Help us help you. By posting the year, make, model and engine near the beginning of your help request, followed by the symptoms (no start, high idle, misfire etc.) Along with any prevalent Diagnostic Trouble Codes, aka DTCs, other forum members will be able to help you get to a solution more quickly and easily!

Rough Engine Idling/Misfire & Engine Lacking Power

- Saverauto

-

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 51

- Thank you received: 0

3 years 1 month ago - 3 years 1 month ago #59139

by Saverauto

Rough Engine Idling/Misfire & Engine Lacking Power was created by Saverauto

Toyota Alphard

1MZ-FE engine

The complaint was that the engine was shaking, especially when transmission put into reverse.

TECH 1:

Scanned engine for error codes, none found.

No function in scan tool to carry out power balance test.

Bank 2 ignition coils were disconnected one-by-one to isolate possible misfire & there is no change when cylinder 4 disconnected.

It's an awkward engine because the manifold & air ducting has to be removed to access bank 1.

All spark plugs were removed & no carbon deposits due to misfire just wider spark plug gaps (0.1mm over spec).

No improvement after spark plugs replaced.

Bank 1 coils were moved to bank 2. Ignition coil disconnect was carried out & again no change when cylinder 4 disconnected.

KOEO, ignition coil 4 connector checked & all okay. For reference, connector on coil 2 checked & same readings.

Sprayed brakekleen in & around intake manifold & vacuum hoses. All okay

TECH 2:

Had a look at fuel trim data, LTFT bank 2 at 15%, LTFT bank 1 at 0.8%

Removed all injectors for testing & cleaning. All okay

When reinstalling injectors identified broken vacuum hose from EVAP canister to engine.

After replacing hose & cleaning injectors engine idle not as rough & fuel trim improved to 12.5%

Cylinder compression test was also carried out & all cylinders within spec

Owner of car was asked to test drive car & confirmed slight improvement in engine shaking but still lacking power.

TECH 3:

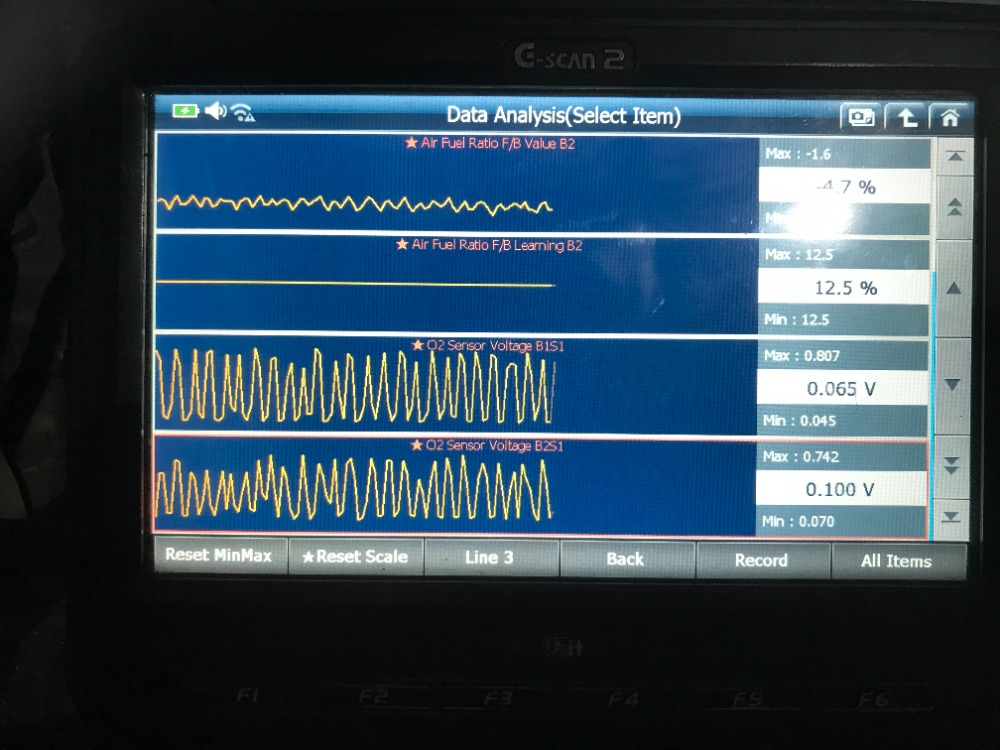

Ran O2 sensor live data. Cycling okay & responding when brakekleen sprayed into intake.

The second day ran O2 sensor live data again & B2S1 stuck at 0.00V. Sprayed brakleen into intake & B1S1 responds a lot but B2S1 barely budges up to 0.07V

Replaced B2S1 O2 sensor & sensor signal is back but the engine is shaking more than it did before O2 sensor was replaced

Bank 2 LTFT still stuck at 12.5%

Carried out individual VVT solenoid activation for both bank 1 & 2 & the engine rpm changes throughout test. The LTFT for bank 1 changes but bank 2 stays the same.

Bank 2 LTFT suggests a lean condition but most if not all possible causes have been looked at & tested.

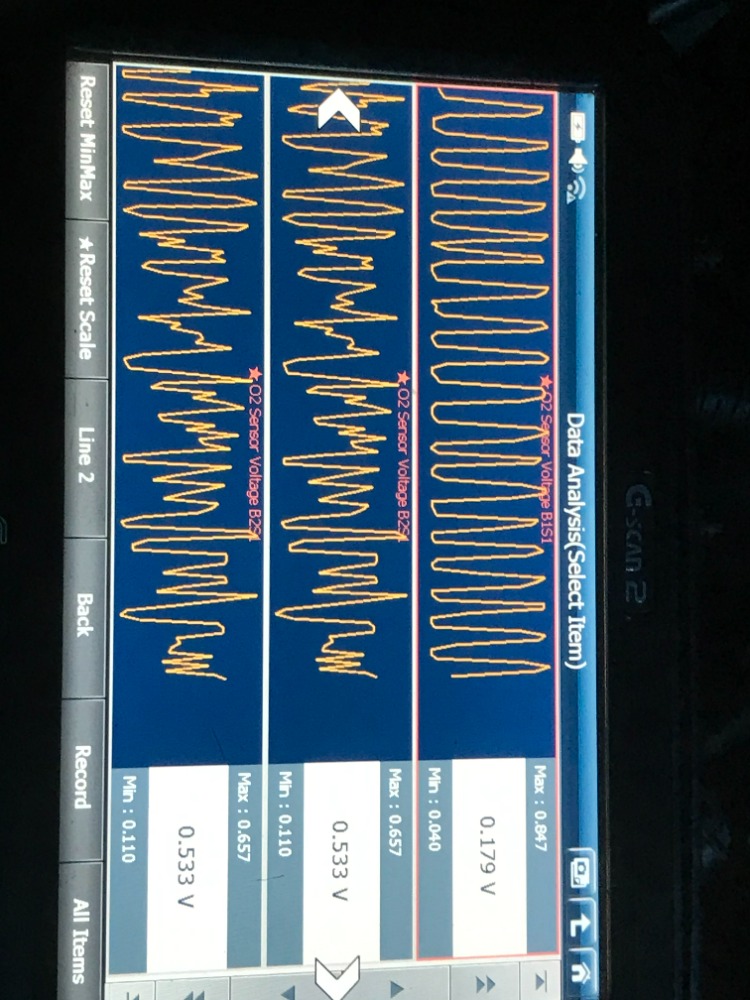

As far as the O2 sensor for bank 2 is concerned, it is genuine Toyota & wire colors are the same but there are less diffusion holes. There is no error code for the new sensor. It is however for a Harrier & not an Alphard but it is all that was available. What is noticed is that the sensor cycles when engine idling but the interval is narrower than bank 1. What I mean is that B1S1 cycles between 0.04 & 0.847 volts while B2S1 cycles between 0.110 & 0.657 volts. During a snap throttle, both sensors register a reading of 0.9 volts.

Attached are photos of the old & new sensor & the O2 sensor live data at idle:

Any idea what may be causing the LTFT to stay stuck at 12.5% & the engine to misfire/idle rough??

1MZ-FE engine

The complaint was that the engine was shaking, especially when transmission put into reverse.

TECH 1:

Scanned engine for error codes, none found.

No function in scan tool to carry out power balance test.

Bank 2 ignition coils were disconnected one-by-one to isolate possible misfire & there is no change when cylinder 4 disconnected.

It's an awkward engine because the manifold & air ducting has to be removed to access bank 1.

All spark plugs were removed & no carbon deposits due to misfire just wider spark plug gaps (0.1mm over spec).

No improvement after spark plugs replaced.

Bank 1 coils were moved to bank 2. Ignition coil disconnect was carried out & again no change when cylinder 4 disconnected.

KOEO, ignition coil 4 connector checked & all okay. For reference, connector on coil 2 checked & same readings.

Sprayed brakekleen in & around intake manifold & vacuum hoses. All okay

TECH 2:

Had a look at fuel trim data, LTFT bank 2 at 15%, LTFT bank 1 at 0.8%

Removed all injectors for testing & cleaning. All okay

When reinstalling injectors identified broken vacuum hose from EVAP canister to engine.

After replacing hose & cleaning injectors engine idle not as rough & fuel trim improved to 12.5%

Cylinder compression test was also carried out & all cylinders within spec

Owner of car was asked to test drive car & confirmed slight improvement in engine shaking but still lacking power.

TECH 3:

Ran O2 sensor live data. Cycling okay & responding when brakekleen sprayed into intake.

The second day ran O2 sensor live data again & B2S1 stuck at 0.00V. Sprayed brakleen into intake & B1S1 responds a lot but B2S1 barely budges up to 0.07V

Replaced B2S1 O2 sensor & sensor signal is back but the engine is shaking more than it did before O2 sensor was replaced

Bank 2 LTFT still stuck at 12.5%

Carried out individual VVT solenoid activation for both bank 1 & 2 & the engine rpm changes throughout test. The LTFT for bank 1 changes but bank 2 stays the same.

Bank 2 LTFT suggests a lean condition but most if not all possible causes have been looked at & tested.

As far as the O2 sensor for bank 2 is concerned, it is genuine Toyota & wire colors are the same but there are less diffusion holes. There is no error code for the new sensor. It is however for a Harrier & not an Alphard but it is all that was available. What is noticed is that the sensor cycles when engine idling but the interval is narrower than bank 1. What I mean is that B1S1 cycles between 0.04 & 0.847 volts while B2S1 cycles between 0.110 & 0.657 volts. During a snap throttle, both sensors register a reading of 0.9 volts.

Attached are photos of the old & new sensor & the O2 sensor live data at idle:

Any idea what may be causing the LTFT to stay stuck at 12.5% & the engine to misfire/idle rough??

Last edit: 3 years 1 month ago by Saverauto.

Please Log in or Create an account to join the conversation.

- Chad

-

- Offline

- Moderator

-

- I am not a parts changer.

Less

More

- Posts: 2129

- Thank you received: 715

3 years 1 month ago #59178

by Chad

"Knowledge is a weapon. Arm yourself, well, before going to do battle."

"Understanding a question is half an answer."

I have learned more by being wrong, than I have by being right.

Replied by Chad on topic Rough Engine Idling/Misfire & Engine Lacking Power

I would do a Relative Compression test. If you don't have a scope, disable fuel and crank the engine. Listen to the engine cadence. It should crank continuously and smoothly. If you hear a repetitive cadence, then you may have a single-cylinder compression issue.

"Knowledge is a weapon. Arm yourself, well, before going to do battle."

"Understanding a question is half an answer."

I have learned more by being wrong, than I have by being right.

Please Log in or Create an account to join the conversation.

- Saverauto

-

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 51

- Thank you received: 0

3 years 4 weeks ago - 3 years 4 weeks ago #59204

by Saverauto

Battery was disconnected overnight to reset LTFT. Engine still shakes & after running it LTFT eventually went back to 15%, from 0%.

Unfortunately we don't have the connector needed to obtain voltage readings from the AMP clamp.

Disconnected EFI relay & cranked car over...sounds pretty good.

Carried out another cylinder compression test on bank 2 cylinders. This time bank 1 spark plugs weren't removed due to the amount of work required to remove the manifold, throttle & ducting.

Cylinder 4 has lower compression than 2 & 6. I think 10-15 psi less than the others, if I can remember correctly.

Now going to carry out a cylinder leak down test.

Replied by Saverauto on topic Rough Engine Idling/Misfire & Engine Lacking Power

I would do a Relative Compression test. If you don't have a scope, disable fuel and crank the engine. Listen to the engine cadence. It should crank continuously and smoothly. If you hear a repetitive cadence, then you may have a single-cylinder compression issue.

Battery was disconnected overnight to reset LTFT. Engine still shakes & after running it LTFT eventually went back to 15%, from 0%.

Unfortunately we don't have the connector needed to obtain voltage readings from the AMP clamp.

Disconnected EFI relay & cranked car over...sounds pretty good.

Carried out another cylinder compression test on bank 2 cylinders. This time bank 1 spark plugs weren't removed due to the amount of work required to remove the manifold, throttle & ducting.

Cylinder 4 has lower compression than 2 & 6. I think 10-15 psi less than the others, if I can remember correctly.

Now going to carry out a cylinder leak down test.

Last edit: 3 years 4 weeks ago by Saverauto.

Please Log in or Create an account to join the conversation.

- Saverauto

-

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 51

- Thank you received: 0

3 years 4 weeks ago #59225

by Saverauto

Replied by Saverauto on topic Rough Engine Idling/Misfire & Engine Lacking Power

Just an update.

Cylinder leak down test was carried out on cylinder 4 - gauge was playing up but when the oil cap was opened, cold air could be felt.

Was about to condemn the piston rings but it was suggested that bank 2 coils be looked at again.

Cylinder 6 coil was disconnected & no change in engine rpm. Re-installed old cylinder 4 coil into cylinder 6 & engine smoothed out.

Interestingly enough the LTFT dropped from a static 15% to -3%...??

My question is: A LTFT of 15% suggests a lean condition because the ECU is adding fuel. If a coil is not firing OR providing a weak spark then there should be an excess of fuel. The LTFT should then be negative ??

Cylinder leak down test was carried out on cylinder 4 - gauge was playing up but when the oil cap was opened, cold air could be felt.

Was about to condemn the piston rings but it was suggested that bank 2 coils be looked at again.

Cylinder 6 coil was disconnected & no change in engine rpm. Re-installed old cylinder 4 coil into cylinder 6 & engine smoothed out.

Interestingly enough the LTFT dropped from a static 15% to -3%...??

My question is: A LTFT of 15% suggests a lean condition because the ECU is adding fuel. If a coil is not firing OR providing a weak spark then there should be an excess of fuel. The LTFT should then be negative ??

Please Log in or Create an account to join the conversation.

- Tyler

-

- Offline

- Moderator

-

- Full time HACK since 2012

Less

More

- Posts: 6064

- Thank you received: 1531

3 years 3 weeks ago #59266

by Tyler

That's one of the most counterintuitive aspects of fuel trim and misfires. :silly: In the case of either a no fuel OR a no spark misfire, the fuel trims on that bank will go positive.

There's a lot of theory that goes into the explanation. Short version, yes there's unburned fuel going into the exhaust during a no spark misfire. But there's also a lot of unburned air. The oxygen sensor doesn't sense fuel, it senses air, therefore showing lean.

Replied by Tyler on topic Rough Engine Idling/Misfire & Engine Lacking Power

My question is: A LTFT of 15% suggests a lean condition because the ECU is adding fuel. If a coil is not firing OR providing a weak spark then there should be an excess of fuel. The LTFT should then be negative ??

That's one of the most counterintuitive aspects of fuel trim and misfires. :silly: In the case of either a no fuel OR a no spark misfire, the fuel trims on that bank will go positive.

There's a lot of theory that goes into the explanation. Short version, yes there's unburned fuel going into the exhaust during a no spark misfire. But there's also a lot of unburned air. The oxygen sensor doesn't sense fuel, it senses air, therefore showing lean.

The following user(s) said Thank You: Saverauto

Please Log in or Create an account to join the conversation.

- Saverauto

-

Topic Author

- Offline

- Senior Member

-

Less

More

- Posts: 51

- Thank you received: 0

3 years 3 weeks ago #59274

by Saverauto

Replied by Saverauto on topic Rough Engine Idling/Misfire & Engine Lacking Power

What you said makes sense. I’ll have a look at the video you posted too.

Please Log in or Create an account to join the conversation.

Time to create page: 0.251 seconds