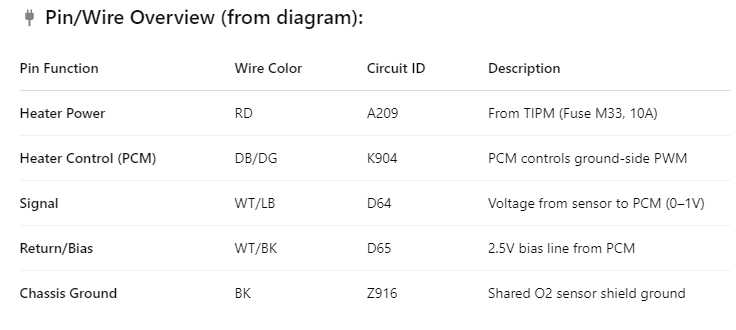

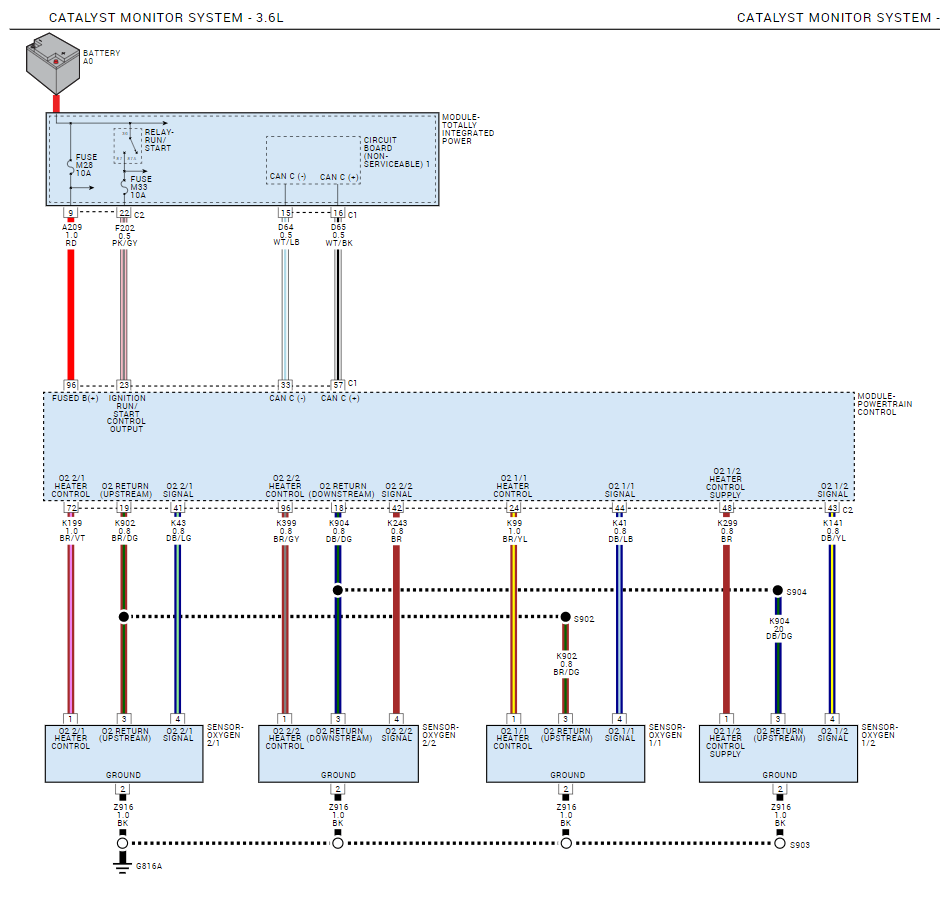

✅ Full Wiring Integrity Check – O2 Sensor 1/1 (B1S1) on 3.6L Pentastar

🔧 Component: O2 Sensor 1/1 (B1S1) Located on Bank 1, upstream, this sensor includes:

- Heater circuit (control side)

- Signal wire

- Sensor ground

- Bias return wire

How:

- Backprobe RD (A209) at O2 sensor plug

- With key ON, engine OFF, you should see ~12V

✅ 2. Heater Control Test (Ground side, DB/DG - K904)Goal: Check PCM's ability to ground the heater🔧 If not: check Fuse M33 (10A) in TIPM and TIPM relay output

How:

- Set multimeter between DB/DG (K904) and battery positive

- Start engine: you should see pulsed or steady voltage (~12V average) if PCM is grounding the circuit

- Or use a test light between K904 and battery (+). It should blink or dimly light

✅ 3. Heater Resistance Test (Sensor unplugged)Goal: Confirm heater isn’t shorted or open❌ No voltage = PCM driver failed or open wire

✅ Steady light = good PWM control

How:

- Measure resistance across RD (A209) and DB/DG (K904) at the sensor plug

- Should read 3–15 ohms

✅ 4. O2 Signal Voltage Test (KOEO)Goal: Check for stuck-high or false bias🔥 0 ohms = shorted → can bleed power into signal

⚠️ OL = open → won’t heat → sensor responds slow → fuel trim errors

How:

- KOEO, backprobe WT/LB (D64) – the signal wire

- Should read ~450–500 mV bias voltage (from PCM)

✅ 5. Bias Return Integrity Test (WT/BK - D65)Goal: Ensure bias return is intact⚠️ >0.9V = possible short to power, failed sensor, or heater bleed

❗ PCM disables feedback control if signal is pinned

How:

- KOEO, backprobe WT/BK (D65)

- Should also see ~2.5V bias

✅ 6. Wiggle and Load TestsIf this wire is open or corroded, PCM may read floating voltage on signal line

- While monitoring all above, gently wiggle the harness from sensor to PCM

- Check for voltage spikes or dropouts

- Optionally, load test each wire with a test light to confirm current-carrying ability

Never stop Learning.

Please Log in or Create an account to join the conversation.

- Deadbolt Don

-

Topic Author

- Offline

- New Member

-

- Posts: 4

- Thank you received: 1

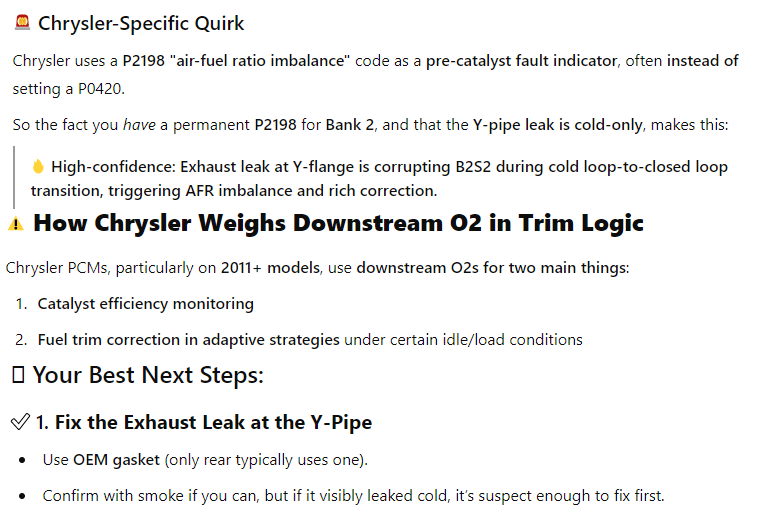

Turns out on a cold start I have a exhaust leak under the van at a connection flange. (just as the exhaust starts to head backward. It was actually pretty substantial. Really not to surprised since it sounds like it has a leak but every time I looked it never seamed to leak.Weird thing is after driving the van for a bit the leak appears to be gone. All coming out the tailpipe.

Could this "leak" cause the "fishbite" idle with no codes?

Does any one have a diagram of the exhaust connections and related gaskets? I have tried to find this before and found way to many different diagrams.

I think I will smoke test the exhaust once my new heated wire comes for the DIY smoke machine. Make sure there are not any other leaks. Or could this point to a plugged up exhaust. (Not sure it is bunged up. We did a seafoam upper cyl treatment where you empty a can through throttle body and then let it hot soak. When we fired it up we got the smoke plume that follows that treatment).

Edit : After watching a few videos it appears it is the connection from the cat. pipes to the y pipe.

Is there only 1 gasket on there-looks like rear is the only one that uses a gasket?)

I am sure that is where mine was leaking.

Also I know my flex pipe mesh is loose but maybe a leak there as well. I guess I will be able to see a leak if there is one when I smoke test the exhaust.

Please Log in or Create an account to join the conversation.

- Paul P.

-

- Offline

- Platinum Member

-

- Posts: 455

- Thank you received: 195

Never stop Learning.

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4992

- Thank you received: 1115

I don't want to derail your process but I have seen burned and chipped valves on these that will barely miss at idle and clear up under load.

If you can use the data to narrow it down to a single cylinder that's misfiring that most, it may be worth while to perform a leak down test on that cylinder.

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.