Hemi 5.7 Just Rebuit engine, Crank no Start

- Mars928

-

Topic Author

- Offline

- Junior Member

-

- Posts: 30

- Thank you received: 2

On the timing, I set it as follows: #1 cylinder at TDC, crankshaft's keyway at 30° / 2 o'clock position, which places the timing divot on the bottom, camshaft with the divot mark pointing straight up. Chain's single colored link on the camshaft mark and the double colored links stradling the crankshaft divot on either side of the mark. I turned the crank several rotations afterwards, making sure the cam's mark was pointing up cylinder #1 at TDC each time. Unless you spot a flaw in that procedure, it should be ok. As I mentioned, I re-opened the front end and re-did the timing again just to make sure. I hope I did the right procedure.

I made sure that the valves were going up and down after installing each of the rocker arms. I was aware of the different length between the exhaust and intake pushrods. I also turned each one of them with my fingers and rocked them side to side to make sure they were seated on the lifter after turning the crankshaft a couple of times. But clearly, something went wrong.

The fact that there is no air coming out of the spark plug hole when cranking the engine, points to the valves being closed.

I am going to pull the covers to see what the valves are doing. I will definitely do a leakdown test to see what I can find out.

Get out the popcorn...Mario

Please Log in or Create an account to join the conversation.

- Mars928

-

Topic Author

- Offline

- Junior Member

-

- Posts: 30

- Thank you received: 2

I decided it was too much and we took the engine out again. Once the intake manifold/plenum was removed I confirmed that not only were all the valves open on bank one, but ALL also on bank two. Can't be possible, right? All at the same time? Also, a valve on each bank looked like it was open about 7/16 to 1/2"!!!

I thought that for sure, I had reversed the pushrod installation.I observed carefully, all valves went up and down as the engine was rotated. I breathed a momentary sigh of relief, thinking I had found the problem. But of course, I doubt that the pushrods could be installed in the wrong place. They were in the right place, short intake, long exhaust. Well then, maybe I was sent the wrong pushrods. I still had the ones I had removed and the length on both were the same between old and new. The pushrods were not bent, no deflection at all.

Well then maybe I got the wrong lifters. I compared them to the original and they were identical. That's where I stopped.

Now I am thinking, could it be the wrong cam? The valves? What the heck is going on here? Any ideas guys?

Sorry for the long post. I am so bummed out, to say the least. Cheers!

Mario

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4957

- Thank you received: 1111

Hopefully no valves got bent.

Keep us posted Mario

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- juergen.scholl

-

- Offline

- Platinum Member

-

- Active partschanger

- Posts: 1230

- Thank you received: 462

An expert is someone who knows each time more on each time less, until he finally knows absolutely everything about absolutely nothing.

Please Log in or Create an account to join the conversation.

- Mars928

-

Topic Author

- Offline

- Junior Member

-

- Posts: 30

- Thank you received: 2

Juergen:

Good point. I did not bleed the lifters. Over the last two weeks, I did a lot of cranking trying to start this thing before doing a compression test and finding out the intake valves were open. Could the lack of lifter bleeding still be an issue at this point? I haven't checked if the exhaust valves are also open. I did a leak-down test and all the air was coming from the throttle body. I could not detect any air coming out of the exhaust.

I have bank one head removed; I will check the exhaust valves on the other head. I will remove the bank one lifters and bleed them. I will re-install the rocker arms and see what happens. That is the least I can do.

If you guys have any other suggestions, please let me know.

Thank you for chiming in.

Mario

Please Log in or Create an account to join the conversation.

- Mars928

-

Topic Author

- Offline

- Junior Member

-

- Posts: 30

- Thank you received: 2

I put the heads and rocker arms back on but the intake valves are all open still. One at least 1/2". The headers are mounted so I don't know about the exhaust valves but it seems that is a moot point, given the intake valves issue.

The cam shaft is the last thing to check. A major dissasembly, unfortunately.

What else could I do?

Thanks

Mario

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6063

- Thank you received: 1531

Please Log in or Create an account to join the conversation.

- Mars928

-

Topic Author

- Offline

- Junior Member

-

- Posts: 30

- Thank you received: 2

I have been mulling something else. Up to this point, I have not considered the valve height to be the problem, although that certainly could be. I had the heads done (seats replaced, new valves, guides, seals, springs, etc.) at a local shop with a very good reputation, so I trusted their expertise. At this point, I am having my doubts. Just maybe.

I have just now become aware that the difference in installed height between the early 5.7 and the later Eagle 5.7 is .20". I will check tomorrow what the height of the spring in the closed position is. As far as I found out, the early engine's valve height should be 1.80 and the newer ones 2.0" high. It's possible that .20" difference (if it's there) could be the problem. I will check the manual for reference to be sure.

So, the hunt for a solution grinds on.

Mario

Please Log in or Create an account to join the conversation.

- Mars928

-

Topic Author

- Offline

- Junior Member

-

- Posts: 30

- Thank you received: 2

The height of the installed springs is 2". The specs call for a 1.81" height. I admit I should have checked that myself. Nevertheless, I got royally screwed by the machine shop. They have been in business 50 years, the ultimate pros. NOT! This is what I get for trusting the so-called pros.

I will see what they have to say.

Looking at the pictures of the intake valves I took with the rocker arms installed, the valves that should have been closed look like they were open about .20".

Seems to me the mystery has been solved. Now the grind to put it all back together properly.

I will let you know how it turns out in about 2 weeks.

To those of you who contributed advice:

Thank you

Mario

Please Log in or Create an account to join the conversation.

- Mars928

-

Topic Author

- Offline

- Junior Member

-

- Posts: 30

- Thank you received: 2

Please Log in or Create an account to join the conversation.

- Mars928

-

Topic Author

- Offline

- Junior Member

-

- Posts: 30

- Thank you received: 2

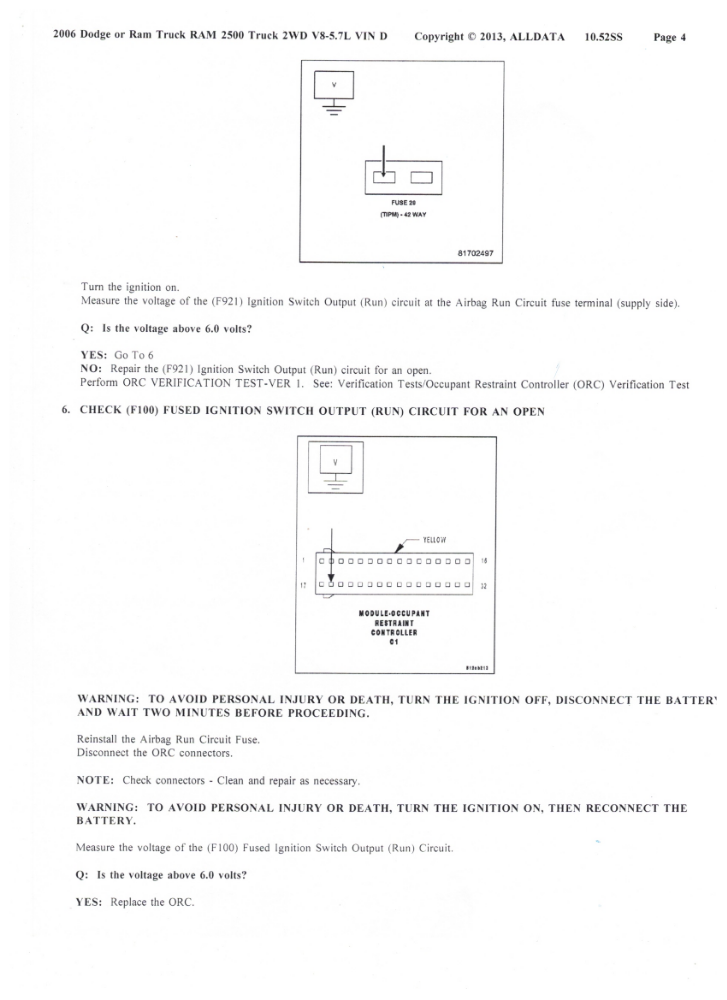

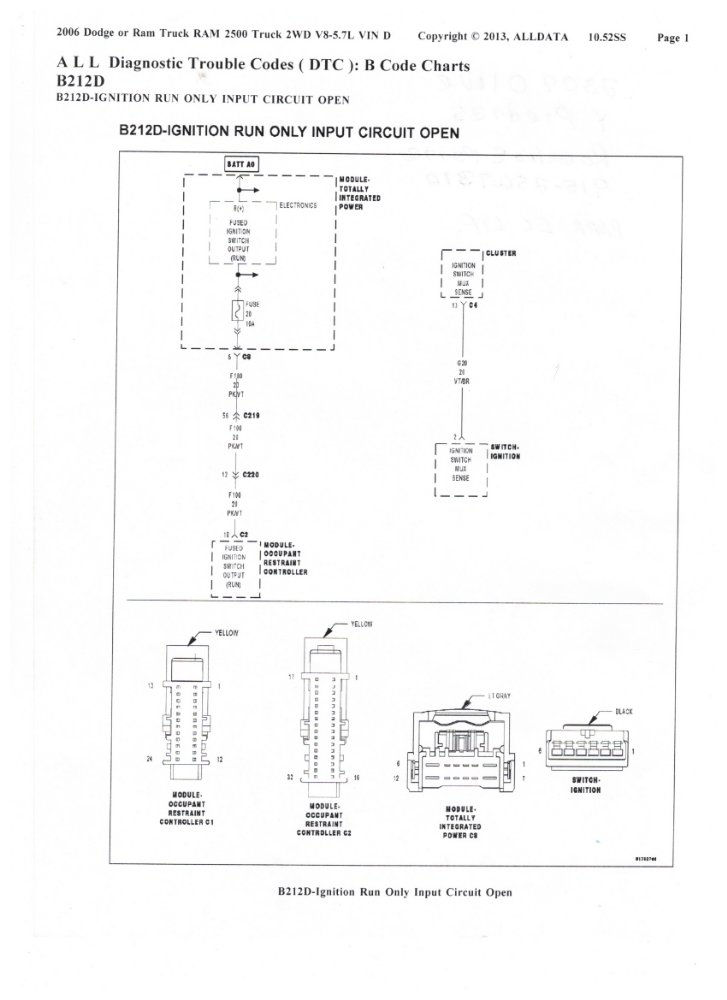

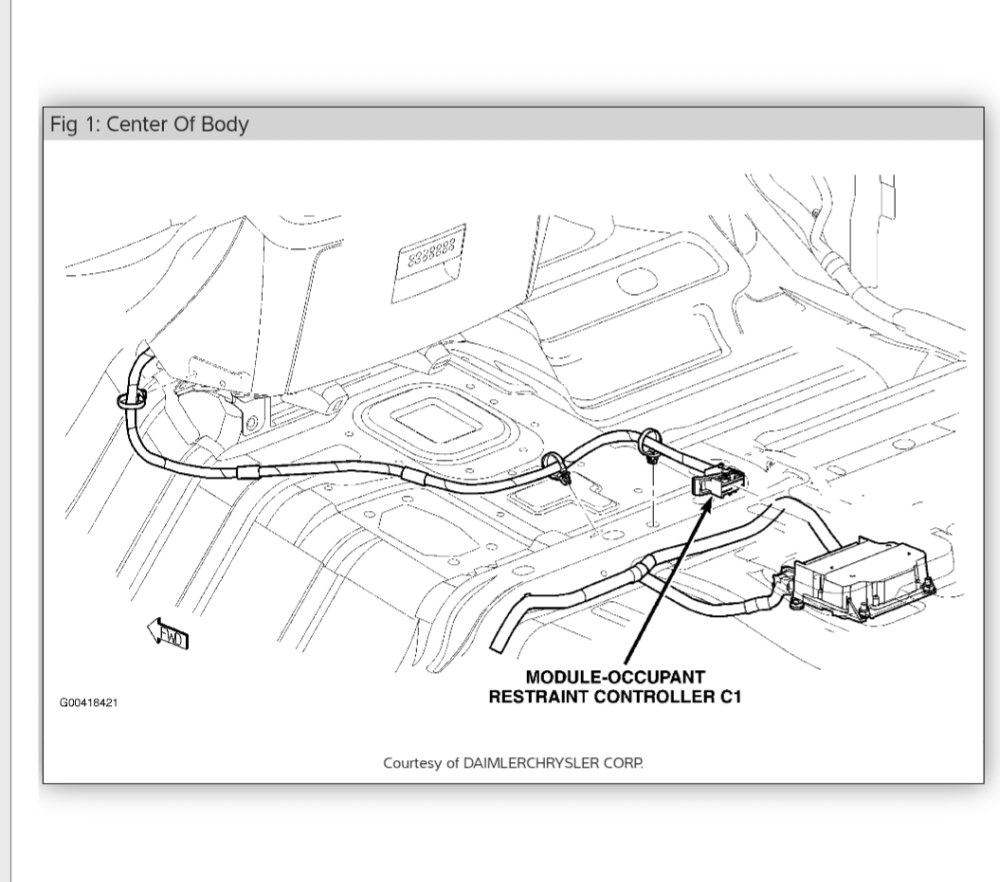

I am getting code B212D, Ignition Run Only Input Circuit Open. I went through the repair procedure but I am stuck on step 6. It's asking to check (F100) output. I have not been able to locate the Module-ORC (please see the first diagram), to test.

Anyone have information on this?

I have been waiting for a "pro" to come take a look but he just says "he will call me when he has time", after failing to show up on a missed appointment. Of course he didn't call to let me know he was't coming. I am looking for someone else, but in the meantime, hopefully someone can help.

Thank you

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4957

- Thank you received: 1111

While an ignition run voltage output missing could certainly cause an issue, this code seems to only effect the ORC module.

If you aren't getting a similar code in the engine control module, I don't think this is going to be the cause of the no start condition.

Back to basics: spark, fuel and compression.

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- Mars928

-

Topic Author

- Offline

- Junior Member

-

- Posts: 30

- Thank you received: 2

The cluster lights come on when the key is turned to the start position but there is no crank. I did jump the starter solenoid terminal and it does crank normally, just not with the key.

Please Log in or Create an account to join the conversation.

- Mars928

-

Topic Author

- Offline

- Junior Member

-

- Posts: 30

- Thank you received: 2

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4957

- Thank you received: 1111

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- Mars928

-

Topic Author

- Offline

- Junior Member

-

- Posts: 30

- Thank you received: 2

I think I found the problem, although I am not 100% sure. What happened was, when I was checking all the fuses prior, the fuse to the park lights indicated a short. I decided to look into it to eliminate yet another problem. I started to follow the wiring, just a random wiring loom going to the PCM using a Power Probe ECT 3000. It was indicating a short on the device and as I followed the loom, it stopped flashing in the area above the throttle body. I peeled the loom cover a few inches but I could not really see anything because the wires were tightly wound.

I figured I would get to it later. I went inside the truck and turned the ignition on for some reason and noticed the transmission letters were not ALL on, like I had been seeing them all this time, only the "P" letter one was on. I had a feeling something was different this time and indeed it was. The engine cranked and started immediately.

I turned it off after about a minute and tried again. All the selector lights were turned on again and it did not crank. I went and jiggled the said wires and only the P light stayed on. Of course, it started right away. I need to follow up with the wires situation. There has to be a problem there. Maybe we pinched them when installing the engine.

It seems this long running saga has come to an end. Not solved entirely, but a good clue.

As luck would have it, I noticed a big puddle of transmission oil on the floor just for running the engine a couple of minutes. Turned out one of the cooling lines had a hole in it close to the oil filter. What are the chances?

Anyway I managed to cut out a piece of line and will be using some NS fittings to hopefully patch it up.

Long story to a long running ordeal.

Thanks to all who chimed in.

Mario

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4957

- Thank you received: 1111

Glad to hear you got it back in action, even if you've got a transmission harness issue to track down now, it must be satisfying to hear it run after all you've gone through.

Nice work sticking through it.

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- Mars928

-

Topic Author

- Offline

- Junior Member

-

- Posts: 30

- Thank you received: 2

Please Log in or Create an account to join the conversation.