3.5 Ecoboost swap project trouble

- matt.nelson

-

Topic Author

- Offline

- New Member

-

- Posts: 12

- Thank you received: 3

Back around the time of covid I ended up swapping a 3.5 ecoboost/6R80 into my beloved 2001 F150. I sent the harness off to a guy who had it all ironed out and the first time I connected it all on the garage floor it started up without issue. It ran in such a fashion for about 4 years. Never once left me stranded! That all changed about 2 months ago when I was driving along (all peaceful like) and it died. I towed it back home and figured it was a fuse or relay or something easy. Well, none of that was wrong. It cranks, no spark. No codes.

I started looking into it, hooked up Forscan, LiveLink and tried to pull data. I got out my multimeter and followed the AllData directions for checking the ignition circuit. No shorts to power or ground. At this point it looked like a PCM fault, so I swapped it out with a 'tested' used one, had PATS (security lock out) disabled and tried again - same. Crank, no spark. Looked into it more (found nothing) and became afraid that a bad coil might be ruining the PCM just as I plugged it in. So I bought another PCM (luckily they are pretty cheap) and tried it all again - same result. (Whats the definition of an idiot?) I can provide 5v to the coil signal wire and it will spark, so there is no reason to believe that circuit is faulty that I can tell. It is just not getting the 5v signal from the PCM.

I noticed that there is no cam position data available. (It reads RPM while cranking so I see no reason to believe the crank sensor is bad) Cam data reads all zeroes while cranking. I tried this on a 2018 (ecoboost, but newer generation) truck and the cam data populates during cranking. Back on the swap project, it does show cam/crank as in 'sync' while cranking and 'no' while not cranking. But all of those zeroes. Also, 'no fault' shows in Forscan for all cam sensors whether they are plugged into the harness or not. So much for these 'amazing' computers, huh?!

So I'm really, really stuck. AllData gives a procedure for checking the cam circuit. I cannot find anything wrong there. There are three wires going to each cam sensor. One buffered VREF, one signal return and one wire that runs directly back to the PCM from each sensor. Everything appears normal here, but I am getting +12v from the PCM going to each sensor on that direct 'sensor to PCM' wire. Perhaps this is normal?

I really don't know where else to go with this one. Does anyone have any idea what to do next?

Please Log in or Create an account to join the conversation.

- Noah

-

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4992

- Thank you received: 1115

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- matt.nelson

-

Topic Author

- Offline

- New Member

-

- Posts: 12

- Thank you received: 3

The engine and trans and harness and ECU came from a 2017 Ford Expedition. The Expedition remains considered a 'Gen 1' Ecoboost despite the 2017 F150 turning to the 'Gen 2' motor.

To add further: AllData lists the symptom based procedure to diagnose a crank no spark condition. It asks for VREF and Return at the throttle position sensor. Checked. It asks for Voltage at the coil circuit and free of shorts to ground or voltage. Checked. It asks for Crank/Cam Sync PID and RPM PID. Check and check. I also verified that the PATS delete I did was not the cause for the no start. I did this by checking the Torque Source PID, which displays 0.

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6090

- Thank you received: 1538

I followed the Pinpoint Test A and JF in service info for the '17 Expedition and ended up where you did. JF wants coil replacement before PCM replacement, but I have a tough time with all six coils going bad at the same time...

Without a scope to do some more detailed testing, I can only throw some ideas out there. One would be to disconnect one CMP sensor at a time and crank the engine again. See if the 'SYNC' PID changes, or if the PCM sets a corresponding code. Do the same with the CKP if none of the CMPs change anything. I'm hoping that either the data/fault codes will show that the CMP/CKP sensor signal is missed by the PCM, or that the engine will start. If the PCM shows it's missing a sensor signal, you can have confidence that the sensors are at least trying. If the engine starts with one or more sensors disconnected, you're probably onto something.

Please Log in or Create an account to join the conversation.

- matt.nelson

-

Topic Author

- Offline

- New Member

-

- Posts: 12

- Thank you received: 3

After a little reading here I can clearly tell I've got a lot of learning to do. Haha. Given the complex and time consuming nature of some of these electrical failures it is either a DIY fix or a huge bill due to the time required to get it ironed out. Wow.

Thanks for the reply and ideas. I was thinking along those same lines earlier and unplugged three of the four cam sensors and still saw the SYNC PID display as usual. Unfortunately the 4th one is a real bugger to get to but I can go and pull the signal wire from the PCM pin and crank again to see if the PID remains. Will do that tomorrow. I already cranked with the CKP unplugged which showed no DTC's.

Earlier I noticed that the PCM was supplying 5v to a cam signal wire. Its a 3 wire hall sensor, so this would be normal operation (a 'pull down') correct?

I'll also be checking the signal return wire of that circuit for errant voltage as well.

Oh - also - I, too, found it hard to believe that 6 coils could all be bad so I connected them to the harness and with the ignition on I supplied +5v to the signal wire (multiple told me it was signaled with a ground but I found different) and saw spark. So this definitely seems to be a PCM related issue, whether or not it is for a good reason remains TBD. For what it is worth, I noticed that all 6 of the Coil signal wires had right around .155v present. The manual asks 'Is any voltage present?' My assumption that .155v would have required a 'no' answer. But some things have me rethinking that. Any ideas?

Finally, I read that it is important that the PCM have no connection to a ground around the case. I had no idea about this and will be adjusting things accordingly.

Will keep after it and advise.

Merry Christmas!

Please Log in or Create an account to join the conversation.

- matt.nelson

-

Topic Author

- Offline

- New Member

-

- Posts: 12

- Thank you received: 3

Ugh.

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6090

- Thank you received: 1538

Oh - also - I, too, found it hard to believe that 6 coils could all be bad so I connected them to the harness and with the ignition on I supplied +5v to the signal wire (multiple told me it was signaled with a ground but I found different) and saw spark.

That's good enough for me! It also indirectly rules out a coil B+ and ground circuit issue, IMO. And (kinda) rules out a short to ground on the coil control circuit.

For what it is worth, I noticed that all 6 of the Coil signal wires had right around .155v present. The manual asks 'Is any voltage present?' My assumption that .155v would have required a 'no' answer. But some things have me rethinking that. Any ideas?

I would rate that as no voltage. Or close enough, anyway. I don't know what voltage/current the coil requires on the control circuit to field the coil, but I'm gonna figure 155 mV isn't enough.

Test JF8 - Checking the coil control for a short to ground - What was your resistance reading?

I think so? Honestly, I've never had a reason to check the CMP sensors on 3.5L engines.Earlier I noticed that the PCM was supplying 5v to a cam signal wire. Its a 3 wire hall sensor, so this would be normal operation (a 'pull down') correct?

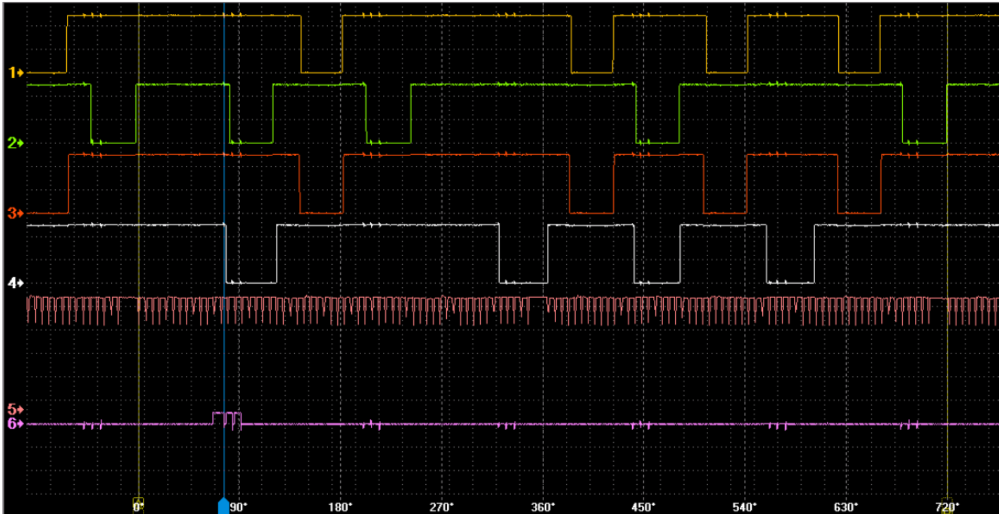

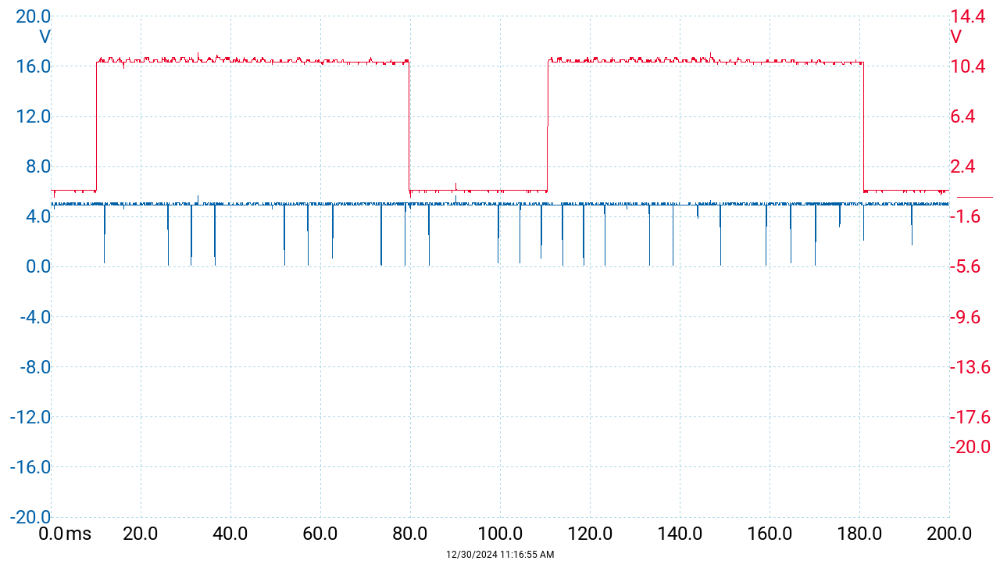

I got a known good cam/crank waveform from Rotkee. It appears that the CMP signals spend most of their time at 5.0V, so I'd tend to think they are pull down:

So I disconnected all 4 cam sensors and cranked and it did not read 'sync.'

Interesting. It's a pretty rough test, but that tends to make me think that this is not a timing or CMP/CKP input problem.

It sounds weird, but I'd be interested to know what the fuel injectors are doing. I don't doubt that the lack of spark is a problem, I just like to know about spark AND injector pulse as an indicator of PCM operation. Trying to figure out of we should go down the input or output path.

Actually verifying injector pulse on this engine is gonna require a scope. I don't know that a meter or test light will cut it. There are PIDs for injector pulse width. FUELPW1 and FUELPW2. If they're reporting a non-zero value, then that'd suggest the PCM wants the engine to start. If they're zero, then that'd suggest an input problem. To be clear, I don't fully trust the FUELPW1/2 PIDs. Just because they're not zero doesn't mean pulse is actually happening.

Alternately, you could go old school and pull a spark plug. Is the plug wet with fuel? Then that'd suggest fuel is flowing. If it's dry, then that suggests a lack of injector pulse.

Please Log in or Create an account to join the conversation.

- matt.nelson

-

Topic Author

- Offline

- New Member

-

- Posts: 12

- Thank you received: 3

Interesting thoughts on the fuel. Makes sense, too. If it is some errant line of code or a tuning issue the PCM wouldn't even be allowing fuel (one would think!) I did take a sniff of the exhaust pipe after some cranking and definitely smelled fuel. I'll do a better test tomorrow with the computer and/or a spark plug.

I tried to backprobe a few of the other REF circuits just to look for something (anything!) out of sorts. My needles must not be long enough or something because its pretty tough to get a good reading out the back of the PCM connector. I usually just end up going to a nearby sensor and try there.

Thanks for the advise. This will be one for the books.

Please Log in or Create an account to join the conversation.

- matt.nelson

-

Topic Author

- Offline

- New Member

-

- Posts: 12

- Thank you received: 3

During this test I also pulled a plug and stuffed a paper towel down the hole. It did not smell of gasoline after cranking. To be sure, I pulled the next plug and it seemed dry after the cranking as well.

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6090

- Thank you received: 1538

For that (JF8) COP signal wire to battery ground test I saw no continuity.

Awesome, I appreciate the clarification. Mostly, I was imagining a resistive short to ground on the coil control circuits. Not enough to flag as a problem in the JF chart, and resistive enough that you could overcome it by using the 5V reference on that circuit while making the coil spark. Not a very likely scenario, just thinking outside the box.

I think you're good? I've never ohm tested a block ground with the key on, as I think that's technically an invalid test (live circuit). Anyway, I'd figure that the engine wouldn't be cranking if the block ground resistance was actually that high.The meter didn't move. I did notice earlier that with the ignition off there is 5-10 ohms of resistance between battery negative and the block and 50-70 ohms when the ignition is turned on. The big battery to engine ground is quite solid. Not sure what else might be at fault there, if anything.

I looked for those PID's in my LiveLink log program. They were not there, but 'Injector Pulsewidth' was available. So I logged that. It remained at zero during cranking.

During this test I also pulled a plug and stuffed a paper towel down the hole. It did not smell of gasoline after cranking. To be sure, I pulled the next plug and it seemed dry after the cranking as well.

Well isn't that interesting. If you were missing only spark, those plugs should be dripping with fuel by now.

Again, it's a rough test, but that kinda puts me back on the input path. Thinking out loud, there's only a few reasons I can think of why you'd be missing both spark and injector pulse:

- Clear flood mode. You're probably not putting it in clear flood mode, but the APP could be misreporting somehow. Ford has a 'DECHOKE' data PID that'll tell you if cranking fueling is disabled. You can also look at the APP % and APP_MODE.

- Anti-theft. It doesn't explain the initial stall, and you said you disabled the PATS. If you go into BCM data and look at the 'START_ENABLD' PID, what does it say?

- Back to cam/crank. Not sure of a better way to test this without a scope.

Please Log in or Create an account to join the conversation.

- matt.nelson

-

Topic Author

- Offline

- New Member

-

- Posts: 12

- Thank you received: 3

I logged that 'Dechoke' PID and it was 'No' while cranking. Also, APP was at 0 and would respond accordingly if I pressed on the throttle.

I was initially interested in seeing how a non-PATS-disabled PCM would show up during cranking, so I tried it before PATS removal. In Forscan, that box would say 'Disabled' prior to removal and afterwards the PATS box remains blank at all times. I was also told to log Torque Source and found evidence that is congruent with PATS not being the limiting factor.

So yes...back to Cam and Crank indeed.

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6090

- Thank you received: 1538

I also thought that it may be beneficial to check fuel rail pressure during a crank. It'd be nice to verify that source fuel pressure is good, and rail pressure can be an indirect indicator of timing chain health.

Please Log in or Create an account to join the conversation.

- matt.nelson

-

Topic Author

- Offline

- New Member

-

- Posts: 12

- Thank you received: 3

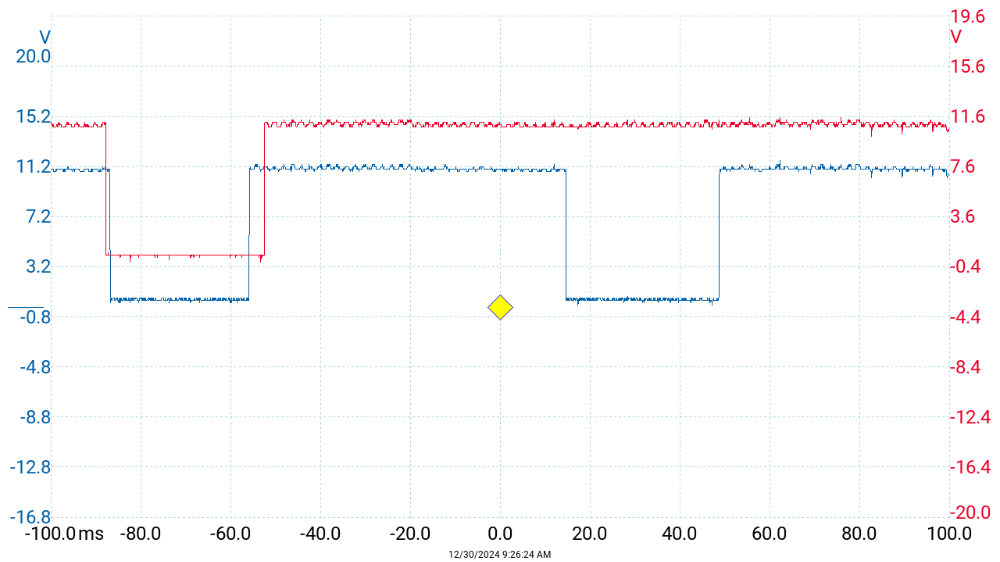

Channel A (Blue) set to the Bank 1 Exhaust Cam, Channel B (Red) set to the Crank. I cannot speak to proper cam/crank correlation, but the signal looks appropriate. Buffered VREF (11.5v) and the sensors get pulled down for a moment to zero. I suppose I could test the three other cam sensors but perhaps it is not necessary.

Also, during cranking I noticed that the 'DeChoke' PID moves back and forth between Yes and No. Also, rail pressure from the high pressure pump sits slightly above desired while cranking.

I've attached the Pico file here.

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

- Posts: 6090

- Thank you received: 1538

From your capture, I'm not sure that you're actually probed into the CKP circuit? There's not nearly enough frequency in the signal to match the known good I posted earlier, or any other known good I can find. The CKP should be transitioning several times within the blue CMP pulse.

Either that, or something is really wrong with the CKP signal.

Please Log in or Create an account to join the conversation.

- matt.nelson

-

Topic Author

- Offline

- New Member

-

- Posts: 12

- Thank you received: 3

I ended up calling a company who is into engine swaps and wiring and he seemed to think it was likely related to the PCM. I ended up sending him all (3!) of mine and he will look into them and sort things out. Apparently he has the means of bench testing them. I will update as things progress.

Please Log in or Create an account to join the conversation.

- matt.nelson

-

Topic Author

- Offline

- New Member

-

- Posts: 12

- Thank you received: 3

I am beyond frustrated.

I've checked all of the VREF and VBREF circuits forwards and backwards. I must be missing something or testing something wrong but I don't know what it is. I've ordered a used engine harness off Ebay (it was cheap) so I'll replace that and see if changing that variable yields any results.

Please Log in or Create an account to join the conversation.

- matt.nelson

-

Topic Author

- Offline

- New Member

-

- Posts: 12

- Thank you received: 3

Turns out that there was one bent tooth on the timing wheel. I have no idea how it happened, since the transmission has never been removed from the engine since it left the factory. The CKP must have just got tired of it and gave up. I pulled the trans, pulled the flex plate and bent the tooth back into place and replaced everything and the truck works beautifully now.

Shame on me...I should have worked to learn how to make the CKP signal clearer in the scope reading on the computer. I read so many times that if you see an RPM signal the CKP is good and I thought that the problem would lie elsewhere. Should have looked much more carefully at that CKP signal! It does seem a little odd to me that the PCM would not produce a code for seeing two TDC's per revolution. Something like CKP signal implausible. Ford, if you're reading this consider this programming change or even better make sure if you have a factory worker that drops a timing reluctor wheel on the floor make them get a new one instead of assembling an engine with a damaged one.

Cheers

Please Log in or Create an account to join the conversation.