Help us help you. By posting the year, make, model and engine near the beginning of your help request, followed by the symptoms (no start, high idle, misfire etc.) Along with any prevalent Diagnostic Trouble Codes, aka DTCs, other forum members will be able to help you get to a solution more quickly and easily!

Opinions/suggestions on how to proceed based on this relative compression grab

- BLWelch94

-

Topic Author

- Offline

- New Member

-

- Brandon

Less

More

- Posts: 7

- Thank you received: 1

3 months 1 week ago #92261

by BLWelch94

Opinions/suggestions on how to proceed based on this relative compression grab was created by BLWelch94

1997 Chevrolet K1500 5.7 4L60 Transmission Extended Cab Long Box

Engine MIL On - harsh/roughness to the idle, lack of power/sluggish, when accelerating heavy fuel smell from exhaust.

History: Sat for 4 almost 5 years barely used due to a run problem, I purchased the vehicle found the injector assembly to be at fault and recall specifically cylinder 5 to be constantly missing. Replaced the assembly then would misfire some still after hot found fuel rail pressure below specification, found the fuel pump output to be insufficient and verified power and grounds were ok via load test and amperage measurement. Replaced fuel pump and filter at this point due to that the vehicle had a P0430 DTC present but I did not have the means to address this financially at the time, because while dealing with this misfire there was also a power steering leak to address and due to age and sitting I went ahead and replaced cap, rotor, plugs, and wires. Aside from the light on it seemed ok.

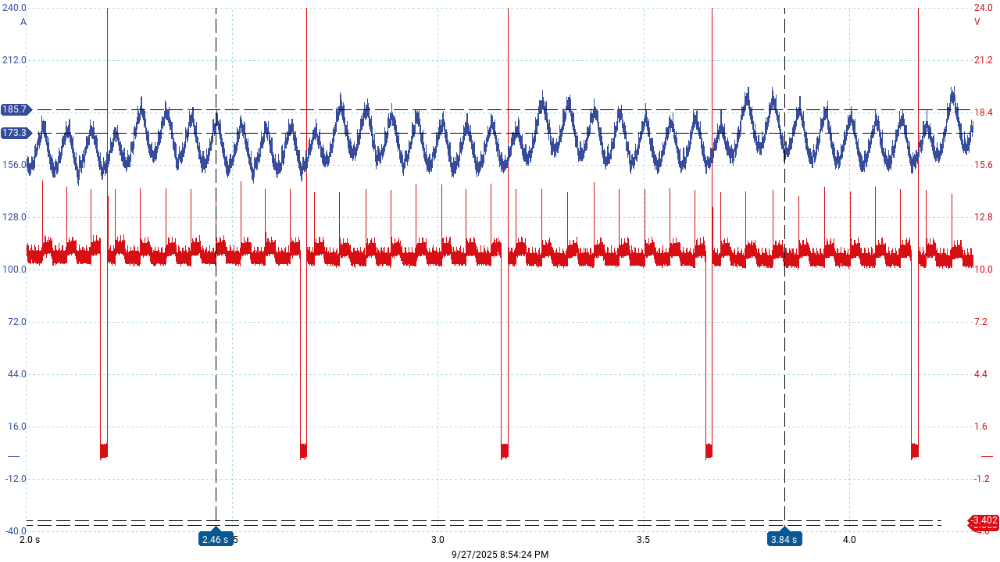

Fast forward to last November 2024 and I blew an oil cooler line early one morning, managed to shut it down and get that repaired but ever since it hasn't seemed right and lately since summer 2025, I began noticing this rough idle etc. Connected scan tool (topdon phoenix nano) and only DTC of note was still the P0430 misfire monitor showed slow active counter on cylinder 4, history showed over 2,000 counts on 4 and around 200 counts on 5. Given my oil out incident I pulled the plug, verified it looked ok, gap was right and pulled compression on that cylinder and had around 145-150psi all 3 times I checked. A couple days later I compared and swapped #4  spark plugs because the burn pattern on #4 just seemed peculiar maybe a little too clean for lack of finding the right words and before I even started the truck, I pulled back up misfire data and noticed no history misfires on #4 now I have the same theme on #5 . Now come this evening and I went back to basics of sorts and pulled a relative compression with a fully charged battery and got what I feel is a peculiar pattern, I've formed a habit of doing REL COMP on every misfire before I get too deep and have seen a variety of patterns but none such as this then again Im not typically pulling them on old small block chevy's.

I would love to hear people's analysis of the waveform which I have saved in a few formats as well as what your next step in the diagnostic process would be if this was yours to solve!

Engine MIL On - harsh/roughness to the idle, lack of power/sluggish, when accelerating heavy fuel smell from exhaust.

History: Sat for 4 almost 5 years barely used due to a run problem, I purchased the vehicle found the injector assembly to be at fault and recall specifically cylinder 5 to be constantly missing. Replaced the assembly then would misfire some still after hot found fuel rail pressure below specification, found the fuel pump output to be insufficient and verified power and grounds were ok via load test and amperage measurement. Replaced fuel pump and filter at this point due to that the vehicle had a P0430 DTC present but I did not have the means to address this financially at the time, because while dealing with this misfire there was also a power steering leak to address and due to age and sitting I went ahead and replaced cap, rotor, plugs, and wires. Aside from the light on it seemed ok.

Fast forward to last November 2024 and I blew an oil cooler line early one morning, managed to shut it down and get that repaired but ever since it hasn't seemed right and lately since summer 2025, I began noticing this rough idle etc. Connected scan tool (topdon phoenix nano) and only DTC of note was still the P0430 misfire monitor showed slow active counter on cylinder 4, history showed over 2,000 counts on 4 and around 200 counts on 5. Given my oil out incident I pulled the plug, verified it looked ok, gap was right and pulled compression on that cylinder and had around 145-150psi all 3 times I checked. A couple days later I compared and swapped #4  spark plugs because the burn pattern on #4 just seemed peculiar maybe a little too clean for lack of finding the right words and before I even started the truck, I pulled back up misfire data and noticed no history misfires on #4 now I have the same theme on #5 . Now come this evening and I went back to basics of sorts and pulled a relative compression with a fully charged battery and got what I feel is a peculiar pattern, I've formed a habit of doing REL COMP on every misfire before I get too deep and have seen a variety of patterns but none such as this then again Im not typically pulling them on old small block chevy's.

I would love to hear people's analysis of the waveform which I have saved in a few formats as well as what your next step in the diagnostic process would be if this was yours to solve!

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

Less

More

- Posts: 4957

- Thank you received: 1111

3 months 1 week ago #92262

by Noah

"Ground cannot be checked with a 10mm socket"

Replied by Noah on topic Opinions/suggestions on how to proceed based on this relative compression grab

I see that kind of "rolling" pattern sometimes. When there is a cylinder with with lower compression, the next peak in the firing order will be higher and the pattern will kind of march down like that.

I don't like to measure compression with a gauge on just a single cylinder, "good" compression is more than a single measurement, compression really needs to be compared across all cylinders to make sure they contribute evenly. I would probably disable fuel delivery, perform a compression test with all the plugs removed, and repeat the test with a squirt of oil in the cylinders that may come up low since you mentioned heavy fuel smell, just to hopefully eliminate fuel wash as a cause of potential low compression.

I would probably also run the scan tool injector balance test, and make sure that the injectors, regulator and fuel pump check valve are capable of maintaining engine off fuel pressure.

You said "the only code of note" was a cat efficiency code. That sounds like there are possibly more codes stored?

I don't like to measure compression with a gauge on just a single cylinder, "good" compression is more than a single measurement, compression really needs to be compared across all cylinders to make sure they contribute evenly. I would probably disable fuel delivery, perform a compression test with all the plugs removed, and repeat the test with a squirt of oil in the cylinders that may come up low since you mentioned heavy fuel smell, just to hopefully eliminate fuel wash as a cause of potential low compression.

I would probably also run the scan tool injector balance test, and make sure that the injectors, regulator and fuel pump check valve are capable of maintaining engine off fuel pressure.

You said "the only code of note" was a cat efficiency code. That sounds like there are possibly more codes stored?

"Ground cannot be checked with a 10mm socket"

The following user(s) said Thank You: BLWelch94

Please Log in or Create an account to join the conversation.

- BLWelch94

-

Topic Author

- Offline

- New Member

-

- Brandon

Less

More

- Posts: 7

- Thank you received: 1

3 months 5 days ago #92277

by BLWelch94

Replied by BLWelch94 on topic Opinions/suggestions on how to proceed based on this relative compression grab

Regarding DTC's the following 3 are what is present.

1) P0300 "Engine Misfire Detected"

2) P0430 Catalyst System Low Efficiency Bank 2

3) P1351 Instrument Cluster (IC) Output High/Pulse Detected When GND_Cylinder 1

These are as they appear in the topdon phoenix nano.

For P1351 GM service information offers a different description, "Ignition Coil Control Circuit High Voltage" is the OEM code description.

I have not yet had a chance to perform a proper compression and cylinder leak down test, I realize this additional DTC may point me in a different direction and my compression issue may be cylinder wash from fuel due to spark related concerns based on looking at DTC descriptor but have not yet dove into the information and testing for this and again given my oil out concern I for my own comfort am wanting to verify proper compression and acceptable leak down on all cylinders before venturing further. I will post updates as my diagnosis progresses and provide as much information as possible. Also, the vin for my truck is 1GCEK19R4VE183338 for reference.

1) P0300 "Engine Misfire Detected"

2) P0430 Catalyst System Low Efficiency Bank 2

3) P1351 Instrument Cluster (IC) Output High/Pulse Detected When GND_Cylinder 1

These are as they appear in the topdon phoenix nano.

For P1351 GM service information offers a different description, "Ignition Coil Control Circuit High Voltage" is the OEM code description.

I have not yet had a chance to perform a proper compression and cylinder leak down test, I realize this additional DTC may point me in a different direction and my compression issue may be cylinder wash from fuel due to spark related concerns based on looking at DTC descriptor but have not yet dove into the information and testing for this and again given my oil out concern I for my own comfort am wanting to verify proper compression and acceptable leak down on all cylinders before venturing further. I will post updates as my diagnosis progresses and provide as much information as possible. Also, the vin for my truck is 1GCEK19R4VE183338 for reference.

Please Log in or Create an account to join the conversation.

- BLWelch94

-

Topic Author

- Offline

- New Member

-

- Brandon

Less

More

- Posts: 7

- Thank you received: 1

3 months 4 days ago #92283

by BLWelch94

Replied by BLWelch94 on topic Opinions/suggestions on how to proceed based on this relative compression grab

Compression and leak down test results:

1 - 145psi / 1%

2 - 145psi / 0%

3 - 140psi / 7%

4 - 143psi / 11%

5 - 142psi / 2%

6 - 125psi / 40%

7 - 145psi / 0%

8 - 140psi / 0%

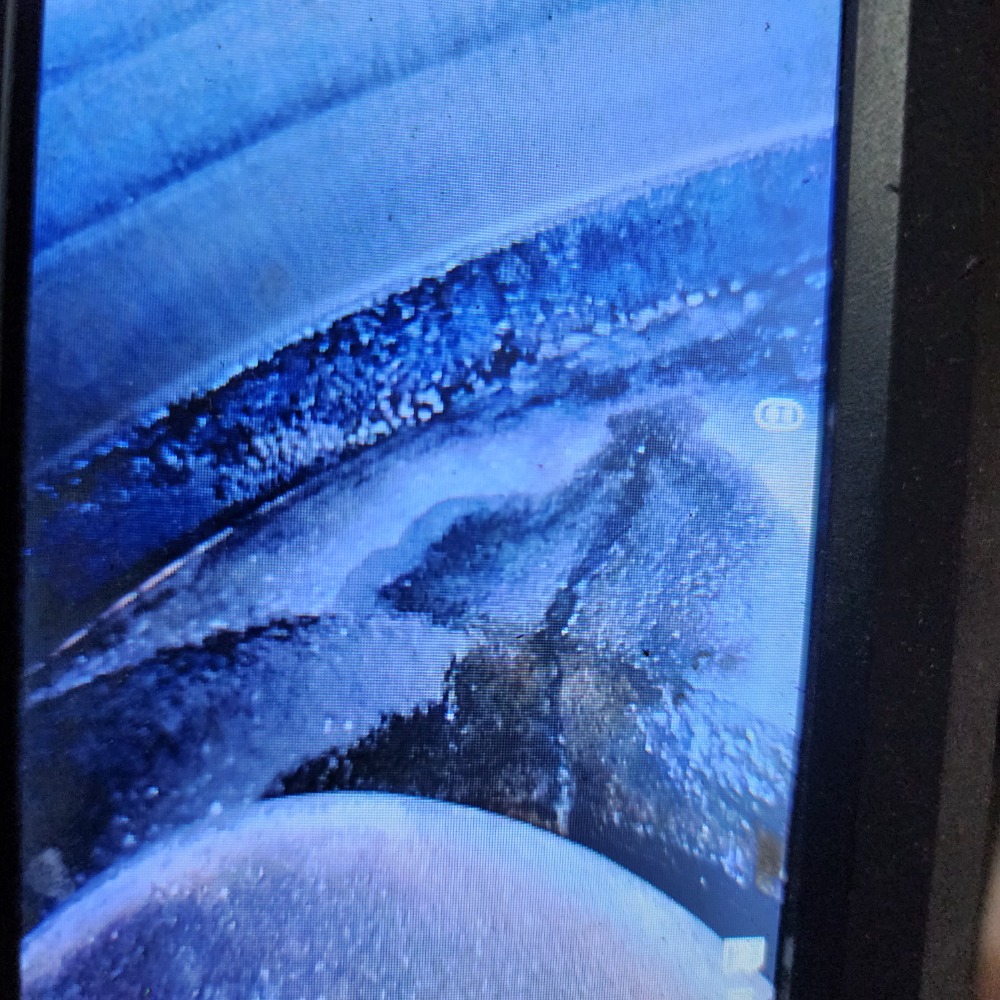

Further inspection I found the cooling system pressurizing and when I removed the radiator cap it was pushing coolant out with small bubbles. I removed the leak down tester and installed a cooling system pressure tester and used a borescope to inspect the cylinder, it appears I have a cracked cylinder head on cylinder #6 and on with pressure applied to the cooling system I was able to see the wetness around the suspected crack grow.

1 - 145psi / 1%

2 - 145psi / 0%

3 - 140psi / 7%

4 - 143psi / 11%

5 - 142psi / 2%

6 - 125psi / 40%

7 - 145psi / 0%

8 - 140psi / 0%

Further inspection I found the cooling system pressurizing and when I removed the radiator cap it was pushing coolant out with small bubbles. I removed the leak down tester and installed a cooling system pressure tester and used a borescope to inspect the cylinder, it appears I have a cracked cylinder head on cylinder #6 and on with pressure applied to the cooling system I was able to see the wetness around the suspected crack grow.

The following user(s) said Thank You: Noah

Please Log in or Create an account to join the conversation.

- BLWelch94

-

Topic Author

- Offline

- New Member

-

- Brandon

Less

More

- Posts: 7

- Thank you received: 1

3 months 3 days ago #92287

by BLWelch94

Replied by BLWelch94 on topic Opinions/suggestions on how to proceed based on this relative compression grab

#6 exhaust port

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

Less

More

- Posts: 4957

- Thank you received: 1111

3 months 1 day ago #92289

by Noah

"Ground cannot be checked with a 10mm socket"

Replied by Noah on topic Opinions/suggestions on how to proceed based on this relative compression grab

Bad news, at least you know what you're up against. Nice job sticking with it and finding the issue.

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

Time to create page: 0.305 seconds