2013 Yukon Denali XL 1500 6.2 overcharging

- jd64

-

Topic Author

- Offline

- New Member

-

- Posts: 17

- Thank you received: 1

2013 Denali is cutting my tail! This is the father in law's car, came to me with a belt squeak and loosing coolant.

Summarized History:

Water pump, Radiator, heater hose, Tee fitting later no leaks under 20lbs of pressure.

Drive the 1st time 30F outside get the running hot turn off AC pop up with MIL.

Finger in coolant test and is not even hot,

Replace the ECT, still having issue

Vacuum the coolant system, refill and good.

Side note start

While troubleshooting and pulling codes noticed the system was charging 15+v and after research found it was normal for this vehicle or thought to be.

Also notice only a few min of ignition on not running, message of low battery to start engine.

Rigged a digital voltmeter for the cigarette lighter/12v outlet.

Coolant system still good.

Removed the ESM and put it back.

Some of this testing did without driving lights, wipers, AC or rear defrost on.

Found a short on a wire connecting to under hood fuse box and repaired

Side not stop

Still have the squeaking issue to resolve.....notice belt squeak is after sitting for 12+hrs.

Replace belt and tensioner and squeak went away only to return the next day.

Turns out the battery is over 5yrs old and doesn't hold it's charge as it should but also parts of the onboard systems are not reading the same.

Voltmeter at the battery and the voltmeter in the 12v outlet are within .2v and scan tool within .5v of them both.

The dash voltmeter is about 1.2v off and know they are not 100%

Battery changed and still the same thing minus how quick the dash notice bat low start engine appears

Cold start, alt signal unplugged, no squeak and 13.8v (as it should default to).

Replace the alternator still same thing.

Replace the battery current sensor.

Find ScannerDanner and multiple videos ect

Go to return the alternator and put the original back on BUT is smells burnt!

Leave the new one and start digging in.

Found the negative terminal was creating resistance and replaced just the terminal via cut/replace.

Started doing some tracing and all the sensors I tested had a 5v ref but found the scan tool showed that ignition voltages were different,

Found that the 5v ref via circuit 530 from BCM to ignition had a good 5v reference with the switch off and system awake and when the switch is in the first click/acc of the switch.

When in the run position it drops to 4v, while cranking goes up a little and with engine running 4v which is in line with the difference I am seeing on the scan tool.

Start probing the actual ignition switch and find the same results, replace it with same results. (killed my scan tool cause I acidentaly shorted across the switch, blew the DLIS fuse and kill the tool connected via OBDII DLC)

Using the Autel AL539b and another cheap oscope found the PWM signal is not 120hz but more like 96hz

The signal seems to respond the same when tested at BCM, Batt Current Sensor and at altenator

Found using the xtool old and new the Electronic Suspension Module becomes unresponsive more times than providing data

Found that it seems there is a ghost frequency found at the under hood fuse box which I think is related probing the side of some of the fuse connector it shows a small amount of voltage with a signal

Found using the xtool to set the duty cycle of the alternator it responds and will stay set for a while then slowly starts to climb.

The xtool also shows the desired voltage is less than the current voltage

Know I have did way more than listed here and probably forgot to list some of the important testing I have already done.

Help me wise ones!!!!!!

Please Log in or Create an account to join the conversation.

- ferris48

-

- Offline

- Premium Member

-

- Posts: 129

- Thank you received: 47

I would investigate the power feeds to the cluster first, then the bcm, for a voltage drop.The dash voltmeter is about 1.2v off

Please Log in or Create an account to join the conversation.

- ferris48

-

- Offline

- Premium Member

-

- Posts: 129

- Thank you received: 47

This IPC fuse 46 is interesting. If you have 15+ volts at the battery you should have this same voltage at that fuse. See attachments at bottom.Battery Voltage Gauge OperationThe IPC displays the system voltage as received from the BCM over the GMLAN serial data circuit. If there is no communication with the BCM then the gauge will indicate minimum.This vehicle is equipped with a regulated voltage control (RVC) system. This will cause the voltmeter to fluctuate between 12 and 14 volts, as opposed to non-regulated systems which usually maintain a more consistent reading of 14 volts. This fluctuation with the RVC system is normal system operation and NO repairs should be attempted.

Please Log in or Create an account to join the conversation.

- jd64

-

Topic Author

- Offline

- New Member

-

- Posts: 17

- Thank you received: 1

Please Log in or Create an account to join the conversation.

- jd64

-

Topic Author

- Offline

- New Member

-

- Posts: 17

- Thank you received: 1

Finally had a minute to test the following, Each was tested using a homemade extension/lead from the ground. This is to limit the fluctuation by not touching the metal right at each location. These were all done with the vehicle having sit for about 2 weeks without anything being touched.

The system had just got woken by me opening the door and can see by the end of the test it was going back into sleep by the voltage increase.

1st picture is + to - across the battery using the extension for ground.

2nd is to batt volt on alternator

3rd is fusebox hot leg

4th IPC 46 Fuse

5th is the homemade voltmeter in the cigarette lighter

6th is measurement of the back side of the voltmeter just to keep everything in perspective (also system is a sleep and battery is recovering)

Please Log in or Create an account to join the conversation.

- jd64

-

Topic Author

- Offline

- New Member

-

- Posts: 17

- Thank you received: 1

Please Log in or Create an account to join the conversation.

- ferris48

-

- Offline

- Premium Member

-

- Posts: 129

- Thank you received: 47

Please Log in or Create an account to join the conversation.

- jd64

-

Topic Author

- Offline

- New Member

-

- Posts: 17

- Thank you received: 1

Please Log in or Create an account to join the conversation.

- jd64

-

Topic Author

- Offline

- New Member

-

- Posts: 17

- Thank you received: 1

Hope to upload and explain this weekend

Please Log in or Create an account to join the conversation.

- jd64

-

Topic Author

- Offline

- New Member

-

- Posts: 17

- Thank you received: 1

Please Log in or Create an account to join the conversation.

- jd64

-

Topic Author

- Offline

- New Member

-

- Posts: 17

- Thank you received: 1

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4992

- Thank you received: 1115

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- jd64

-

Topic Author

- Offline

- New Member

-

- Posts: 17

- Thank you received: 1

Please Log in or Create an account to join the conversation.

- jd64

-

Topic Author

- Offline

- New Member

-

- Posts: 17

- Thank you received: 1

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4992

- Thank you received: 1115

I think Tyler just had a run of bad aftermarket alternators charging over 15v and had to through quite a few to get one that charged at a lower rate.

Are there any codes or symptoms you are after, or are you just not happy with high charging voltage?

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6090

- Thank you received: 1538

From GM theory and operation:

Charge Mode

The BCM will enter Charge Mode when ever one of the following conditions are met.When any one of these conditions is met, the system will set targeted generator output voltage to a charging voltage between 13.9–15.5 V, depending on the battery state of charge and estimated battery temperature.

- The wipers are ON for more than 3 seconds.

- GMLAN (Climate Control Voltage Boost Mode Request) is true, as sensed by the HVAC control head. High speed cooling fan, rear defogger and HVAC high speed blower operation can cause the BCM to enter the Charge Mode.

- The estimated battery temperature is less than 0°C (32°F).

- Battery State of Charge is less than 80 percent.

- Vehicle speed is greater than 145 km/h (90 mph)

- Current sensor fault exists.

- System voltage was determined to be below 12.56 V

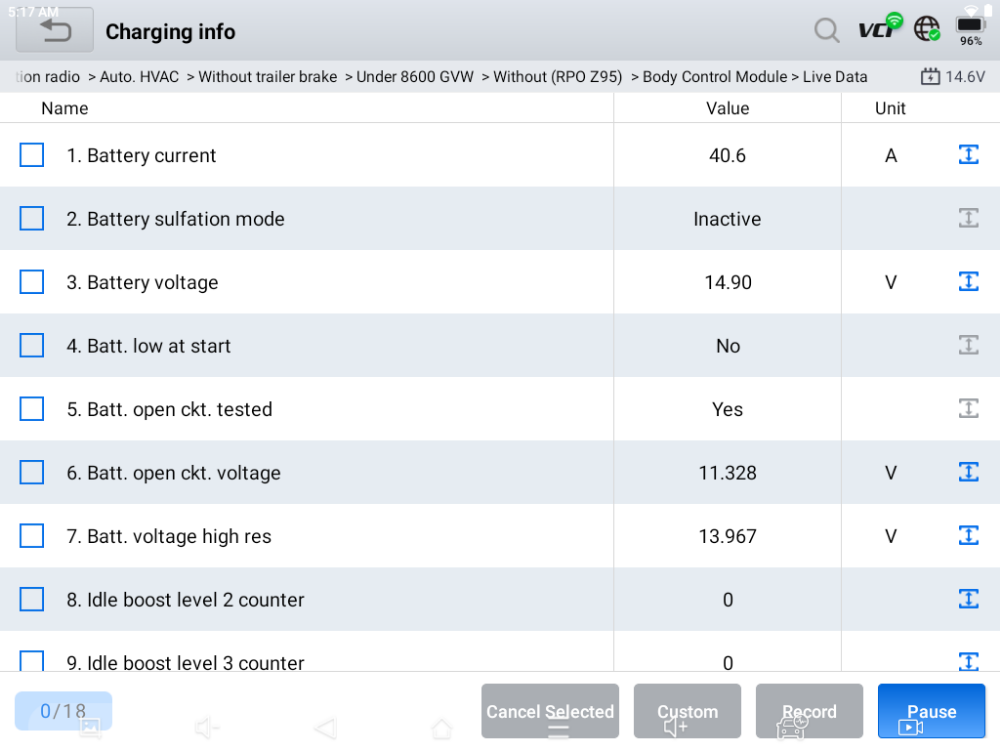

I did see in a couple of your captures that the State of Charge was at 70%. The BCM wants it at 80% or higher. Also saw the open circuit voltage was 11.3V at one point.

Has the battery been replaced with new? If so, which brand/model?

Please Log in or Create an account to join the conversation.

- Echo1

-

- Offline

- New Member

-

- Posts: 4

- Thank you received: 0

Please Log in or Create an account to join the conversation.

- jd64

-

Topic Author

- Offline

- New Member

-

- Posts: 17

- Thank you received: 1

In short the fact I can have a battery charger charge the battery (2nd new battery) for 24hrs and crank the truck and it continue to charge at 15.0+ volts for more than an hour is an issue.I do see GM vehicles charging around 15v without issue.

I think Tyler just had a run of bad aftermarket alternators charging over 15v and had to through quite a few to get one that charged at a lower rate.

Are there any codes or symptoms you are after, or are you just not happy with high charging voltage?

Please Log in or Create an account to join the conversation.

- jd64

-

Topic Author

- Offline

- New Member

-

- Posts: 17

- Thank you received: 1

The battery has been replaced twice and need to get the last brand/model for the response. (updated) Duralast H6-DLG Din H6 En ln3 BCI 48 730 CCAmpsWhen I see GM's with the charging system voltage above 15V, it's usually in response to a weak battery. There's other things that can it, too, but that's the most common one, in my experience.

From GM theory and operation:Charge Mode

The BCM will enter Charge Mode when ever one of the following conditions are met.When any one of these conditions is met, the system will set targeted generator output voltage to a charging voltage between 13.9–15.5 V, depending on the battery state of charge and estimated battery temperature.

- The wipers are ON for more than 3 seconds.

- GMLAN (Climate Control Voltage Boost Mode Request) is true, as sensed by the HVAC control head. High speed cooling fan, rear defogger and HVAC high speed blower operation can cause the BCM to enter the Charge Mode.

- The estimated battery temperature is less than 0°C (32°F).

- Battery State of Charge is less than 80 percent.

- Vehicle speed is greater than 145 km/h (90 mph)

- Current sensor fault exists.

- System voltage was determined to be below 12.56 V

I did see in a couple of your captures that the State of Charge was at 70%. The BCM wants it at 80% or higher. Also saw the open circuit voltage was 11.3V at one point.

Has the battery been replaced with new? If so, which brand/model?

I am tracking the triggers for the charge modes. No AC, idling, lights to include daytime and interior off, no radio, wipers or defrost either.

(Correction I found it) I did not see the 11.3 screenshot but did see 11.5. This was when I 1st started looking at the truck and it had been sitting and then opened the door so the system woke.

Please Log in or Create an account to join the conversation.

- jd64

-

Topic Author

- Offline

- New Member

-

- Posts: 17

- Thank you received: 1

Have not load tested but has been replaced with an AGM and acid flooded battery.Have you load tested the battery?

Please Log in or Create an account to join the conversation.