[FIXED] M156 6.2L AMG V8 No Start After Head Gasket Job - Loud Popping In Intake

- abdullah.kose

-

Topic Author

- Offline

- New Member

-

- Posts: 11

- Thank you received: 1

I have a 2008 CLS63 AMG. The car started ticking only for me to find that one of the intake camshafts was severely damaged. I decided to do the intake cams, buckets, and revised headbolts on the car. The headbolts on these engines are problematic. They can fail without much warning and can cause hydrolock under full throttle.

This was done using a procedure previously approved by BMW, where you do headbolts one at a time in order to avoid pulling the head. The job took place in my garage over the course of about two months. It was very much a weekend project thing. I neglected to drain coolant and oil before attempting the job on the left side head. Everything went fine until after a few headbolts were replaced. I loosened one bolt and heard coolant or oil spilling out from the head. I then drained the coolant and oil and continued. I performed the right side head with no coolant or oil in the car. This job required removing all 4 cams and setting the timing and sensor wheel location when I was done.

When the car was all back together I made sure the cylinders were fluid free and it started right up. The car ran and drove fine without any codes for a few slow drives around the neighborhood. As I was on the 3rd mile after the job was complete, the car started smoking and had very light misfires. I suspected some fluid was left on the headgasket from when it drained and ruined the seal when the engine got warm. The car started consuming coolant and smoking even harder. I had to leave it for a while after this. The car never overheated at any point.

When I came back, I pulled the spark plugs and found coolant sitting in the left cylinder head. The right cylinder head was fine. I decided to do the left head gasket.

After another month in the garage, the job was complete. The coolant system holds 20psi all day long and the car passed a compression test with flying colors. The PCV valve connector was damaged and is probably leaking, but I didn't want to wait another week to get the car running. I assembled the car and tried to start it.

The car cranked for a while then made two extremely loud popping noises from the intake manifold area. I was concerned the engine was damaged, so I pulled the plugs and turned it over by hand. The engine was just as smooth turning over as I would expect. It passed another compression test with flying colors.

I found that the left bank of coils was left ungrounded. I screwed that ground down and tried again, only to get the same result. I saw smoke come out of the intake manifold this time. This only happens with injectors plugged in, so I want to avoid cranking with injectors until I see something that tells me to try to start the car again.

I initially thought that the car was firing the coils while fuel was being sprayed into the cylinders. I checked the intake cam signals on both sides and the square wave looks the same on both sides. The signal was very noisy, but the car was cranking. I haven't checked the crank sensor signal, but I never touched that during either job. I am not sure where I would find a known good waveform anyway.

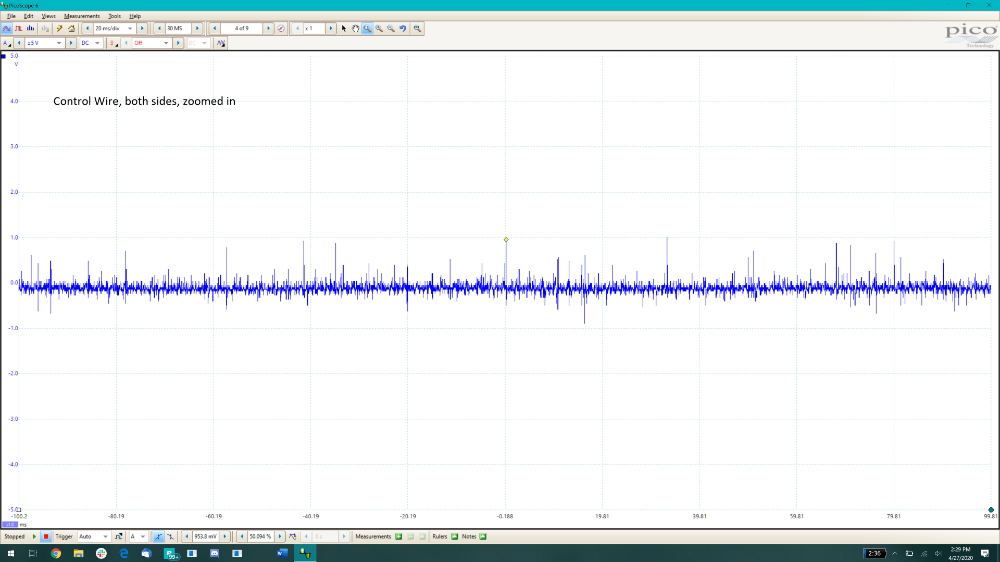

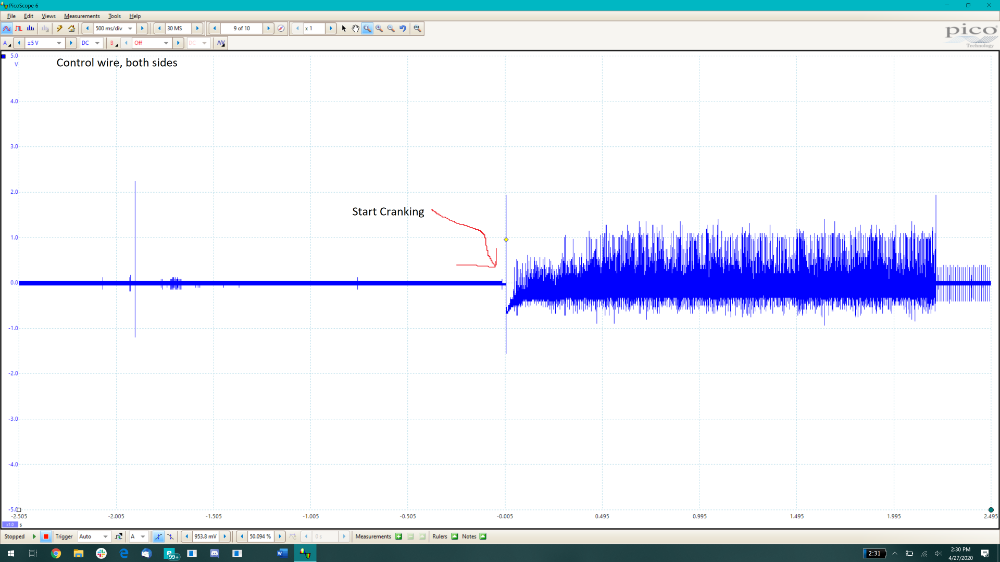

I then checked the four wires on one of the COP ignition coils on the left side to determine if they were firing at even intervals during the crank. The power wire was fine, the ground wire was noisy, the confirmation wire was always 0 volts, and the signal wire was essentially the same signal as the ground wire. I checked a coil on the right side and found the same signals. They're in the images below. I'm assuming that the one unique colored wire on each coil is the control wire from the ecu, and other three are power, ground, and confirmation.

Although I didn't find any strong diagnostic reason to do so, I pulled the fuel rail and injectors out of the manifold and checked for stuck open injectors at the request of someone close to me.

Thankfully nothing on this car is hidden under a manifold. I can probe just about anything you guys would need to see. the crank sensor is a PITA to get to, so I'd rather not probe it, but I can if I have to. The common ground wire for the left side of coils seems too tight to get an amp probe around. The right side seems annoying, but doable. I only have one current clamp and one voltage probe atm, so that is all I can show on the scope atm.

Questions I have yet to answer:

Is ignition timing on these from the intake cam, exhaust cam, or crank sensor? I've only checked intake cams so far.

Will unplugging injectors cause the computer to stop firing the coils?

Is there any point to hooking a test light up to the coil to check for spark when I don't see a control or confirmation signal?

Why would the control wire mirror the signal of the ground wire?

What do I do next?

Note: Everything that could be torqued to factory specs is torqued to factory specs, except the intake manifold, I didn't want to use my new torque to yield bolts until I knew it was running perfectly. The timing tools only fit on the car one way. This has been checked three times now. It is extremely unlikely that the sensor wheel location or the cam timing is the issue.

Please Log in or Create an account to join the conversation.

- abdullah.kose

-

Topic Author

- Offline

- New Member

-

- Posts: 11

- Thank you received: 1

Please Log in or Create an account to join the conversation.

Is ignition timing on these from the intake cam, exhaust cam, or crank sensor? I've only checked intake cams so far.

I'm not sure. And, from browsing Mercedes service information in the past, I'm not sure they'd spell it out for you that way. As far as I'm concerned, your timing looks good. The engine speed and cam position PIDs are giving rational readings. That suggests to me that the PCM is happy with their signals.

Will unplugging injectors cause the computer to stop firing the coils?

Possibly. Do you have current codes for the injector circuits with the injectors unplugged?

A test you could do would be to plug in the injectors, but don't reconnect the fuel pressure line to the rail(s). Or remove the injectors from the rails and plug them into the harness. Run the fuel pressure lines into a bucket, disconnect the pump, or whatever you can to stop fuel spraying everywhere. Clear the codes, crank it and see if spark comes back.

Is there any point to hooking a test light up to the coil to check for spark when I don't see a control or confirmation signal?

Technically no? But I'd probably do it anyway if I were in your shoes. :lol: Always nice to have multiple tests to back up your findings. If you decide to check spark, it may also be a good idea to verify your scope readings with the test light at the coil power/ground circuits.

I could be way off, but I'm reasonably sure that MB doesn't use a confirmation signal on their four wire coils. Pretty sure it's like other German makes, which actually use that fourth wire as another ground.

Why would the control wire mirror the signal of the ground wire?

It's not really a signal you're looking at, just noise coming off the block during cranking. There'a a lot of current going through the engine at that point, and other circuits are gonna pick up some of that interference. The same kind of noise can be seen in the coil power capture. I wouldn't read too much into it just yet.

You can also end up seeing that kind of noise just from your scope leads. ESPECIALLY on a Pico with the sensitivity turned up.

What do I do next?

I like the injector idea above.

Please Log in or Create an account to join the conversation.

- abdullah.kose

-

Topic Author

- Offline

- New Member

-

- Posts: 11

- Thank you received: 1

Please Log in or Create an account to join the conversation.

- abdullah.kose

-

Topic Author

- Offline

- New Member

-

- Posts: 11

- Thank you received: 1

About the squirting: it was oil. When the headgasket blew last time, coolant mixed with the oil and got past the PCV. It let a ton of coolant and oil in the manifold. I let it drain while I did the job, but there is still a lot in there I guess. I have no idea why it waited for me to test 7 cylinders before drawing oil in. I highly doubt that the cylinder pulled enough vacuum to pull oil from the head gasket with no spark plug installed, so I think the manifold is the only place it could come from. my next step is to pull the manifold and see how much oil is sitting in there with my boroscope. I won't do anything else with spark until I do that - my biggest goal here is to avoid damaging anything.

I've attached pictures of what I see on the control wires. They're all the same except for that 7th one. I neglected to save that waveform, but it is very similar. The squares are just closer. I'll investigate more when I can. I haven't checked to make sure the coils are all working, just that they're being commanded on so far.

Questions:

Is it possible for a 4 wire coil to just go haywire and fire when it wants to, even if there isn't input from the computer?

Is it possible for a coil to delay firing for a long time after being commanded on? I wouldn't think so, but I don't know what I don't know.

Would you guys recommend that I do something other than pull the manifold? I did a compression test on that cylinder before the squirt happened today and it passed again with flying colors.

Thanks,

Abdullah

Please Log in or Create an account to join the conversation.

- abdullah.kose

-

Topic Author

- Offline

- New Member

-

- Posts: 11

- Thank you received: 1

I'm not sure when I'll have time to put this back on, but I'll make sure to update the thread when I do.

-Abdullah

Please Log in or Create an account to join the conversation.

abdullah.kose wrote: Is it possible for a 4 wire coil to just go haywire and fire when it wants to, even if there isn't input from the computer?

Possible, but unlikely. The only way this would happen is if the control wire was intermittently shorted to power.

Remember, the coil signal you're seeing on the scope isn't just a suggestion from the PCM.

You're left with the PCM doing what it's programmed to do based on its inputs, OR an intermittent short to voltage on the control wire. I can count on one hand the number of times I've seen an intermittent short to power.

Is it possible for a coil to delay firing for a long time after being commanded on? I wouldn't think so, but I don't know what I don't know.

Also unlikely, IMO. I'd suspect that the difference you saw between cylinders may be down to engine cranking speed, or possibly changes in battery voltage between tests.

I watched them fire outside and the spray pattern was what I would expect. No crazy flow or anything. I started checking all the coils for control and started seeing the square wave I expected.

Interesting! So do you believe that the square wave for coil control only came back after electrically reconnecting the injectors?

I can't say I've ever tried disconnecting an injector on a MB then checked to see if spark came or went on the same cylinder. Might be valuable for future diagnostics...

Please Log in or Create an account to join the conversation.

- abdullah.kose

-

Topic Author

- Offline

- New Member

-

- Posts: 11

- Thank you received: 1

Sorry for the late reply, but yes, I believe that coil control disappears when all the injectors are unplugged. I never tried unplugging a single injector and checking control on a single cylinder. It was all or nothing for fuel. I always checked continuity between my t pin and the connector end to make sure I wasn't missing the signal entirely. I am very confident the scope result is valid. I'll make sure to check the injector circuit first if I ever come across another m156 ignition control issue.

I finally managed to put this thing back together and start it up. I installed a new PCV valve in case that was somehow failing and still letting oil in. The hold down connector was broken on one end so it needed replacing anyway. I rotated the engine to bdc on each pair of pistons and checked to make sure there was no oil in each cylinder. I then cranked it without spark plugs installed and checked to make sure oil didn't come in again.

I then repeated the test I did earlier on the last two coil control wires. I saw consistent timing on the square waves that popped up as as I heard the air compress in the cylinder. It was the same 670ms or so as earlier while cranking with only one plug installed. I checked for excessive fuel spray again (I'm terrified of hydrolocking this thing) before putting it all back together and turning the key. It smoked a bit on startup, but that soon went away. I let it sit idling for over 25 minutes until I was satisfied that there was no smoke coming out of the tail pipe. This was far longer than it took for the car to smoke the first time around. No overheating or anything this time.

I don't really know for sure what fixed the issue. I suspect a two things though. Some coil connections were soaked in oil for a while because they sit below where oil drips from the valve cover area. Maybe that was shorting the control signal high somehow. I never cleaned them because I wanted to see the issue happen on the scope if that was the case. Maybe the oil dripped out in the silly amount of time it has taken me to get back to this.

There was definitely a liquid oil coolant mix in the manifold before I rebuilt it. I cleaned it out and replaced the pcv valve to make sure it wouldn't happen again. Oil in the intake manifold is a terrible thing for the car, but how would that cause popping?

I didn't really touch anything else. Maybe I'll never know what finally fixed it.

Thank you for your help. Talking through these ideas really helped me get my plan in order and think through the issues. I'm not sure what I would have done if I hadn't learned the 3/4 wire coil stuff from here too.

Best,

Abdullah

Please Log in or Create an account to join the conversation.

Definitely good to know about the injectors and the coil output signal. I've known other makes to eventually turn off an injector in response to a dead misfire, but never seen one disable spark immediately in response to an injector circuit fault. That's an aggressive intentional shutdown strategy. :ohmy:

I didn't really touch anything else. Maybe I'll never know what finally fixed it.

Thank you for your help. Talking through these ideas really helped me get my plan in order and think through the issues.

Sometimes that's all you need. :silly: I'll do the same with coworkers. Perspective can definitely help with complex issues.

Please Log in or Create an account to join the conversation.