Basic Diagnostic Tool Set

- Noah

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4997

- Thank you received: 1116

So you've got the diagnostic mind set, that's why we're all here after all. But what's in your diagnostic tool set?

Do you need that $100 test light that the tool truck vendor swears will fix the car for you and grab you a celebratory beer out of fridge after a job well done?

Should you go ahead and order that $500 fuel pressure & flow gauge test kit you saw your favorite YouTube Certified Technician use that one time?

Well, we've compiled a list of tools that we feel are essential to a basic diagnostic tool box! This isn't anything set in stone. Just like everything else, there are going to be variables. I've linked in some examples from the TOOLS section at the top of the page, but this is in no way a sales pitch! Feel free to expand or exclude as you see fit, and please, contribute to the list!

OBD scan tools and code readers are not going to be on this list. Do you need one? Yes! But the features and functions vary so much depending on your budget and involvement in auto repair, that it will be best handled in another thread.

The first thing not to be overlooked is hand tools! You're not going to get very far in your diagnosis if you can't gain access to the system or components you intend to test. I'm going to touch briefly on what I feel I use most during diagnosis, not necessarily repair work. That's why I'm going to exclude some things like 1/2" drive tools and wrenches.

At the very least, you should already own:

-Screwdrivers. Phillips and Flathead. The more the better, of all sizes!

- 1/4" drive socket set. Metric is king! Beware of discount sets that skip sizes, they always seem to skip the one you need the most.

A good set should contain shallow and deep sockets ranging from 4mm to 14mm. (A 5.5 doesn't always come in a set, be sure to add one!)

Of course a ratchet and a few different length extensions will round off this set.

-3/8" drive socket set. Much the same as the 1/4" set, metric is key. From 8mm up to 19mm should cover most everything too large for 1/4" drive tools. Make sure the set has ALL the sizes in order. I've seen them exclude 14mm, 16mm, 17mm... Don't get stuck without the sizes you need! And naturally, a ratchet and some extensions will round out this kit.

And while we're talking sockets, at some point you're going to need some some spark plug sockets! 5/8ths and 9/16ths are two most common plug sizes I see, and can get you through most jobs before you need to invest in a dedicated spark plug socket set.

-Torx and Allen. I prefer torx and allen sockets over drivers, but they each have their place and use. To each their own!

-Pliers. There's a lot of different pliers out there! But have a set of pliers that will open and close enough to pull off pinch style hose clamps. Some vise grip (needle nose type and blunt jawed ones) and channel lock style pliers are always useful, as well as a set of side cutters. Sometimes it's easier and more cost effective to buy a set containing multiple different pliers styles.

Of course, one can never have enough hand tools, so feel free to expand on this list to fit your needs!

So, you've got your tool set together, great! Now no air cleaner intake tube or wire harness hold down will stop you from testing that relay control circuit!

On to the testing equipment then!

First thing's first, #1 in the kit, tried and true!

-Test light. An incandescent type bulb with a tungsten filament like the one HERE . This will go a long way to verifying the presence and integrity of power and ground. As Scanner Danner has shown us, it can be used to check for spark, to apply power in low current circuits, and activate ground side switched components. This can also be used in the place of a noid light, which did NOT make this list.

-Multimeter. This is another expansive topic, but there are a few key features to look for in a multimeter. You're going to want one with a fused amp meter. Duty cycle will be a valuable feature in certain scenarios.

David Hobbs of Motor Age Magazine penned a recent article regarding the choice of a quality automotive multimeter. I'll link in the article HERE .

This is his top ten features in a meter, just in case you don't feel like reading that article right now:

Top 10 essential functions to look for in a DMM

Auto Off Function — keeps the meter’s battery from running down constantly

Auto Ranging Capabilities — reduces confusion when testing unfamiliar circuits

Min/Max/Average — for capturing intermittent problems

Hold Button — Allows user to quickly press a button to freeze whatever is on the display

Frequency and Duty Cycle — for pulsing DC square waves and AC sine waves

Fuses for Ammeter’s High and Low Current settings – prevents the meter from being ruined

Analog Bar Graph — for a visual quick look when testing

Diode test capabilities – to forward bias diodes while testing (superior to ohmmeter test)

Category III/1,000 Volt (or higher) rated — for working on hybrid / EV systems

True RMS rated — provides more accurate AC measurements

Andy turned Tyler and Myself onto this Owon bluetooth capable meter . It's been great for me, but is not by any means the only one out there.

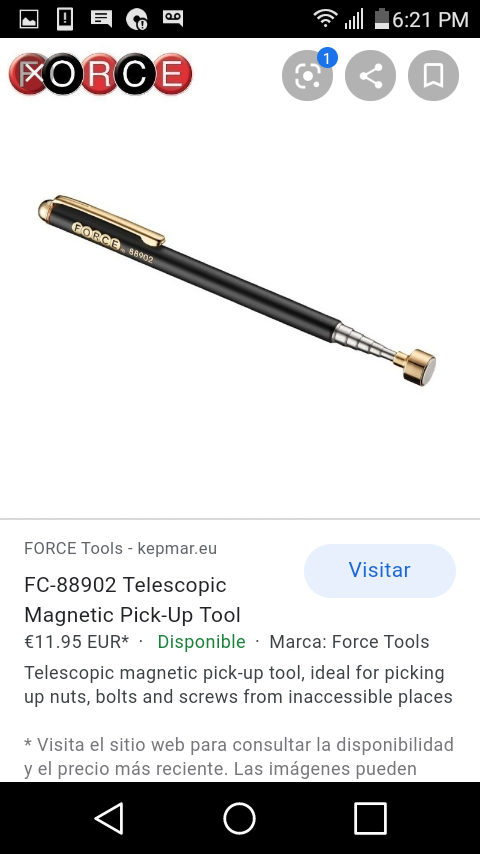

-Back probes or T-pins. You can make them, you can buy them (HERE for example) but you need to have them! They're your window into the functioning circuit, and without them, you'll be forced to break to the circuit to make your checks.

-Spark tester. THIS is the one that I use. An adjustable spark tester like this will give you a much better idea of the quality of spark as opposed to some of the bulb type inline spark testers on the market. As mentioned before, a testlight can be used for a down and dirty test if you don't have one of these yet.

-Fuel pressure gauge. 100% necessary if you're serious about fixing cars! I don't know how many complaints I've seen that were related to low fuel pressure. From no starts, misfires, low power complaints, stalling, check engine lights....

You don't have to run right out and blow a week's pay on a professional quality gauge and adapter set, but at least have a low cost unit like THIS one available from Home Depot. With a little ingenuity, you'll be able to T into at least a handful of the cars you'll encounter.

-Vacuum gauge. I don't think that there's an easier to use or more cost effective tool you can have to verify the mechanical health of an engine than a VACUUM GAUGE . I can think of many instances where money and time was wasted on ignition components and computer controlled devices when a quick check on the intake manifold would have revealed valvetrain related damage early on in the diagnosis. It can be used to identify a multitude of issues in the right hands. I mainly use mine early on in misfire diagnosis, and to help ID restricted exhaust.

-Compression gauge. Again, the top end Snap-On kit is probably unrealistic to the average DIY'er or somebody just becoming initiated into the art, but there are plenty of much more attainable units even at your local parts store. Again, if you can't verify the integrity of the engine, you could end up sinking a good deal of time and money into a problem that can't be fixed with solenoids or sensors!

Jumper wires. With alligator clamps on the ends. Again, homemade will do the job, but you can always go out and buy some.

Spray bottle. Great for finding all manner of vacuum leaks! Also handy for finding failing secondary ignition components like spark plug wires

Brake Cleaner Or carb cleaner, or a propane torch (handy any way!) to artificially enrich the air fuel mixture, or try to determine if a no start is being caused by a no fuel situation.

Fuses. Yup. You're going to need them

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- bruce.oliver

-

- Offline

- Elite Member

-

- Posts: 318

- Thank you received: 88

Please Log in or Create an account to join the conversation.

- Chad

-

- Offline

- Moderator

-

- I am not a parts changer.

- Posts: 2155

- Thank you received: 723

I have one thing to add. Information. A subscription to ShopKey, All Data, a ScanneDanner premium channel

Arm yourself with knowledge BEFORE you go into battle.

"Knowledge is a weapon. Arm yourself, well, before going to do battle."

"Understanding a question is half an answer."

I have learned more by being wrong, than I have by being right.

Please Log in or Create an account to join the conversation.

- wgeno07

-

- Offline

- New Member

-

- Posts: 3

- Thank you received: 1

Please Log in or Create an account to join the conversation.

- Noah

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4997

- Thank you received: 1116

Sure, they'll call you right up and let you know that the car won't start, but they won't tell you they left the key on all night because "it doesn't run anyway, who cares?"

Hard to diag any complaint with a dead battery. Be prepared for that curve ball.

I currently use a Cornwell jump pack, which is just rebadged Midtronics unit (and is nearly identical to the Snap-On jumper for a fraction of the cost).

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- FlyinHawaiian

-

- Offline

- New Member

-

- Posts: 13

- Thank you received: 3

Please Log in or Create an account to join the conversation.

- EricGoodrich

-

- Offline

- Premium Member

-

- Posts: 118

- Thank you received: 49

You can get by with very little and I've done more with nothing than some have with tens of thousands of dollars in tools. Once, I diagnosed a bad ignition coil on an ATV in the woods by taking the gear indicator bulb and wiring off it and using it as a test light. But, if you really want to be accurate and fast you need to be willing to spend money where it counts.

Diagnostic tools aren't toys, they are investments that make us money. If you're a hobbyist or just want to fix your own cars you probably don't need to spend two grand on a Picoscope. It would be cheaper to load up the parts cannon. But if you do this for a living you're going to have to spend some cash.

Please Log in or Create an account to join the conversation.

- wes p

-

- Offline

- Junior Member

-

- Posts: 22

- Thank you received: 3

Please Log in or Create an account to join the conversation.

- Andy.MacFadyen

-

- Offline

- Moderator

-

- Posts: 3353

- Thank you received: 1037

" We're trying to plug a hole in the universe, what are you doing ?. "

(Walter Bishop Fringe TV show)

Please Log in or Create an account to join the conversation.

- Desmond6004

-

- Offline

- Platinum Member

-

Getting involved in discussions because I have a lot to learn still.

Please Log in or Create an account to join the conversation.

- tmcquinn

-

- Offline

- Premium Member

-

- Posts: 111

- Thank you received: 29

How about getting rid of all chrome tipped screwdrivers and getting the ones with black tips that don't just immediately ruin every screw head?

"I'll never know it all but I'm willing to settle for knowing where to find the answer!"

Please Log in or Create an account to join the conversation.

- Noah

-

Topic Author

Topic Author

- Offline

- Moderator

-

- Give code definitions with numbers!

- Posts: 4997

- Thank you received: 1116

I don't have any trouble with rounding out screws since I stopped buying cheap screwdrivers. I've had my Snap On set a few years now, (chrome tipped) and while it was hard to justify the cost at the time, It has proven to be a good investment.

Same goes for the wrench set.

"Ground cannot be checked with a 10mm socket"

Please Log in or Create an account to join the conversation.

- tmcquinn

-

- Offline

- Premium Member

-

- Posts: 111

- Thank you received: 29

"I'll never know it all but I'm willing to settle for knowing where to find the answer!"

Please Log in or Create an account to join the conversation.

- Andy.MacFadyen

-

- Offline

- Moderator

-

- Posts: 3353

- Thank you received: 1037

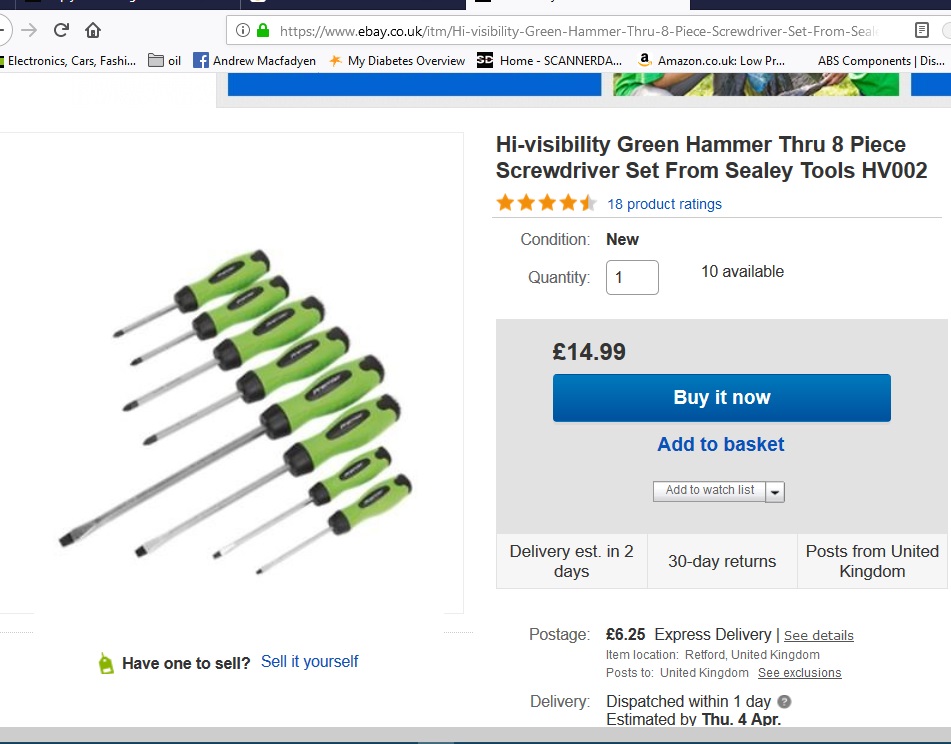

With crosshead, Phillips and Pozidrive screws using the correct size and style of driver is tricky. Even this list is not complete en.wikipedia.org/wiki/List_of_screw_drives . I generally look for "Hammer Through" screwdrivers as before trying to undo any screw on solid metal part I settle driver into the slot with suitable judged hammer blow. Another trick uncooperative screws is to use a tiny amount grinding paste on the tip of the screwdriver to give more grip , I believe there is a specialist product for this use called "Screw Grip" or "Screw Grab" or "Ez-Grip" but I have no experience of it.

For brake drum and disc retainer screws an other solid screws on of these should be in every too drawer.

" We're trying to plug a hole in the universe, what are you doing ?. "

(Walter Bishop Fringe TV show)

Please Log in or Create an account to join the conversation.

- tmcquinn

-

- Offline

- Premium Member

-

- Posts: 111

- Thank you received: 29

"I'll never know it all but I'm willing to settle for knowing where to find the answer!"

Please Log in or Create an account to join the conversation.

- Andy.MacFadyen

-

- Offline

- Moderator

-

- Posts: 3353

- Thank you received: 1037

For the heavy duty jobs such as brake drum screws

There are a couple of other options the quick and dirty one is use a little grinding paste on the tip to increase friction. there are also commercial products "Ez-Grip" , "Screwgrab" "Gettagrip" and others but I have never tried these.

" We're trying to plug a hole in the universe, what are you doing ?. "

(Walter Bishop Fringe TV show)

Please Log in or Create an account to join the conversation.

- chasencai

-

- Offline

- New Member

-

- Posts: 7

- Thank you received: 3

Please Log in or Create an account to join the conversation.

- kjack

-

- Offline

- New Member

-

- Posts: 1

- Thank you received: 0

Please Log in or Create an account to join the conversation.

- Andy.MacFadyen

-

- Offline

- Moderator

-

- Posts: 3353

- Thank you received: 1037

" We're trying to plug a hole in the universe, what are you doing ?. "

(Walter Bishop Fringe TV show)

Please Log in or Create an account to join the conversation.

- guafa

-

- Offline

- Platinum Member

-

- Posts: 477

- Thank you received: 80

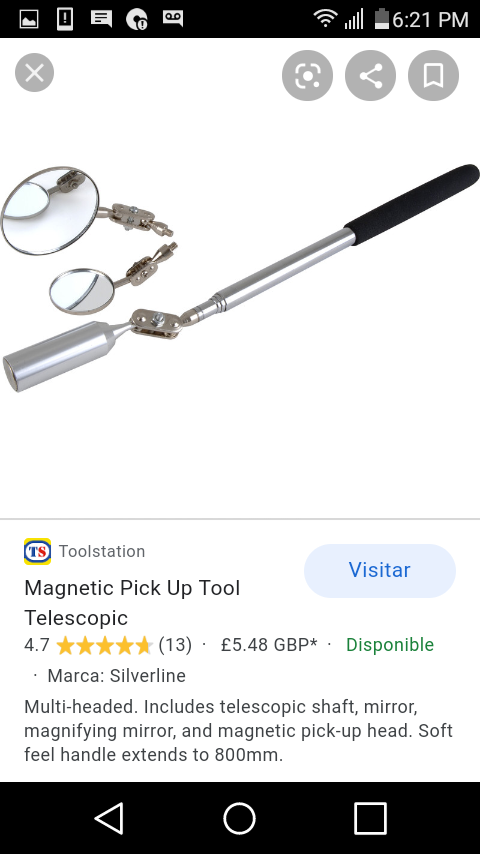

They can save you to much time even in diagnostics.

Please Log in or Create an account to join the conversation.