*** Restricting New Posts to SD Premium Members ONLY *** (09 May 2025)

Just made a new account? Can't post? Click above.

Passive waveform modulation ? Trying again

- paul.simpson

-

Topic Author

Topic Author

- Offline

- Senior Member

-

- Fat fingers and small kèypads don't get on

- Posts: 47

- Thank you received: 1

I'm working on a X type 2006 jaguar 2.0 diesel , service complete except after the fuel filter change it proved to be a pain to bleed the system . Finally i found out that the push connectors to the filter and pump the o rings were not making a seal . Hence the amount of air that got into system. I am now satisfied that i have all the air out, I had to subistute a pipe for a clear one to monitor the bleeding .

The problem is I can not get it to start easy and when it does its rough. I know the fuel rail pressure was pushing out 58200 kpa, something I check before any diesel filter change, pass experience told me to tell the customer first if it's low and this could be a separate issue, before I started to work on it.. now it just barely gets up to 14000.

My fault codes are P1211 and P0251.

This why I've hooked up to this channel , I am not really confident to start back probing , and the po251 relates to the fuel metering sensor on the back of the fuel pump. I need to know please the correct way of testing this, it has two wires, one goes to F20 in the fuse box and the other is and an output to ecm. The electrical drawings states that the output to the ecm is pwm . ( has the title " subject " states )

Can someone direct me in the right direction or am I confusing the issue or can i treat the sensor like and other.

Hope you can understand all this.

Oh I did change the injectors because the bleed off test was really excessive... and it a had a new fuel pump some 8 months back.

Thanks

Please Log in or Create an account to join the conversation.

- paul.simpson

-

Topic Author

Topic Author

- Offline

- Senior Member

-

- Fat fingers and small kèypads don't get on

- Posts: 47

- Thank you received: 1

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4947

- Thank you received: 1102

As far as diesel's, we just don't have many diesel powered passenger cars in the States, aside from a handful of imports. I can't think of a single USDM diesel powered passenger car.

Fortunately, there's a large community abroad who will hopefully be able to help you out with this one.

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6053

- Thank you received: 1523

paul.simpson wrote: Hi, is the word diesel a bad word here.

:lol: Nope! But, we are somewhat limited by information availability. Like in this case, they sell the X-Type in North America, but only with the 3.0L engine

Just so I have the correct context, are you looking at solenoid on the high pressure fuel pump? And, is this fuel metering sensor looking at high side rail pressure?

The control of the pump solenoid sounds like a conventional ground side output, given that it has a fused power supply, and that the other wire goes to the computer. You could easily test this circuit with a test light or a DVOM. See this video for a good example:

The catch is that I don't know if the solenoid is normally open (the pump defaults to max pressure) or normally closed (the pump defaults to zero pressure). That makes diagnosing the operation of this solenoid tricky - does the PCM run the solenoid to lower pressure, or increase it? :blink:

Are there three wires going to this fuel metering sensor? If so, then I think you're correct in treating it like any other pressure sensor.

For my reference, does this system use a low pressure lift pump, or does it rely on high pressure suction to get fuel from the tank?

Please Log in or Create an account to join the conversation.

- paul.simpson

-

Topic Author

Topic Author

- Offline

- Senior Member

-

- Fat fingers and small kèypads don't get on

- Posts: 47

- Thank you received: 1

Yes the solenoid is on the high pressure fuel pump, it feeds direct to the fuel rail where a 5v pressure sensor tells the ecm to control the high pressure solenoid on the pump.

The hp solenoid, I read, is normally open , but not much info on that, I need to investigate further on this issue.

The pump relies on high pressure suction to get fuel from the tank.

The solenoid is passive waveform modulation, so I assume ( hate that word ) this means it moves in and out to regulate the pressure feed.

So my question is how to test this solenoid and what type of wave do I look for on the scope. Taking Into account it's safe to back probe this solenoid safely.

Please Log in or Create an account to join the conversation.

- steve

-

- Offline

- Junior Member

-

- Posts: 32

- Thank you received: 17

It controls the flow on the inlet side of the pump and is normally open

A good test of the pump is to disconnect the imv and the injectors then crank the engine

This will force to pump to produce its maximum pressure which should be over 1000 bar

You can safely back probe the imv and it's ground side switched

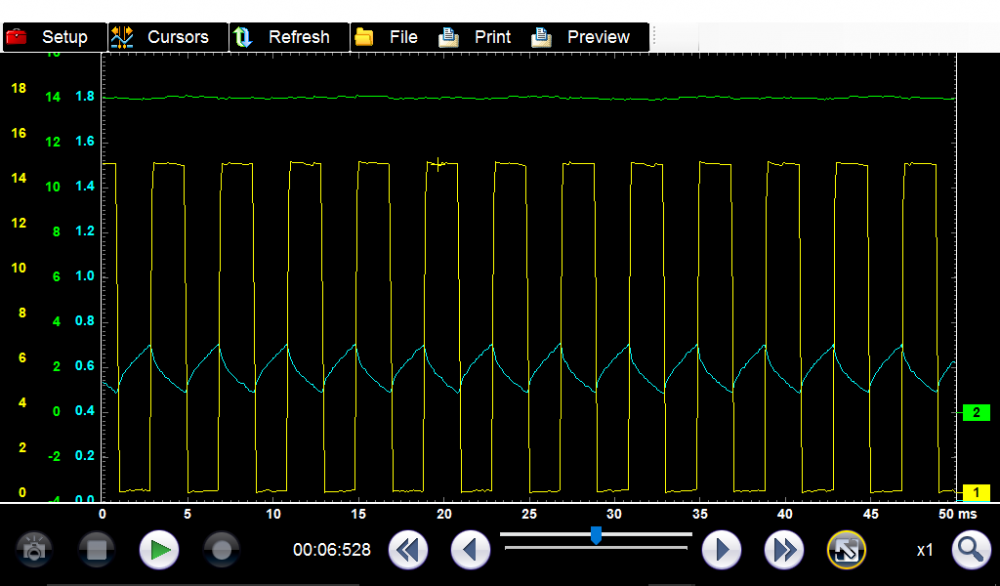

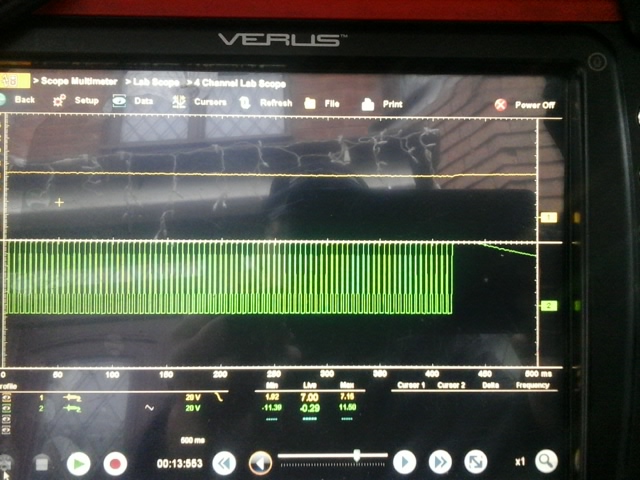

This image is off a Vauxhall but same principal

Please Log in or Create an account to join the conversation.

- Andy.MacFadyen

-

- Offline

- Moderator

-

- Posts: 3353

- Thank you received: 1037

" We're trying to plug a hole in the universe, what are you doing ?. "

(Walter Bishop Fringe TV show)

Please Log in or Create an account to join the conversation.

- paul.simpson

-

Topic Author

Topic Author

- Offline

- Senior Member

-

- Fat fingers and small kèypads don't get on

- Posts: 47

- Thank you received: 1

I'm on it today and putting to test

Big thank you.

Please Log in or Create an account to join the conversation.

- paul.simpson

-

Topic Author

Topic Author

- Offline

- Senior Member

-

- Fat fingers and small kèypads don't get on

- Posts: 47

- Thank you received: 1

Please Log in or Create an account to join the conversation.

- Richey.brown

-

- Offline

- Junior Member

-

- Posts: 38

- Thank you received: 6

Please Log in or Create an account to join the conversation.

- paul.simpson

-

Topic Author

Topic Author

- Offline

- Senior Member

-

- Fat fingers and small kèypads don't get on

- Posts: 47

- Thank you received: 1

All the pipes to the feed and return have been substitute for new clear fuel noses and secure fasteners, because as you stated air leaks, where found all over prior. Now I can see the flow and return , and I am happy that this problem is good.

The injectors are brand new from a delphi agent who have a inpecable reputation. But I will do another bleed off test.

The compression is excellent .

The timing as been checked .

I think now , that the Imv maybe not opening or closing properly causing irrational low fuel pressures . The egr was blocked off from the exhaust in feed end with a small plate made for this purpose , its a cheap alternative to removing the whole egr unit, the test made no difference

My fault code mention imv malfunction so my concern was why it showed 7 volts, even if it was a known good competent should read 12v ?

Further test will be Carried out on thrusday. No time tomorrow so will report later thanks for your advice.

Please Log in or Create an account to join the conversation.

- paul.simpson

-

Topic Author

Topic Author

- Offline

- Senior Member

-

- Fat fingers and small kèypads don't get on

- Posts: 47

- Thank you received: 1

I've uploaded a scope pic but not all the screen is showing , i must get a better frame size . Not the best scope set up. I'm still learning it.

Please Log in or Create an account to join the conversation.

- steve

-

- Offline

- Junior Member

-

- Posts: 32

- Thank you received: 17

paul.simpson wrote: My fault code mention imv malfunction so my concern was why it showed 7 volts, even if it was a known good competent should read 12v ?

That would be a concern but looking at the image you have 11 volts on the control wire so it doesn't make sense

I would double check but only use one channel at at time as if you cross the pins by double probing you can damage the ecu

Also in the image it's looks like your ac coupled on the second channel

Try just using one channel on the control wire, drop your time base to 50ms to give more detail, use a 20v scale and make sure it's not ac coupled

The top of the square wave will show you the source voltage and will also be on the maximum voltage reading below

Having said all that you might find it's air or a leak in the system that's causing the fault code as Richey says that's more common

If you subscribe to premium Paul has a good case study on a Pontiac and how performance related fault codes can throw you

Please Log in or Create an account to join the conversation.

- paul.simpson

-

Topic Author

Topic Author

- Offline

- Senior Member

-

- Fat fingers and small kèypads don't get on

- Posts: 47

- Thank you received: 1

im back on this x type diesel need to pick your brains if thats ok,

Played on my mind about this air leakage and the 7 volt imv.

So i looked into the air first and notice over night , the next morning the supply pipe from the filter to pump there is a 4inch air space, so theres a problem there.

My concern about the imv measuring 7volts was really bugging me , when un plugged read 12v, the test data mentioned while idleing should read 10.5v to 11v.

Because this thing will not start i only had cranking to rely on.

Any way i opted for a new imv and this tested to be a lot better in that there is12v plugged and unplugged and at cranking 11.0v. BUT ...still no start. So back on the air leakage.

Im still trying to find out where and how this air can be leaking in, but my question to you is, while going under the assumption that the air leak was cured,, can cranking and cranking destory a new pump, the reason. Because i did another bleed off test, hardly anything came out 1mm if that , across the board.

The fuel pressure was very low 4000 kpa and when imv and injector electrical connectors disconnected went to 14.000 kpa. Sorry about the kpa reaading but my scanner wont switch to psi or bar , it keeps going back to kpa, this issue is with snapon.

So do you think its possible that not having the fuel pump not properly primed all the time , would kill it. Or once this air problem is cured, will the pressure build back up ?

I must say when cranking there seems to be no air coming in, but as i mentioned over night standing proves different.

I am now looking for some new softer clear fuel pipe to make hopefully an air tight connection.

The clear with braided string like stuff im using now after a time goes hard and may not be suitable.

Thanks inadvance for your time.

Please Log in or Create an account to join the conversation.

- Richey.brown

-

- Offline

- Junior Member

-

- Posts: 38

- Thank you received: 6

Please Log in or Create an account to join the conversation.

- paul.simpson

-

Topic Author

Topic Author

- Offline

- Senior Member

-

- Fat fingers and small kèypads don't get on

- Posts: 47

- Thank you received: 1

As for the air and cranking issue i was refereing to all the cranking done pior to finding it was sucking in air. So you still think it wont be affected ?.

Please Log in or Create an account to join the conversation.

- Richey.brown

-

- Offline

- Junior Member

-

- Posts: 38

- Thank you received: 6

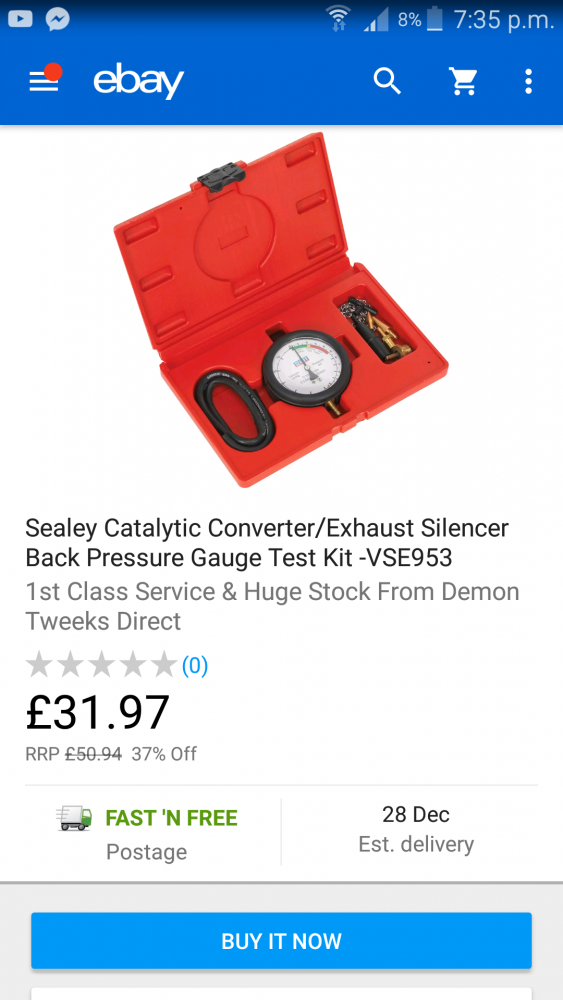

If all is good then watch this to help with the pre supply system

You don't need the "Sight glass" in the video the clear pipe and a cheap positive and negative pressure gauge work fine. Look at this on eBay

Please Log in or Create an account to join the conversation.

- Richey.brown

-

- Offline

- Junior Member

-

- Posts: 38

- Thank you received: 6

Please Log in or Create an account to join the conversation.

- Richey.brown

-

- Offline

- Junior Member

-

- Posts: 38

- Thank you received: 6

Please Log in or Create an account to join the conversation.