08 Kia Sportage 2.7L LEAN Both Banks

- Andrew Parry

-

Topic Author

- Offline

- Junior Member

-

- Posts: 30

- Thank you received: 1

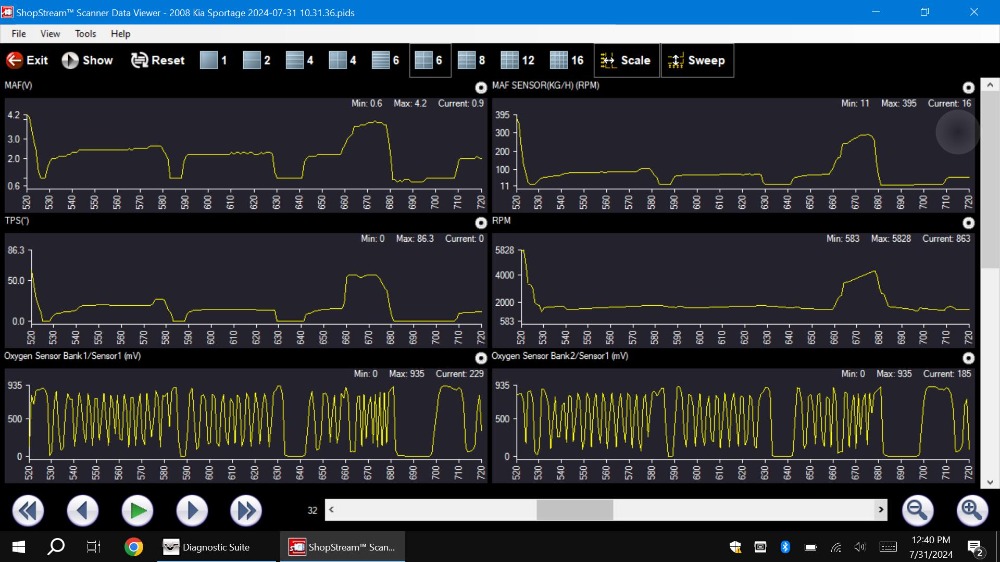

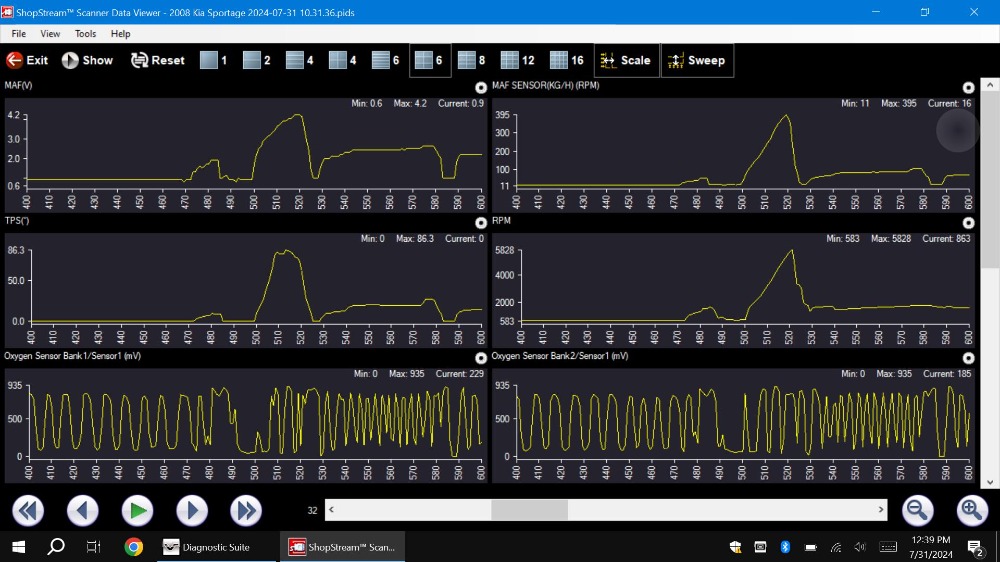

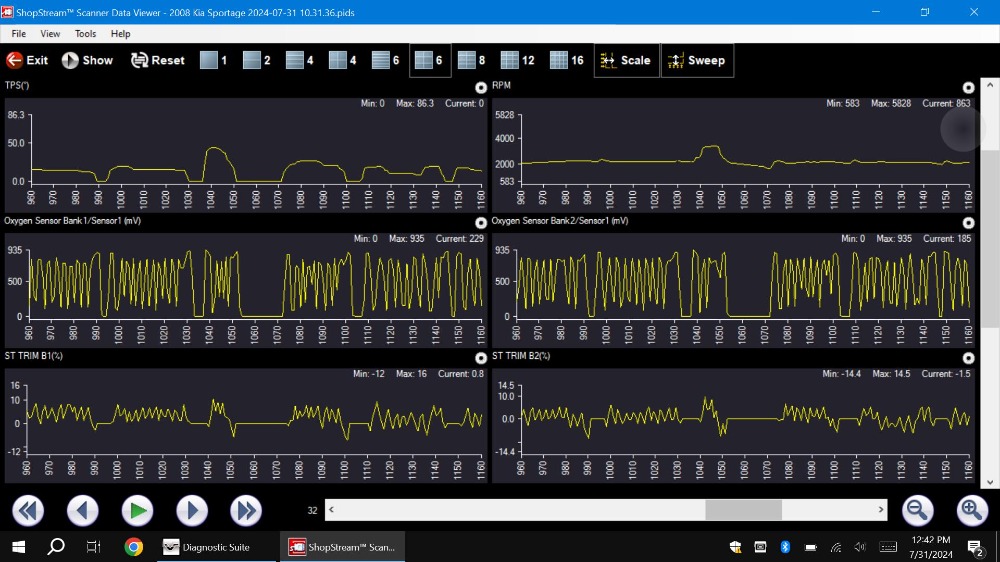

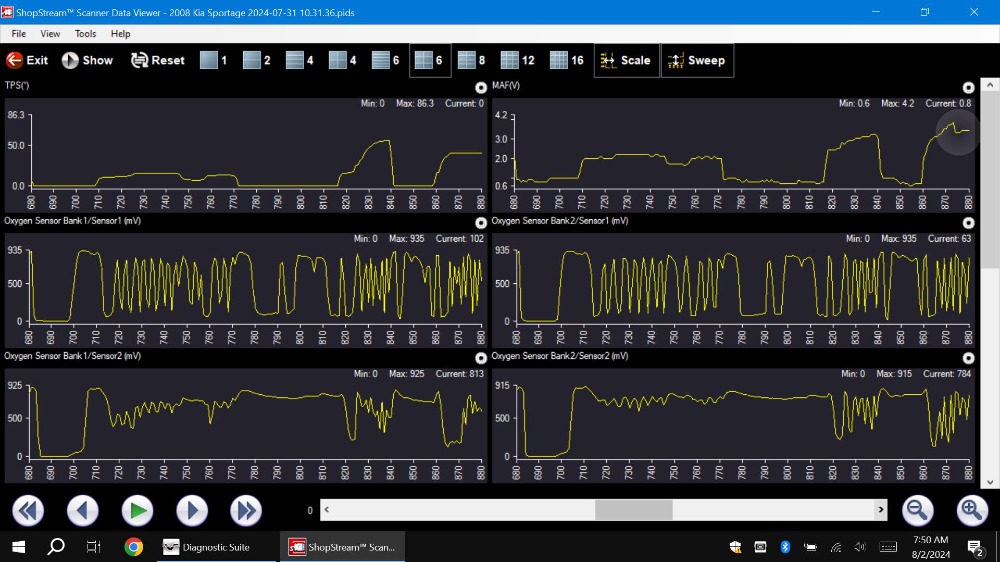

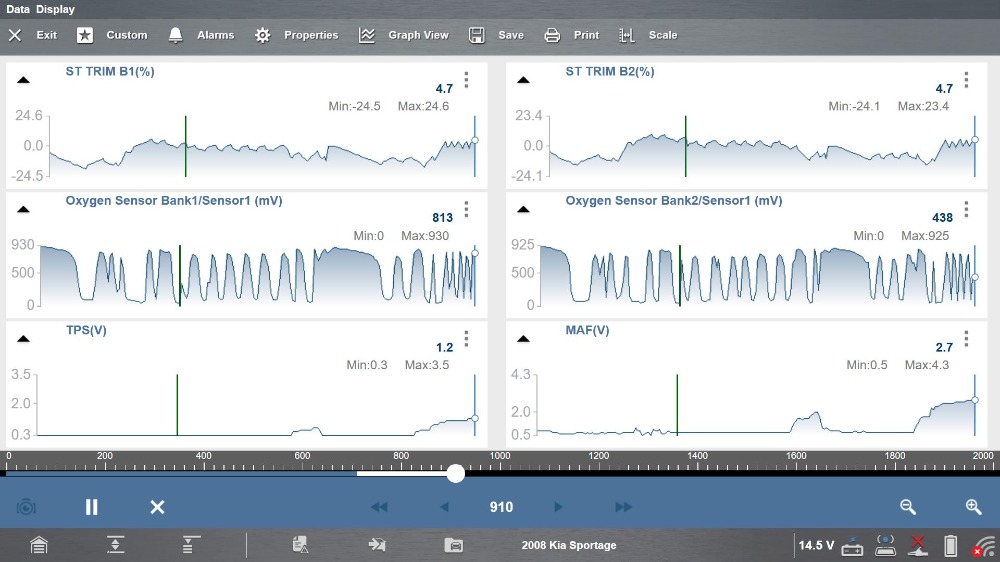

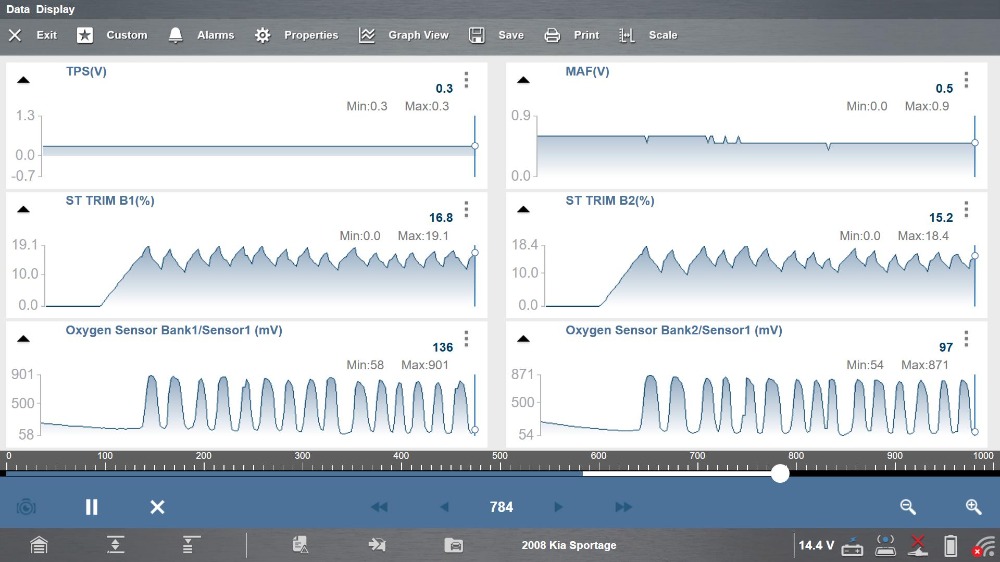

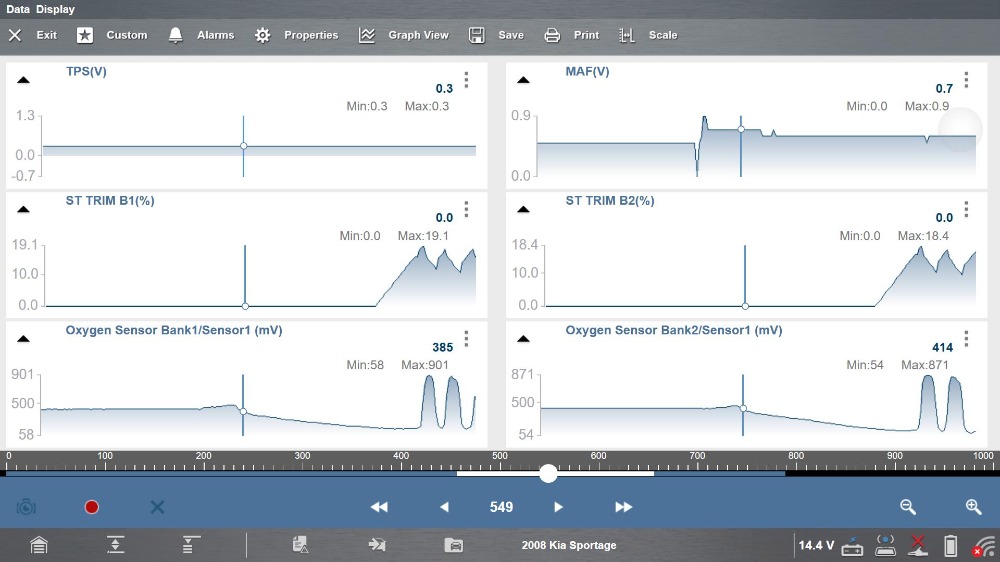

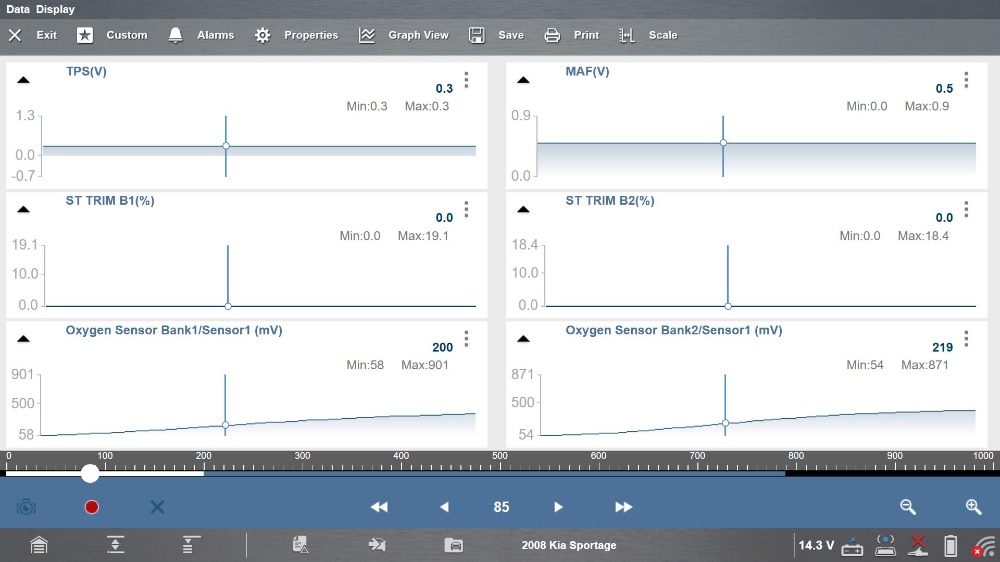

I am almost embarrassed to be asking about what SHOULD be a simple find. Im not sure why but I am having a hard time with it. I put a new (used) motor in this thing back in the spring for the customer. engine blew up, vehicle was towed, dead battery, no previous codes available. new engine runs great, customer is happy. comes back a week later with lean codes both banks and LTs are matching at 15% and STs are very close to one another, within 1-3 percent at all times. with dead matching trims, I am not anticipating oxygen sensors or anything. thinking either air leak, or MAF. Customer is nice and understanding. I have tinkered with it on a few different occasions for them over the last couple months. I smoke tested the intake, cant find a leak anywhere. sprayed the intake down with carb/brake clean, cant get any change in trims or rpm. MAF, according to SI, is right where it should be on the data pid, both at idle and at 2,000rpms. (I admit I suck at properly diaging MAF so if further tests I should do, let me know!). Oxygen sensors match one another, switching nicely. They go rich on WOT like they should. every once in a while, one of them DOES get stuck, sometimes RICH sometimes LEAN only AFTER a WOT event. but when they are stuck it seems to have no bearing on the trims in a faulty way. I checked the purge valve, because the STs go negative when you first start it up, thought maybe it was sucking in vapor from tank, then maybe getting fresh air after that - pinched the lines, no change at all in trims.

I did also clean the MAF and swap over the original throttle body (thinking maybe a bad IAC valve) but that also resulted in no change.

lets just pretend I know nothing, and have done no tests so far lol. where do you recommend I start?

Thank you all for the help!

Please Log in or Create an account to join the conversation.

- Andrew Parry

-

Topic Author

- Offline

- Junior Member

-

- Posts: 30

- Thank you received: 1

Please Log in or Create an account to join the conversation.

- Monde

-

- Offline

- Elite Member

-

- Posts: 220

- Thank you received: 43

Assuming is never a good thing.

Please Log in or Create an account to join the conversation.

- Andrew Parry

-

Topic Author

- Offline

- Junior Member

-

- Posts: 30

- Thank you received: 1

I thought I had figured it out today. I started studying the fuel system, and noticed that the fuel rails were actually different. So I swapped them, but no change in trims.

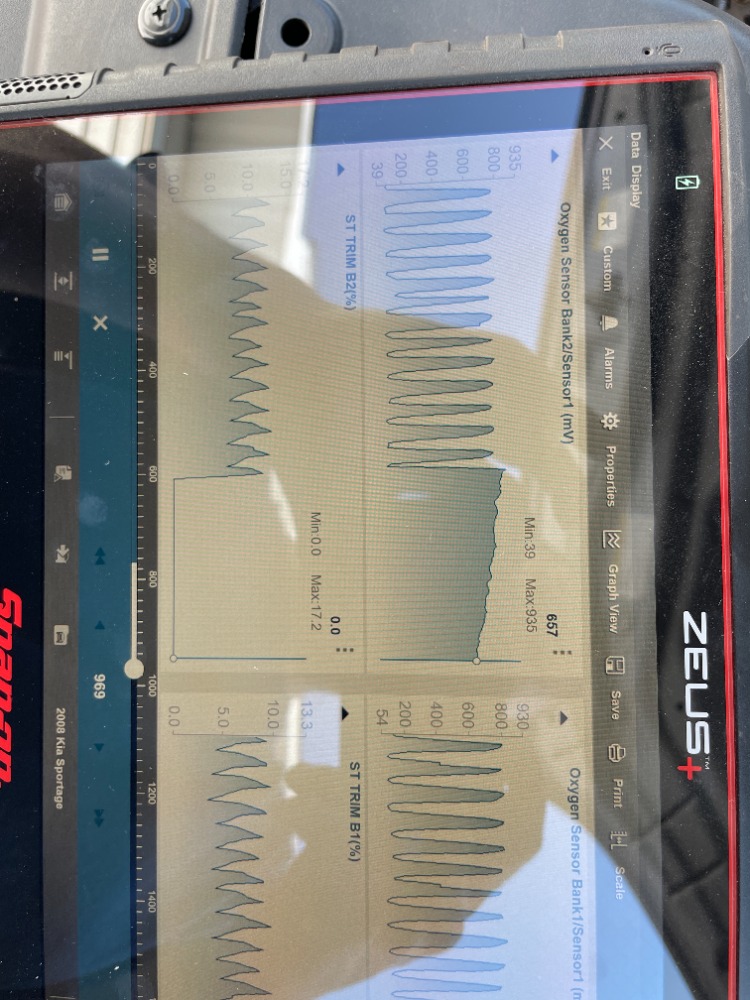

So here is another attempt, I induced propane into the system to try and get these O2s to STICK RICH. I havent tried this very often, so again, I am not sure what to expect. But, the O2s never stuck rich but kept on switching, as I slowly increased the propane. when the trims go to 0, is when it stalled. Sorry my picture sucks, and I didnt get the other side in the photo, but the other O2 did the same thing. But I am just using the regulator on my torch, so hard to tell how much or how little I am putting in. is there a better way I should be doing this?

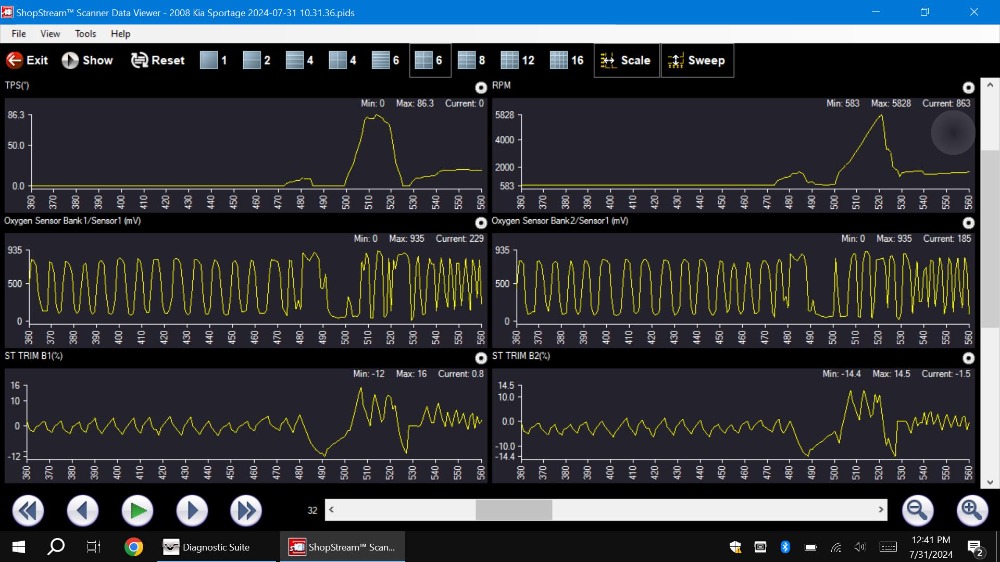

I do notice that the B2 ST trim is often a few percent higher than B1, as in this picture. sometimes they are equal, sometimes B2 is a little higher. But LTs dont change from 15%.

Please Log in or Create an account to join the conversation.

- Monde

-

- Offline

- Elite Member

-

- Posts: 220

- Thank you received: 43

Hopefully, someone who has seen this before will intervene.

Assuming is never a good thing.

Please Log in or Create an account to join the conversation.

- Andrew Parry

-

Topic Author

- Offline

- Junior Member

-

- Posts: 30

- Thank you received: 1

Please Log in or Create an account to join the conversation.

- Monde

-

- Offline

- Elite Member

-

- Posts: 220

- Thank you received: 43

Assuming is never a good thing.

Please Log in or Create an account to join the conversation.

- Monde

-

- Offline

- Elite Member

-

- Posts: 220

- Thank you received: 43

Assuming is never a good thing.

Please Log in or Create an account to join the conversation.

- Andrew Parry

-

Topic Author

- Offline

- Junior Member

-

- Posts: 30

- Thank you received: 1

Please Log in or Create an account to join the conversation.

- Chad

-

- Offline

- Moderator

-

- I am not a parts changer.

- Posts: 2129

- Thank you received: 715

I'm with Monde. You need to check fuel pressure at WOT.I am not sure how to interpret the switching at WOT. O2 sensors should go rich at WOT unless you have a fuel delivery issue.( Lean O2s).

"Knowledge is a weapon. Arm yourself, well, before going to do battle."

"Understanding a question is half an answer."

I have learned more by being wrong, than I have by being right.

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4957

- Thank you received: 1111

I may be in the minority, but I have seen the o2s continue to switch at WOT. They don't appear to drop dead lean under load. If fuel deliver is suspected to be inadequate, a fuel pressure test will with a gauge T'd in will answer that question.

I would be interested in the freeze frame data: under what conditions did the lean codes set, as well as the fuel trim (long term and short term for both banks) at various RPMs.

Sorry for leaving you hanging, IDK why my last post didn't make it....

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- Andrew Parry

-

Topic Author

- Offline

- Junior Member

-

- Posts: 30

- Thank you received: 1

I am starting to think that there is something weird between the different motors. It came out of the same exact year and model. BUT yesterday I noticed that the fuel rails were different! (I was so excited, thought I found the issue!) I swapped the rails and injectors, from the original motor over to the replacement, and there still wasnt any change. But it makes me wonder, if there is something weirdly different about these motors. Cal vs Fed emissions, or something, idk. Repair link doesnt give any varying details. same vehicle basically.

vehicle vin: KNDJE723587496132

donor motor vin: KNDJE723187497312

Please Log in or Create an account to join the conversation.

- Andrew Parry

-

Topic Author

- Offline

- Junior Member

-

- Posts: 30

- Thank you received: 1

Please Log in or Create an account to join the conversation.

- Chad

-

- Offline

- Moderator

-

- I am not a parts changer.

- Posts: 2129

- Thank you received: 715

yesterday I noticed that the fuel rails were different! (I was so excited, thought I found the issue!) I swapped the rails and injectors, from the original motor over to the replacement, and there still wasnt any change. But it makes me wonder, if there is something weirdly different about these motors. Cal vs Fed emissions, or something, idk.

When I first read that, I was excited for you, too.

A couple of months ago, I had a 2002 Ranger with a 3.0 come in. The customer had just bought it and it was running rich.

The Cornwell tool truck guy stopped in while it was here. He pointed at it and said that he used to own it. He sold it to the guy that sold it to the guy that brought it to us. He said that it has had this problem for a long time and had been to several shops.

To make a long story short, the 2002 3.0 had an option of flex fuel (VIN V) or non-flex fuel (Vin U).

This truck was non-flex fuel but, had flex fuel injectors in it, which are different part numbers.

I installed the proper fuel injectors and all was well.

"Knowledge is a weapon. Arm yourself, well, before going to do battle."

"Understanding a question is half an answer."

I have learned more by being wrong, than I have by being right.

Please Log in or Create an account to join the conversation.

- Andrew Parry

-

Topic Author

- Offline

- Junior Member

-

- Posts: 30

- Thank you received: 1

For giggles, I swapped the intake manifold yesterday as well at 5:30 before I quit, and the customer came and got it in the evening. torqued the manifold down. new gasket. checked hoses. no air leaks.

But, I checked the trims afterwards and short term was going rich still, so I dont think that was the issue, either. This is very frustrating. they are actually friends of mine, and so I want to help them out. I dont know what to do except throw some O2 sensors and a MAF at it, but I am almost certain they are fine.

do the O2s look like they are trending too far lean upon start up? I wonder if the O2s both have a trend too far lean? idk. But then there are those times (I sent a screen shot last message) where the O2s stick rich, when under no throttle or load (usually right after a light throttle or something) and I wonder if they are doing that because of the rich compensation from the computer? IDK, just spit-balling here lol.

Please Log in or Create an account to join the conversation.

- Monde

-

- Offline

- Elite Member

-

- Posts: 220

- Thank you received: 43

Assuming is never a good thing.

Please Log in or Create an account to join the conversation.

- Paul P.

-

- Offline

- Platinum Member

-

- Posts: 455

- Thank you received: 195

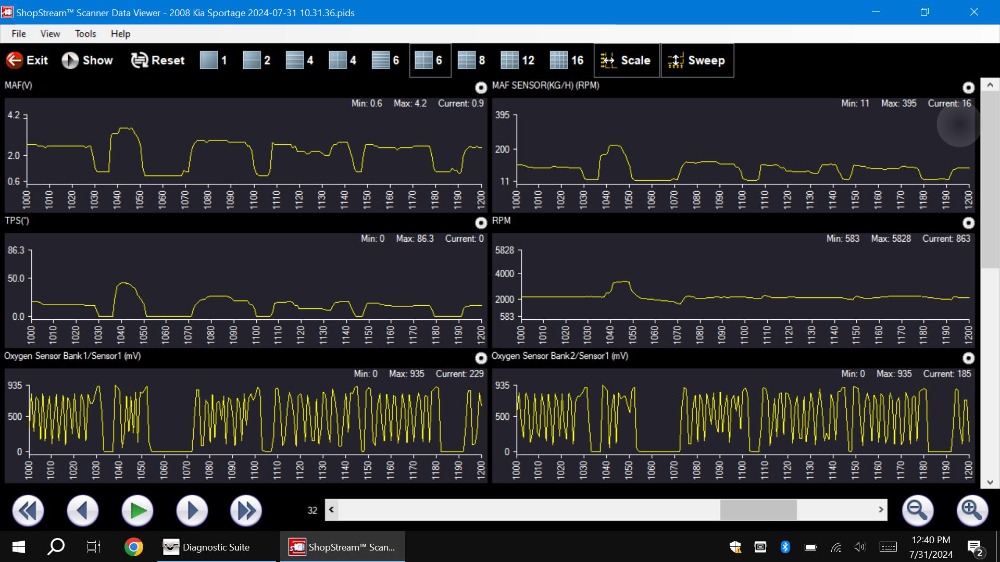

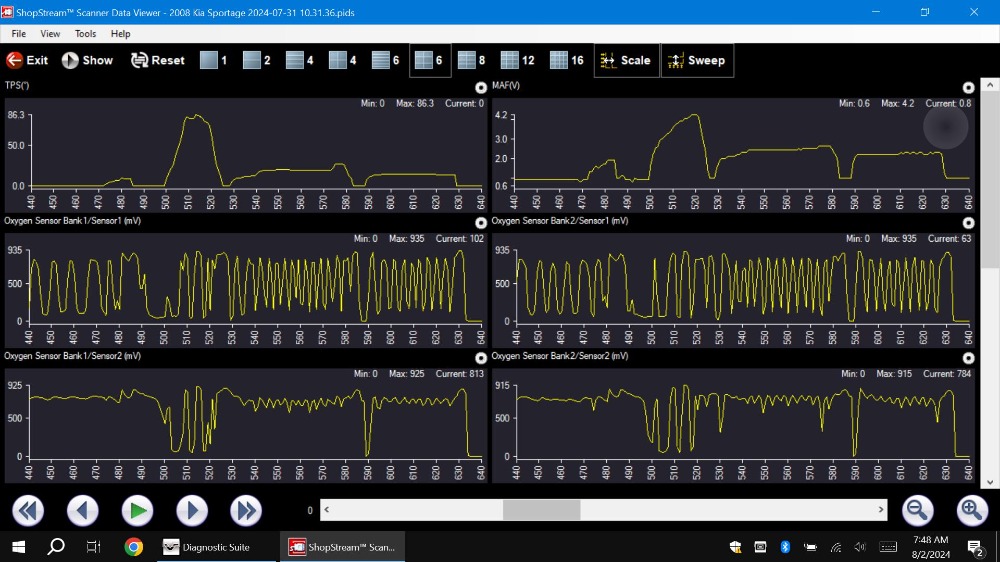

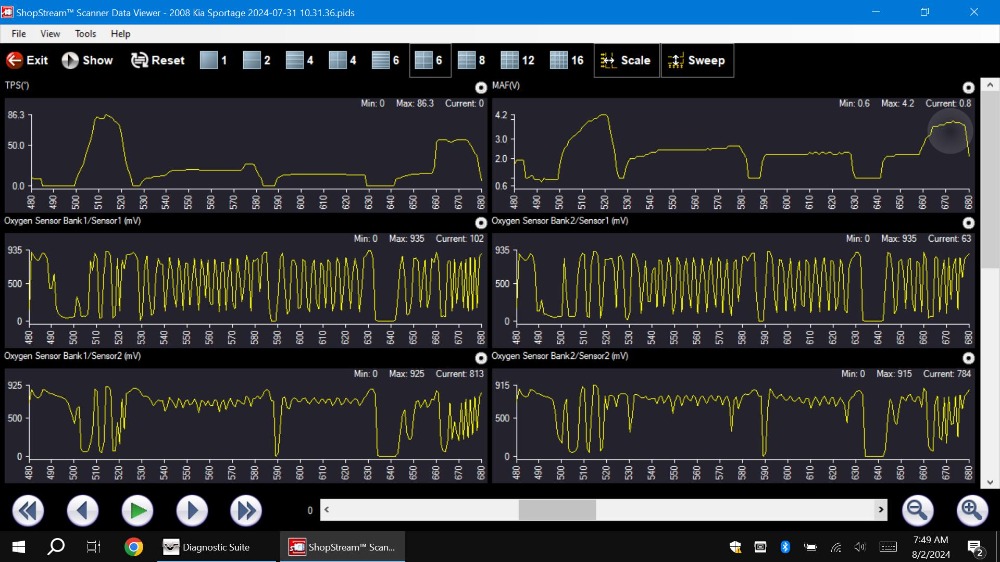

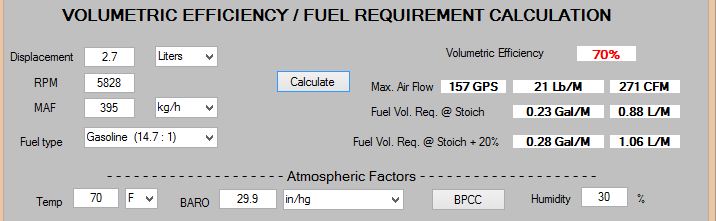

I'd like to point a few things out from the original 7 screenshots of data;

1. It appears that all of the Oxygen sensors are working correctly, they can switch lean/rich and the post sensor's are telling the truth. Feedback System appears good.

2. I see a max of 395 kg/h at an engine speed of 5828 from the Max/Min' this equates to ~110 grams per second

This a low number this engine should be inhaling 150 g/s or 540 kg/h plus!!!

3. The data you have provided is insufficient to properly diagnose this issue because the throttle was only snapped on the drive test. Snap-On frames are 0.1 seconds of real time. We need to get an accurate picture of all engine speeds under load over a longer period of time.

Drive Test

Data Pids of interest;

- ABS LD, which is the Volumetric efficiency of the engine or the Calculated Load

- ABS Throttle Position

- MAF (g/s) or (kg/h)

- Engine RPM

- Actual Equivalence Ratio If the EQ ratio's aren't available graph all 4 O2's, If you are confident there is not a bank to bank difference in the O2's

- Commanded Equivalence Ratio ( Desired) Then just graph one bank, this will speed up data acquisition.

- Long Term Fuel Trim (Both Banks)

- Short Term Fuel Trim (Both Banks)

Data acquisition is key here!!! Bring the vehicle at operating temperature and in Closed loop to a safe area. If it is possible place the Transmission in a lower gear, or you'll have to practice gathering the data with throttle tip in to max RPM from idle without an upshift.

Normally I use generic OBDII data for driveability data acquisition, yes it is slower. Since it looks like the O2's are working Enhanced Data Acquisition is much faster and more data.

You want to see a gradual rise in the TPS all the way to WOT, not just snap throttles. Snap throttles are good for checking Oxygen Storage Capacity of Catalytic Converters.

We really want to see what the fuel trims are doing at all operating speeds of the engine, this is key to this diagnosis.

For example we know that; Fuel trim that is high on the low engine speed, but good at high engine speed is indicative of a vacuum leak.

Fuel Trim that is good at low engine speed, but high on high engine speed is indicative of fuel delivery

Fuel Trim that is high on low and high at high engine speed is indicative of a load sensor.

Fuel Trim that is Negative at low Engine Speed, but Gradually Increases with engine Speed is indicative of a Dirty MAF.

Knowing these four crucial facts is why it is extremely important to acquire "good" data from a gradual increase in engine speed to WOT under load!!!

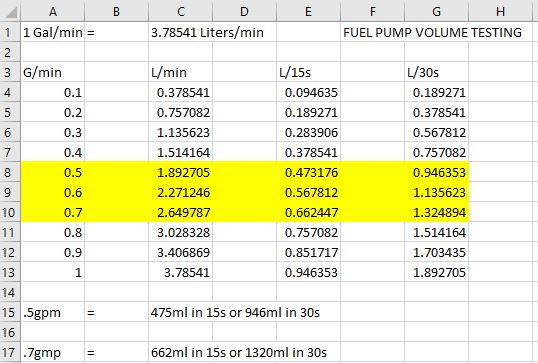

You also mentioned your fuel pressure never dropped out, it is often overlooked to check for fuel quality and VOLUME.

Here is a volume chart i created:

@Monde

Based on the current data set, I would be inclined to say you are right on the money!!!!Next time you get to play with it, increase the rpm to 2 and 3500 and see if the LTFT improve. Also, do a WOT run and see if the calculated load value reaches 90%

The whole point of this drive test is to determine are we dealing with an AIR or Fuel Issue.

When the ABS lD and Calc LD max out, we know the PCM is happy with the amount of air the engine is inhaling; so if there is fuel trim it has to be on the fuel side assuming the feedback system is properly operating.

Hopefully this information can be used to get you headed down of a different path that leads to a resolution for your customer.

Cheers!!!!

Never stop Learning.

Please Log in or Create an account to join the conversation.

- Andrew Parry

-

Topic Author

- Offline

- Junior Member

-

- Posts: 30

- Thank you received: 1

basically, you want me to capture those pids, starting in 1st great, smoothly opening up the throttle and winding out 1st great until WOT. correct?

Please Log in or Create an account to join the conversation.

- Paul P.

-

- Offline

- Platinum Member

-

- Posts: 455

- Thank you received: 195

Not as easy as it sounds it might take a couple of trie, we want to see a data set that goes from idle to WOT with no RPM drop outs, which in some vehicles changes the loop status and definitely no fuel cuts.

Good Luck!!!

Never stop Learning.

Please Log in or Create an account to join the conversation.

- faisalkk

-

- Offline

- New Member

-

- Posts: 16

- Thank you received: 0

Check for any after market parts, which may be ok to look, but may different in diameter or dimensions, causing restricted air flow. Recently watched a video where honey comb grill (don't know exactly what you call it) was missing in front of MAF sensor.

P.s. I am quite new to this field and got a very limited knowledge, Most of knowledge comes from (Scannerdanner & SchrodingersBox videos)

Please Log in or Create an account to join the conversation.